,

.3)

Where A-coefficient, specified in Table 7.1 depending on the different

factors; R – strength of cement at 28 days, MPa; R

– compressive

c

cmp

strength of concrete at 28 days, MPa.

Additional possibilities are opened at the use in the formula of strength in

place of ordinary multiplicative coefficient pA.

Equation of multiplicative coefficient pA can be presented as follows:

рА = А А1…Аi…Аn, (7.4)

Where А is a coefficient, taking into account additional influence on the

i

value of strength of i-factor (i=1…n).

Ordinary technological information allows to take into account in the

multiplicative coefficient pA to 2 or 3 additional coefficients А .i

135

Table 7.1

Recommended values of coefficient A (from V.Sizov)

Contents of harmful

Value of coefficient A for concrete made

Kind of

substances (clay, silt, soft

with the use of

aggregates

particles) in crushed stone

(gravel) and sand, %

Crushed

Gravel

Gravel river

stone

mountain

and marine

Crushed stone

0

(gravel)

0.64

0.6

0.57

Sand 0

Crushed stone

0

(gravel)

0.61

0.56

0.53

Sand

3

Crushed stone

1

(gravel)

0.58

0.53

0.5

Sand 3

Crushed stone

2

(gravel)

0.55

0.5

0.47

Sand 3

Crushed stone

2

(gravel)

0.52

0.47

0.44

Sand

5

136

Additional possibilities for expansion of range of the decided tasks of

designing concrete mixtures are possible at the use of the “modified cementwater ratio (C/W)

”:

mod

C + К

D

(C / W )

c.e

=

, (7.5)

mod

W + Vair

Where К

- coefficient of "cementing efficiency" of mineral admixtures, that

c.e

is content of cement in kg, commutable by 1 kg of mineral admixture: D content of mineral admixture, kg/m3; C and W – accordingly contents of

cement and water, kg/m3; V - volume of the entrained air, liters per m3.

air

In this case, formula (7.3) can be presented as follows:

C + К D

R

= pAR

c.e

− 0.5

. (7.6)

cmp

c W + V

air

Where R – strength of cement at 28 days, MPa; R

– compressive

c

cmp

strength of concrete at 28 days, MPa.

137

The coefficient of “cementing efficiency” can be easily defined from

experimental data for the concretes with identical strength by the following:

C − C

K

1

2

=

, (7.7)

c.e

D

Where C - content of cement in the concrete without mineral admixture; C

1

2

- content of cement in the concrete with mineral admixture; D - amount of

mineral admixture.

Application of the “modified cement-water ratio” is rational and useful in

particular for the concrete mixtures design with the limited or small amount

of cement at adding of mineral admixtures.

Calculation of water content.

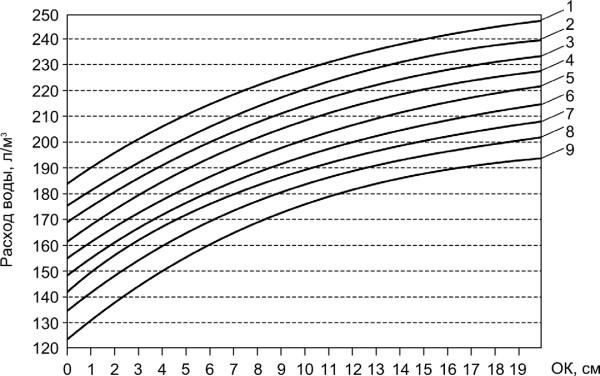

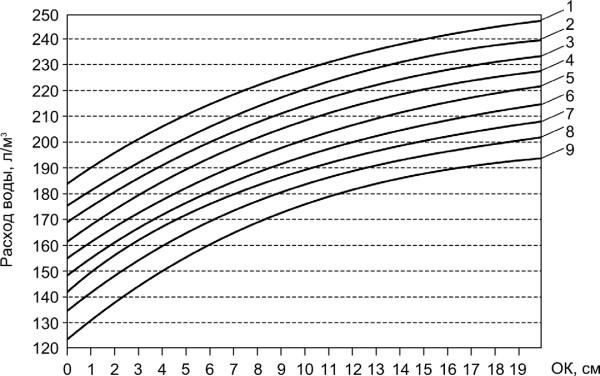

In practice of designing concrete mixtures the water content of concrete

mixtures is determined usually from empiric data by the graphs (Fig.7.3) or

tables which offer some base values of water content (kg/m3) depending on

the indexes of consistency of concrete mix and specified depending on the

features of initial materials. The rule of constancy of water content, in

accordance with which the water content for achievement necessary

consistency of concrete mix remains practically permanent in the certain

range of cement content or cement-water ratio, is widely used thus.

138

3

/mg, k

tera

of w

ount

Am

Slump,

cm

Fig. 7.3. Relationship between amount of water per cubic meter and slump

of concrete mix:

1 – Sand (Fineness modulus is equal 3); 2-9 – Granite crushed stone (Particle

sizes are 10, 15, 20, 30, 40, 60, 80 и 150 mm)

139

Calculation of aggregates content.

One of basic tasks of optimization of concrete mixtures is determination of

aggregates ratio, which provides the minimum amount of cement.

Widely applied in Russia and Ukraine the calculation-experimental methods

of designing concrete mixtures, use the coefficient (α) which characterizes

filling of voids between crushed stone (gravel) particles with cement-sand

pastes (mortar) (taking into account some stock of the paste for

achievement demanded consistency of the concrete mix) for determination

of quantities of sand and crushed stone (gravel).

Quantities of coarse and fine aggregates can be easily defined by decision

of system of two equations of material balance. The first equation

expresses equality of volume of the concrete mix to the sum of absolute

volumes of the initial components of concrete, the second - conformity of

volume of the cement - sandy paste (mortar) to volume of voids in the

coarse aggregates (taking into account some stock of the paste for

achievement demanded consistency of the concrete mix):

140

C

W

F

C

ag

ag

+

+

+

=1000

ρc ρw ρf ag

.

ρ ag

.

c

C

W

F

C

ag

+

+

= Р

ag

α

(7.