CHAPTER 7

DESIGN OF NORMAL

CONCRETE MIXTURE

L. Dvorkin and O.Dvorkin

7.1. General and tasks

Design of concrete mixtures - the main technological problem, which decision

defines a level of operational reliability of constructions and degree of rational

use of the resources spent for their manufacturing and installation.

The founder of practical methodology of design of concrete mixtures is

D.Abrams. He summarized results of extensive experimental researches in

Chicago Laboratory of Portland cement Association and formulated the

primary tasks of design of concrete mixtures and methods of their decision.

In modern technology designing of concrete mixture means a

substantiation and choice of a kind of initial materials and their ratios

providing at set criterion of an optimality given requirements to a concrete

mix and concrete.

127

Actual directions of development of methodology of concrete mixtures design

are:

- increase in "predicting ability" of calculated methodology that is an opportunity

of full comsideration of technological factors and given requirements to

concrete;

- increase in efficiency of algorithms of concrete mixtures design, their

accuracy and speed.

In technological practice method of designing concrete mixtures with the

required compressive strength is the most common. Many properties of concrete

are simply linked with compressive strength such as flexural and tensile strength,

resistance to abrasion, etc. However, dependence between strength and frostresistance or strength and creep, etc. is not always straight proportional. Their

calculated determination must be based on the complex of the special

quantitative dependences.

Most developed and realized in practice there are 2-factor tasks, it means that

the given properties of concrete are compressive strength (R

) and

cmp

consistency of the mix (Slump or Vebe).

128

If there is a necessity in normalization of some other technical properties of

concrete, except for compressive strength, the problem of concrete mixtures

design becomes essentially complicated.

At designing mixtures of various and in particular special kinds of concrete

(hydrotechnical, road, etc.) there are multi-factors tasks. They can be divided

into three subgroups:

1With the normalized parameters unequivocally connected with

compressive strength of concrete;

2-With the normalized parameters uncertainly connected with compressive

strength of concrete;

3 - With the normalized parameters which have been not connected with

compressive strength.

For example, tasks with various given parameters of strength of concrete

belong to the first subgroup. At calculation of compositions of such concrete

mixture the defining parameter from given properties of the concrete and its

corresponding compressive strength are determined and established

minimally possible cement-water ratio (C/W) which providing all set of

properties.

129

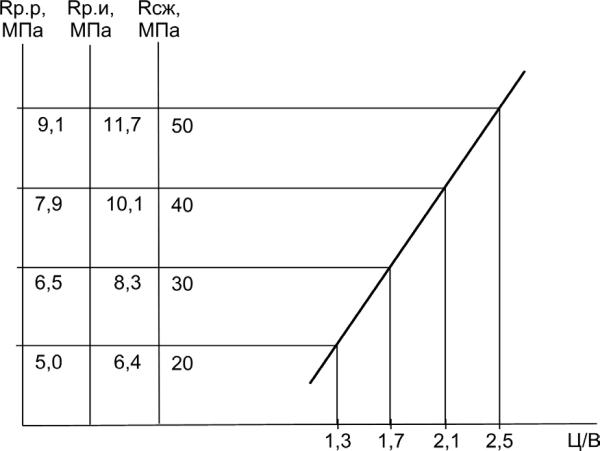

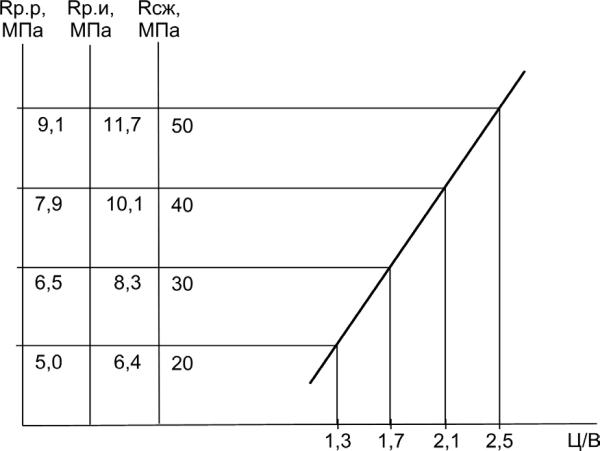

Rspl,

Rfl,

Rcmp,

MPa MPa MPa

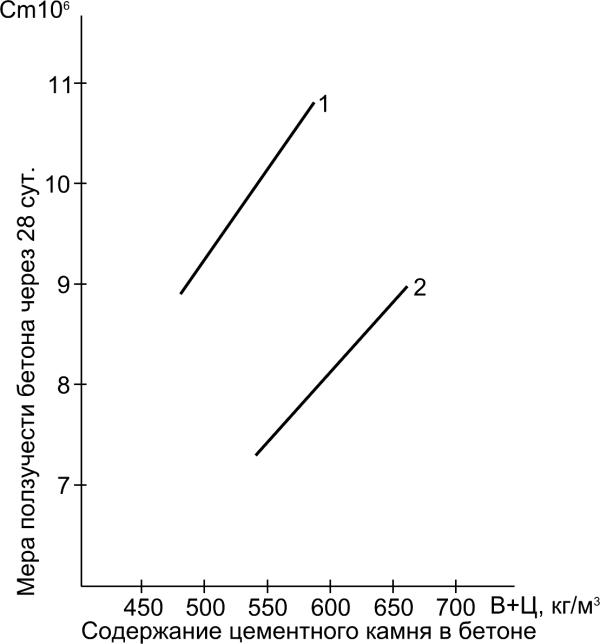

For example, from Fig.

7.1 follows, that if are

normalized: compressive

strength R

≥ 20 MPa,

cmp

flexural strength R ≥ 8,3

fl

MPa and splitting tensile

strength R

≥ 7,9 МПа,

spl

that, obviously, the

defining parameter is Rspl

and necessary cementwater ratio providing all

C/W

three parameters of

Fig. 7.1. Effect of cement-water ratio (C/W) on the

properties, is equal 2.1.

compressive strength (Rcmp), flexural strength (Rfl)

and splitting tensile strength (Rspl)

130

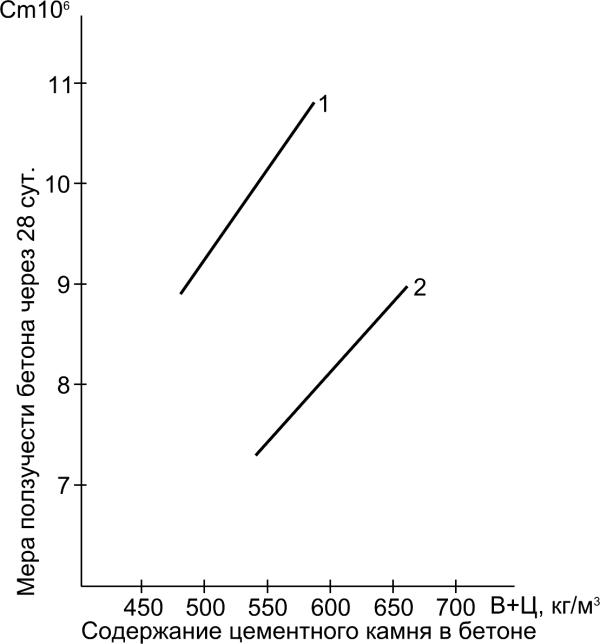

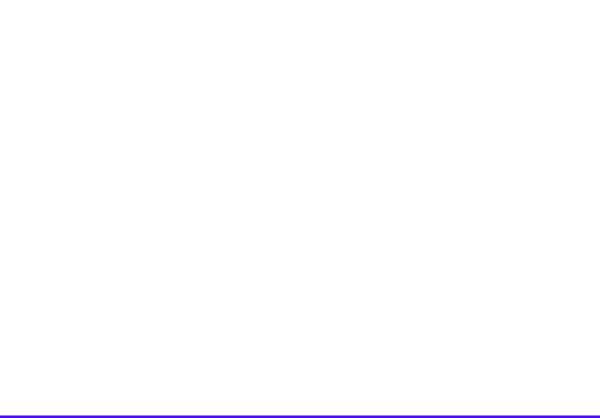

Normalized parameters in tasks of

the second subgroup of designing

concrete mixtures alongside with

6

compressive strength can be

10 m

creep, frost resistance, heat

generation, etc.

ys, Ca d8

at 2

Fig. 7.2 shows the example of

ep

relationship between creep and

of cre

quantity of the cement stone in

ue

concrete at constant

Val

compressive strength. At

constant water-cement ratio and

therefore concrete strength,

Quantity of cement stone in concrete, kg/m3

concrete creep can essentially

Fig. 7.2. Effect of quantity of the cement stone in concrete

differ depending on quantity of

on the value of creep:

1 – Compressive strength of concrete = 20 MPa;

the cement stone in concrete.

2 – Compressive strength of concrete = 30 MPa

131

For the tasks of concrete mixtures design of the third subgroup (for example,

light concrete) water-cement ratio is not a determinative factor, providing the

complex of the normalized properties. For such tasks is necessary to find

other, substantial for all normalized properties factor. Determination of

necessary value of this factor becomes the main task of concrete mixtures

design.

7.2. Selection of raw materials and admixtures

Task of a choice of initial materials is the technical and economic problem

defining efficiency of designed concrete mixtures and an opportunity of

achievement of demanded properties of concrete.

The basic technical parameters at a choice of a kind of cement are:

chemical composition, strength, rate of hardening, normal consistency and

fineness.

For an estimation of efficiency of use of cement the relative parameters

describing the quantity of cement or its cost on unit of strength and also

ratio between strength of concrete and the quantity of cement are offered.

132

Active mineral admixtures (pozzolans) are added directly in concrete mixes

and widely applied to economy of cement and their most power-intensive

component - cement clinker.

"Cementing efficiency" or amount of cement saved at adding active mineral

admixtures depends on many factors characterizing their composition,

structure, fineness, terms of hardening, age of concrete, etc.

The characteristic feature of a modern concrete technology is wide

application of chemical admixtures for achievement of necessary concrete

properties, declines of expense of financial and power resources at

making concrete and at its application for constructions.

Expenses for the admixture (E ) at production of concrete can be

xa

calculated as follows:

Ex = C A + Ex adt , (7

.1)

a

a

a

Where C - cost of the admixture per 1 m3 of concrete including necessary

a

transport costs; A - the specific amount of the admixture;

adt

Ex

- the specific costs connected with additional processing of the

a

admixture, its storage, batching, change of the composition of

concrete mixture, etc.

133

For manufacturers of concrete (concrete mix, products and structures) is

important to distinguish the economic effect provided by the admixture due to

economy of other resources during manufacture and effect reached at concrete

application.

Expenses on admixture (E ) at the production of concrete mix are justified, if

xa

the following condition is executed:

Ex < Ex + Ex − Ex ' − Ex '

(7.2)