Measurement System and Process Performance Models

Measurement System Importance

To build strong High Maturity Practices at a quick time, the existing measurement system plays a vital role. They helps us to collect and use the relevant data with accuracy and precision. The following aspects in a measurement system are the key,

*Operational Definition for Measures/Metrics

*Type of Data and Unit of Measurement Details

*Linkage with B.O or QPPO or Process/Sub Process

*Source of Data

*Collection of Data

*Review/Validation of Data

*Frequency of collection and Submission

*Representation of Data – Charts, Plot, Table, etc

*Analysis Procedure

*Communication of Results to Stakeholders

*Measurement Data Storage and Retrieval

*Group Responsible & Stakeholder Matrix

*Trained Professionals to manage Measurement System

For every Measure the Purpose of collection and its intended usage to made clear, so that adequate support we can get from delivery teams and functions.

When the BO, QPPO and X factors are identified logically, sometimes the measurement data is available with you, sometimes not. When the data is available its important to check the existing data is collected in the expected manner and it has the unit which we want to have and no or less processing is required. If not, we may have to design the measurements quickly and start collecting it from the Projects and functions. Which means you may need to wait sometimes a month or two to collect the first level measures and build relationships.

The purpose at ML5 shifts from controlling by milestones to in process/phase controls, which means from lagging indicators to leading indicators. So we control the X factors and there by using their relationship with Y (Process, QPPOs) we understand the certainty/level of Meeting Y. So we build relationship models using the X factors and Y of past and/or current instance, which helps us to predict the Y.

Hence its important to have these X factor measures collected early in CMMI Ml5 implementation, that sets up the basis for Process performance model building and thereafter usage by Projects. Its also important to ensure there is Gauge R&R is done to ensure Repeatability and Reproducibility in measurement system, so that false alarms can be avoided and concentrate effort usefully.

A clear ML2 Measurement System is the need for strong ML4 and ML4 Maturity and institutionalization of ML5 Practices.

Modelling in CMMI

Process Performance Models in Information Technology Industry is pretty young concept even after many models and standards described its need from prediction and control point of view. Especially Capability Maturity Model Integrated call for it to assess an organization as Highly Matured Organization.

In CMMI Model, the Process Area ‘Organization Process Performance’ calls for useful Process Performance Model (PPM)s establishment (& calibration) and Quantitative Project Management and Organizational Performance Management process areas gets more benefit by using these models to predict or to understand the uncertainties , thereby helping in reducing risk by controlling relevant process/sub processes.

The PPM’s are built to predict the Quality and Process Performance Objectives and sometimes to Business Objectives (using integrated PPMs)

Modelling plays a vital role in CMMI in the name of Process Performance Models. In fact we have seen Organizations decide on the goals and immediately starts looking at what are their Process Performance Model. It’s also because of lack of options and clarity, considering in software the data points derived are smaller in nature and also because of process variation.

Considering it’s a growing filed and many wants to learn the techniques which can be applied in IT Industry, we have added the content in this chapter. At the end of the chapter you will be able to appreciate your learning on new Process Performance Models in IT Industry and work on few samples. Don’t forget to claim your free data set from us to try these models.

What are the Characteristics of a Good PPM?

One or more of the measureable attributes represent controllable inputs tied to a sub process to enable performance of ―what-if analyses for planning, dynamic re-planning, and problem resolution.

Process performance models include statistical, probabilistic and simulation based models that predict interim or final results by connecting past performance with future outcomes.

They model the variation of the factors, and provide insight into the expected range and variation of Predicted results.

A process performance model can be a collection of models that (when combined) meet the criteria of a process performance model.

The role of Simulation & Optimization

Simulation:

It’s an activity of studying the virtual behaviour of a system using the representative model / miniature by introducing expected variations in the model factors / attributes.

Simulation helps us to achieve confidence on the results or to understand the uncertainty levels

Optimization:

In the context of Modelling, Optimization is a technique in which the model outcome can be maximized/minimized or targeted by introducing variations in the factors (with/without constraints) and using relevant Decision rules. The Values of factors for which the outcome meets the possible expected values are used as target for planning/composing process/sub process. This helps us to plan for success.

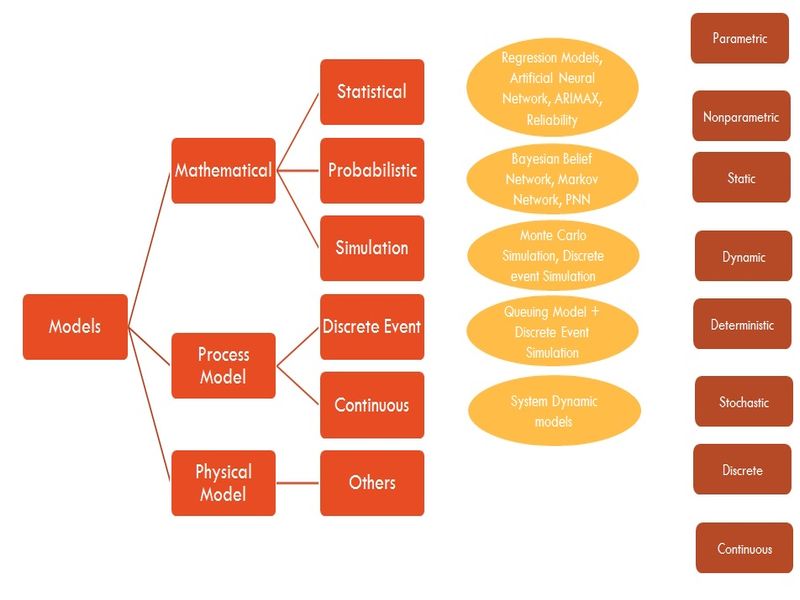

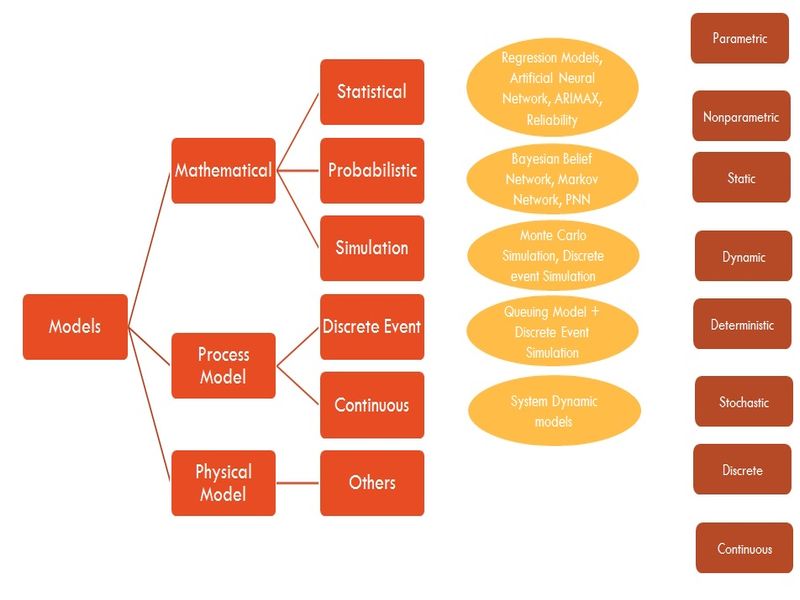

Types of Models - Definitions

Physical Modelling:

The Physical state of a system is represented using the scaled dimensions with/without similar components. As part of Applied Physics we could see such models coming up often. Example: Prototype of a bridge, a Satellite map, etc

Mathematical Modelling:

With the help of data the attributes of interest are used to form the representation of a system. Often these models are used when people involved largely in making the outcome or the outcome is not possible to be replicated in laboratory. Example: Productivity model, Storm Prediction, Stock market prediction, etc

Process Modelling:

The Entire flow of Process with factors and conditions are modelled. Often these models are useful in understanding the bottlenecks in the process / system and to correct. Ex: Airport queue prediction, Supply chain prediction, etc

Tree of Models

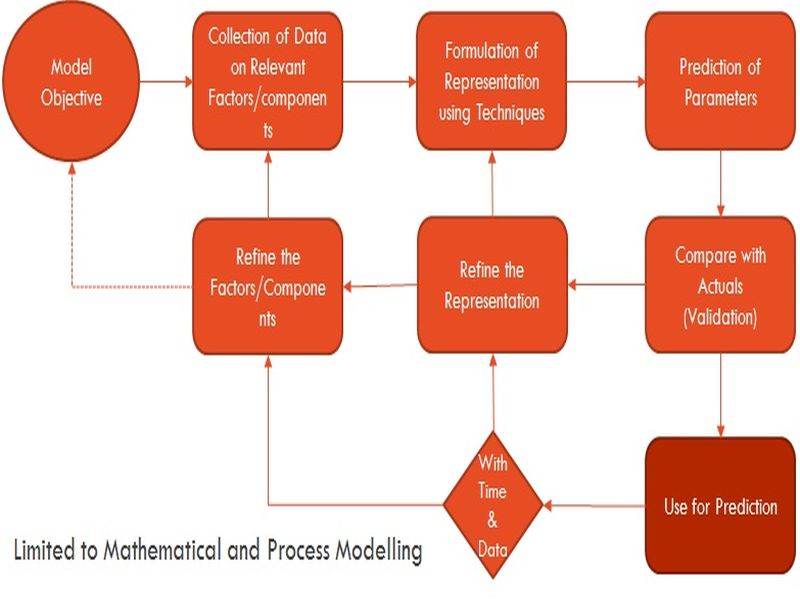

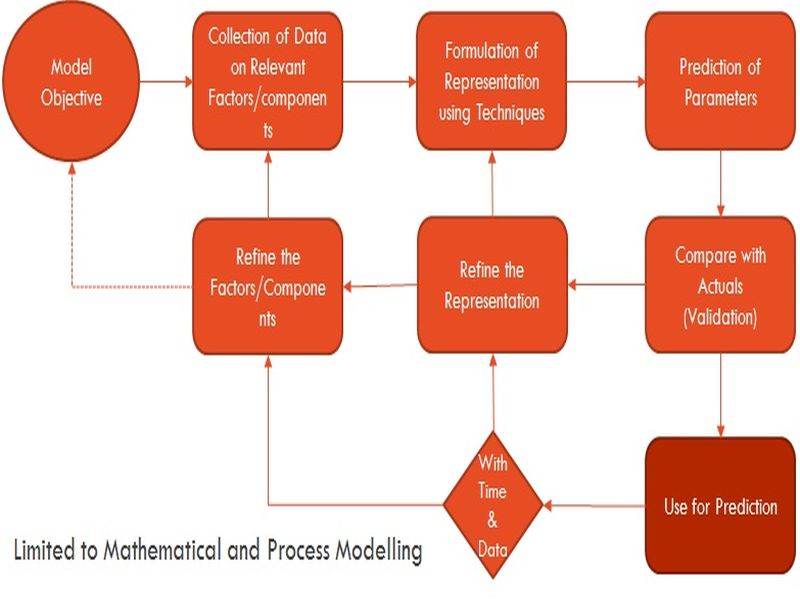

Process of Modelling

Modelling under our purview

We will see the following models in this chapter

Regression Based Models

Bayesian Belief Networks

Neural Networks

Fuzzy Logic

Reliability Modelling

Process Modelling (Discrete Event Simulation)

Monte Carlo Simulation