56555-287-3, New Orleans, January 2005, SCS.

Norman S. Nise, (2000). Control Systems Engineering , John Wiley & Sons, ISBN:970-24-0254-9,

United States of America.

Peter Gawthrop, Lorcan Smith (1996)., Metamodelling , Prentice-Hall,ISBN:0-13-489824-9,

Great Britain.

P.E. Wellstead, (1979). Physical System Modelling , Academic Press, ISBN:0-12-744380-0

London.

P. J. Gawthrop and D. Palmer, (2003). A bicausal bond graph representation of operational

amplifiers", Proceedings of the Institution of Mechanical Engineers Part I: Journal

Systems and Control Engineering , Vol. 217

Ramakant A. Gayakward, (2000), Op-amps and Linear Integrated Circuit , Prentice Hall,

ISBN:0-13-280868-4, United States of America.

314

New Approaches in Automation and Robotics

Thomas L. Floyd and David Buchla, (1999), Basic Operational Amplifiers and Linear Integrated

Circuits , Prentice-Hall, ISBN:0-13-082987-0, United States of America.

William D. Stanley, (1994). Operational Amplifiers with Linear Integrated Circuits , Maxwell

Macmillan International

20-Sim, Controllab Products (2007) B. V., 20-Sim, http://www.20sim.com/ product/20sim.html

17

Hypermobile Robots

Grzegorz Granosik

Technical University of Lodz

Poland

1. Introduction

Hypermobile robots belong to the group of hyper-redundant articulated mobile robots. This

group can be further divided based on two characteristic features: the way the forward

motion of the robot is generated and the activity of its joints, as shown in Table 1.

Propulsion→

External propulsion elements:

Movement is generated by

Joints↓

legs, wheels, tracks

undulation

Hypermobile robots:

• Koryu-I and Koryu-II (Hirose, 1993)

• Snake 2 (Klaassen and Paap, 1999)

Snake-like robots:

• Soryu (Takayama and Hirose, 2000)

• Active Cord Mechanism whole

• Millibot Train (Brown et al., 2002)

family of robots (Hirose, 1993)

• Moira (Osuka & Kitajima, 2003)

• Slim Slime Robot (Ohno &

Active joints • Pipeline Explorer (Schempf et al., 2003) Hirose, 2000)

• Omnis family (Granosik et al., 2005)

• Snake robots by Dr. Gavin

• MAKRO plus (Streich & Adria, 2004)

Miller (snakerobots.com)

• KOHGA (Kamegawa et al., 2004)

• Perambulator-II (Ye et al., 2007)

• JL-I (Zhang et al., 2006)

• Wheeeler (Pytasz & Granosik, 2006)

Active wheels – passive joints robots:

Passive joints •

Genbu 3 ( Kimura & Hirose, 2002)

Table 1. Articulated mobile robots

Articulated robots can also be divided in other way, as suggested by Robinson and Davies

(1999), into three groups: discrete, serpentine and continuum. Most robots are discrete

mechanisms constructed from series of rigid links interconnected by discrete joints. In case

of robotic manipulators joints are usually one degree of freedom (DOF) but in case of

articulated mobile robots we can find 2 and 3 DOF joints more often. Multi degree of

freedom joints create naturally spatial devices, which can bend in any direction.

Serpentine robots also utilize discrete joints but combine very short rigid links with a large

density of joints. This creates highly mobile mechanisms producing smooth curves, similar

to snake. And therefore representatives of this group of robots are also called snake-like

316

New Approaches in Automation and Robotics

robots, as shown in Fig. 1. Some of the hypermobile robots feature very short links relative

to the cross section size and also belong to this group.

Fig. 1. Active Cord Mechanism (left) reproduced from (Hirose, 1993), ACM-R3 reproduced

from (Mori & Hirose, 2002)

Continuum robots do not contain rigid links and identifiable rotational joints. Instead the

structures bend continuously along their length via elastic deformation and produce motion

through the generation of smooth curves, similar to the tentacles. The good example of

continuum mobile robots is Slim Slime Robot (see Fig. 2).

Fig. 2. Slim Slime Robot reproduced from (Ohno & Hirose, 2000)

In the next part of this paper we present a few major projects of hypermobile robots from

around the world, focusing on comparison of design concepts, main features, performance,

teleoperation or automated operation techniques. Finally, we present our own hypermobile

robot Wheeeler showing design concept, model, simulation results, construction and tests of

prototype. In conclusion we summarize this digest with a table showing basic properties of

presented robots. We also show advantages and disadvantages of our design and future

plans. We hope to show some general ideas on designing, constructing and control of such

complex devices as hypermobile robots with many redundant degrees of freedom.

2. History of hypermobile robots

One of the scenarios where hypermobile robots could play the main role is search and

rescue. The intensified work in this field was related to the large catastrophes happened in

different countries: Kobe earthquake, terrorist attacks on World Trade Center in New York

and bomb attacks on trains in London and Madrid. In this application robots are intended

to slither into the debris and gather visual information about possible victims. Therefore, it

is expected that robot fits small openings, can travel in the rummage of structured

Hypermobile Robots

317

environment and overcome obstacles. The other important application for hypermobile

robots are inspection tasks in sewage systems, gas pipes or venting systems.

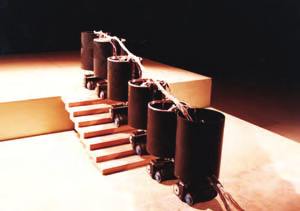

The first practical realization of a hypermobile robot, called Koryu or KR-I, was introduced

by Hirose and Morishima (1990) and later improved with version KR-II (Hirose et al., 1991),

as shown in Fig. 3. KR-II was developed with premise that it will be applied as a mobile

robot for atomic reactor. It was also considered to be used as a substitution of fireman in

rescuing activity: patrolling, gas detection, inspection and to rescue a person. This first

hypermobile robot was large and heavy, weighing in at 350 kg. The robot comprised of

multiple vertical cylindrical segments on powered wheels (tracks in KR-I) that gave the

mechanism a train-like appearance. Vertical joint actuators allow a segment to lift its

neighbors up, in order to negotiate steps or span gaps. Each segment of KR-II is equipped

with single wheel, arranged so that the unit with wheel on the right side will come after a

unit with the wheel on the left side. This single wheel design may seem unbalanced at the

first glance but its stability is secured as the segments are linked. Especially, if the vehicle

have the zigzag configuration. Moreover, this single wheel design has other advantages:

•

as each segment is connected to the body by 2DOF joint it may be seen as having sliding

active suspension,

•

the adaptability to the steep inclination during traversing can be realized by shifting all

wheels on one side up or down in vertical direction,

•

in addition, this design doesn’t require the differential mechanism of the double wheel

structure to permit different speed rotation on curves.

Fig. 3. The Koryu-I (KR-I) robot on the left and KR-II on the right (reproduced from

http://www-robot.mes.titech.ac.jp)

These robots inherited all capabilities of earlier developed snake-like robots:

•

They can go on irregular terrain with sharp rises and falls and travel a path that winds

tightly,

•

They can cross over crevasses by holding its body length rigid to act as a bridge,

•

In marshy and sandy terrain, it can move by distributing force along its entire body

length.

Additional active crawlers or wheels mounted on each segment give further advantages:

•

High speed motion – direct propulsion is more effective then undulation,

•

High load capacity – simple driving system gives large weight of load to its own weight

ratio,

•

Good portability by its unitized structure,

•

High reliability, because it is made redundant – broken segments can be easily replaced

and special segments could be added depending on mission,

318

New Approaches in Automation and Robotics

•

Versatility of the body motion – Koryu can be used not only for “locomotion”, but also

for “manipulation” – as claim authors (Hirose & Morishima, 1993).

For motion control of the robot with several wheels touching ground the force sensors to

detect reaction force were indispensable. To solve the problem, special construction of

optical based force sensing was introduced. Such sensors were mounted in both vertical and

horizontal axes to control robot among obstacles and on uneven terrain.

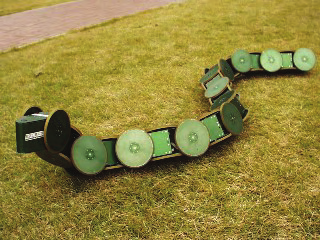

More recently, Klaassen and Paap (1999) at the German National Research Center for

Information Technology (GMD) developed the Snake2 vehicle, which contains six active

segments and a head, as shown in Fig. 4. Each round segment has an array of 12 electrically

driven wheels evenly spaced around its periphery. These wheels provide propulsion

regardless of the vehicle’s roll angle. Segments are interconnected by universal joints

actuated by three additional electric motors through strings. Snake2 is an example of a robot

that is inspired by the physiological structure of snakes where wheels replace tiny scales

observed on the bodies of some real snakes. Snake2 is equipped with six infrared distance

sensors, three torque sensors, one tilt sensor, two angle sensors in every segment, and a

video camera in the head segment. Snake2 was specifically designed for the inspection of

sewage pipes. With segments measuring 18cm in diameter and 13.5cm length Snake2

belongs to the serpentine group.

Fig. 4. Snake2 developed at the GMD

This robot was a successor of the GMD-Snake, typical continuum spatial robot built in a

very elastic way to allow flexible bending of the parts (Worst & Linnemann, 1996).

However, Authors observed an uncontrolled torsion effect which occurred when the snake

lifted some of its parts (to climb on a step). This disadvantage forced them to construct the

next generation in a more rigid way using universal joints but leaving rope-based driving

system. GMD snakes were the first articulated robots employing CAN bus communication

in the distributed control system.

Another hypermobile robot designed for sewer inspection was developed by Scholl et al.

(2000) at the Forschungszentrum Informatik (FZI) in Germany. Its segments use only two

wheels but the actuated 3-DOF joints allow full control over each segment’s spatial

orientation. The robot is able to negotiate tight 90° angled pipes and climb over 35 cm high

obstacles. One segment and its joint are about 20 cm long each. The sensor suite of this robot

is similar to that of Snake2. The development of sewer inspection robots was continued in

the joint project MAKRO plus (Streich & Adria, 2004).

MAKRO plus , is an autonomous service robot that can be used for a whole range of specific

duties within a canalization system. Robot has symmetrical construction with head

segments on both ends. These segments contain camera, structured light source and

ultrasound sensor. Four-level hierarchical control system is proposed to autonomously

Hypermobile Robots

319

drive robot inside sewage pipes. The robot’s mission is specified by human operator who

determines entry and recovery points and downloads map of all pipes and manholes in the

inspection area. Then the planning algorithm generates the sequence of actions, which are

executed by action controller. In case of obstacle detection, blockage or malfunction, planner

automatically finds new set of actions. Robot can be equipped in specialized modules. A

chemistry module measures pH levels, conductivity, O2 and temperature of waste water

with the help of a sample probe. When required, samples can be retrieved by the robot for

further analysis in a laboratory. A navigation module which can record speed and three

fiber optic gyroscopes measure the gradient and direction of the pipes in a canalization

system. This helps to support the success of the mission and it is also provides a useful and

accurate update for the land registry records, as informs INSPECTOR SYSTEMS Rainer

Hitzel GmbH.

Fig. 5. MAKRO plus robot for sewer inspection (reproduced from Streich & Adria, 2004)

While wheeled serpentine robots can work well in smooth-walled pipes, more rugged

terrain requires tracked propulsion. To this effect Takayama and Hirose (2000) developed

the Souryu-I crawler, which consists of three segments, as shown in Fig. 6.

Fig. 6. Souryu from Hirose Lab (reproduced from http://www-robot.mes.titech.ac.jp)

Each segment is driven by a pair of tracks, which, in turn, are all powered simultaneously

by a single motor, located in the center segment. Torque is provided to the two distal

segments through a rotary shaft and universal joints. Each distal segment is connected to the

center segment by a special 2-DOF joint mechanism, which is actuated by two lead screws

driven by two electric motors. The robot can move forward and backward, and it can

change the orientation of the two distal segments in yaw and pitch symmetrically to the

center segment. Coordinated rotations of these joints can generate roll over motion of the

robot. One interesting feature is the ability of this robot to adapt to irregular terrain because

of the elasticity of its joints. This elasticity is provided by springs and cannot be actively

controlled. The newest incarnation – Souryu-II – is designed to separate three bodies easily

320

New Approaches in Automation and Robotics

so as to make it portable and to make it possible to add segments with special functions.

Robot is equipped with camera and batteries, and can be remotely controlled.

A different concept using unpowered joints was introduced by Kimura and Hirose (2002) at

the Tokyo Institute of Technology. That robot, called Genbu (see Fig. 7), is probably the only

serpentine robot with unpowered joints. The stability of the robot and its high mobility on

rough terrain are preserved by large-diameter wheels (220 mm). The control system

employs position and torque feedback sensors for the passive but rigid joints. Springs are

used to protect the electric motors from impact, although the stiffness of the springs cannot

be controlled during operation. Robot was intended mainly for two applications: as a fire-

fighting robot to pull a fire hose or as a planetary rover.

Fig. 7. Robot Genbu representing group of active wheels – passive joints robots

Another robot incorporating a combination of passive and active joints as well as

independently driven and coupled segments is KOHGA developed by Kamegawa et al.

(2004) and shown in Fig. 8. Robot comprises 8 segments of different structure and function:

two distal segments have CCD cameras mounted but have no propulsion means, the second

units have the right and left crawlers which are driven co-accessibly, the other segments also

have the right and left crawlers but independently driven. There is also a variety of joints

implemented in this design:

•

Two 2DOF joints driven by simple RC servos to control position of heads with cameras,

•

Two 2DOF joints with powerful DC motors and linkages to rise two segments on either

end, this improves the capability of climbing over obstacles,

•

Three 3DOF passive joints interconnecting main driving units, their function is to adjust

robot’s shape to the environment and efficiently transmit crawler force, they are passive

for light weight and simplicity.

Fig. 8. Robot KOHGA and KOHGA 2 (in a few configurations) from Matsuno Lab. at the

University of Electro-Communications

Hypermobile Robots

321

This robot implements a smart design feature: besides a camera in the front segment, there

is a second camera in the tail section that can be pointed forward, in the way a scorpion

points its tail forward and over-head. This “tail-view” greatly helps teleoperating the robot.

Operator is using SONY gamepad as user input and monitor with specially organized video

outputs. Authors proposed also algorithm (based on robot kinematics only) to calculate

speed of tracks and rotation of joints to realize follow-the-leader control of robot.

KOHGA with its passive joints has an important problem that obstacles can be caught to the

joints and then the robot is stuck. To solve this problem, the new reconfigurable version of

KOHGA 2 was developed (Miyanaka et al. 2007). The unit structure consists of the crawler-

arm-units, the joint-units, the terminal-units and the connecting parts. It can work as a self-

contained module or can be connected with other units creating multi-segmented vehicle.

Moreover, it can take various forms by the swing motion of the crawler-arms, and avoid

various stuck conditions. These crawler-arms can be mounted in two ways: the rotational

axes of right and left crawler-arms are alternately attached to the vehicle (called the non-

coaxial type), or these axes are attached to the same end of the vehicle (called the coaxial

type). Authors have considered several robot configurations, in different stuck-prone

conditions, in both high- and low-ceiling environments. They concluded that (1) the ability

of the stuck avoidance declines if the number of the connected vehicles is small because the

performance of vertical step climbing falls off and (2) that the coaxial type robot is more

effective to the stuck avoidance than the non-coaxial type robot.

The concept of joining several small robots into a train to overcome larger obstacles was

used by researchers from Carnegie Mellon University in their Millibot Train (Brown et al.,

2002). This robot consists of seven electrically driven, very compact segments. The diameter

of the track sprockets is larger than the height of each segment, which allows the robot to

drive upside-down. Segments are connected by couplers for active connection and

disconnection, but the joints have only one DOF. Each joint is actuated by an electric motor

with a high-ratio harmonic gear and slip clutch. It provides sufficient torque to lift up the

three front segments. The robot has been demonstrated to climb up a regular staircase and

even higher steps. However, with only one DOF in each joint the vehicle is kinematically

limited.

A serpentine robot that uses tracks for propulsion and pneumatics for joint actuation is

MOIRA shown in Fig. 9 (Osuka & Kitajima, 2003). MOIRA comprises four segments, and

Fig. 9. Robot Moira from Osuka Lab.

each segment has two longitudinal tracks on each of its four sides, for a total of eight tracks

per segment. All tracks are driven from a single motor through the system of 4 bevel and 4

spiral gears and therefore they move in the same direction. With tracks on each side robot is

322

New Approaches in Automation and Robotics

insensitive for rollovers and with additionally cone shaped distal segments robot can dig

into the debris with obstacles touching it from all sides. The 2-DOF joints between segments

are actuated by pneumatic cylinders. Although with pneumatic cylinders MOIRA can lift up

its segments high enough to overcome obstacles, it can also decrease stiffness of actuators to

nicely conform to the ground, but we think that with very long joints this design is prone to

getting stuck on some narrow obstacles. Robot is controlled from the specially designed

control box containing 3 joysticks and several switches. There is also view from nose CCD

camera transmitted via USB.

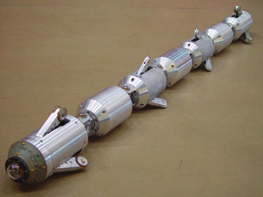

The newest construction from NREC (National Robotics Engineering Center) is Pipeline

Explorer – robot designed and built for inspection of live gas pipelines (Schempf et al.,

2003). This robot, shown in Fig. 10, has a symmetric architecture. A seven-element

articulated body design houses a mirror-image arrangement of locomotor (camera)

modules, battery carrying modules, and support modules, with a computing and electronics

module in the middle. The robot’s computer and electronics are protected in purged and

pressurized housings. Segments are connected with articulated joints: the locomotor

modules are connected to their neighbors with pitch-roll joints, while the others – via pitch-

only joints. These specially designed joints allow orientation of the robot within the pipe, in

any direction needed.

Fig. 10. Pipeline Explorer from NREC (reproduced from

http://www.rec.ri.cmu.edu/projects/explorer)

The locomotor module houses a mini fish-eye camera, along with its lens and lighting

elements. The camera has a 190-degree field of view and provides high-resolution color

images of the pipe’s interior. The locomotor module also houses dual drive actuators

designed to allow for the deployment and retraction of three legs equipped with custom-

molded driving wheels. The robot can sustain speeds of up to four inches per second. It is

fully untethered (battery-powered, wirelessly controlled) and can be used in explosive

underground natural gas distribution pipelines. Construction of robot naturally limits its

application to pipes of certain diameters.

From 2002 to 2005 researchers from the Mobile Robotics Lab at the University of Michigan

introduced the whole family of hypermobile robots called Omnis, shown in Fig. 11. In the

OmniPede, the first one, they introduced three innovative functional elements: (1)

propulsion elements (here: legs) evenly located around the perimeter of each segment; (2)

pneumatic power for joint actuation; and (3) a single so called “drive shaft spine” that

transfers mechanical power to all segments from a single drive motor (Long et al., 2002).

From the study of the OmniPede, and from the observed shortcomings of this legged

propulsion prototype, they derived important insights about the design of serpentine

Page 1 Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9 Page 10 Page 11 Page 12 Page 13 Page 14 Page 15 Page 16 Page 17 Page 18 Page 19 Page 20 Page 21 Page 22 Page 23 Page 24 Page 25 Page 26 Page 27