1

y 2 y 1 y 2 ⎤⎦ . (32)

⎣q⎦

The equations of motion (9) are available in symbolic form. Inserting the muscle force

characteristics, the internal muscle pressures as control inputs can be parameterized by the

flat outputs and their time derivatives

⎡ p

M 1 l(q, q, q, pM 1 ) ⎤

⎢ p

⎥

⎢

M r (q, q, q, pM )

1

1 ⎥

u =

= (

u q, q, q, pM 1, pM 2 )

⎢

. (33)

p

q q q

⎥

M 2 l( , , , pM 2 )

⎢

⎥

⎢ p

⎣

M 2 r (q, q, q, pM 2 )⎥⎦

In the following, three different nonlinear control approaches are employed to stabilize the

error dynamics of the outer control loop: flatness-based control, backstepping and sliding-

mode control (Khalil, 1996). For all these alternative designs, the differential flatness

property proves advantageous (Sira-Ramirez & Llanes-Santiago, 1995; Aschemann et. al.,

2007).

3.3 Flatness-based control

In the case of flatness-based control, the inverse dynamics is evaluated with the measured

crank angles and the corresponding angular velocities obtained by real differentiation

(Aschemann & Hofer, 2005). For the mean pressures, however, desired values are utilized.

The second derivatives of the crank angles, the angular accelerations, serve as stabilizing

inputs

T

u = ⎡ p

⎣ M 1 l pM 1 r pM 2 l pM 2 r ⎤ = (

u q, q, v

⎦

1 , v 2 , pM 1 d , pM 2 d ) . (34)

The inverse dynamics leads to a compensation of all nonlinearities. An asymptotic

stabilization is achieved by pole placement with Hurwitz-polynomials for the error

dynamics for each drive i = {1, 2}

Nonlinear Model-Based Control of a Parallel Robot Driven by Pneumatic Muscle Actuators

35

t

v

i = qid + α i 2 ⋅ ( qid − qi ) + α i 1 ⋅ ( qid − qi ) + α

∫ i 0 ⋅( qid − qi) dτ . (35)

0

3.4 Backstepping control

The first step of the backstepping control design (Khalil, 1996) involves the definition of the

tracking error variable for each drive i = {1, 2},

e

i 1 = qid − qi

⇒ ei 1 = qid − qi . (36)

Next, a first Lyapunov function Vi 1 is introduced

!

1

2

2

i

V 1( ei 1) = ei 1 > 0 ⇒

1

V ( ei 1) = ei 1 ⋅ ei 1 = ei 1 ⋅( qid − qi)=− c 1 ⋅ ei 1 (37) 2

and the expression for its time derivative is solved for the virtual control input

e

i 1 = qid − qi = c

− 1 ⋅ ei 1 ⇒ qi ≈ α iI( ei 1, qid) = qid + c 1 ⋅ ei 1 . (38) In the second step, the error variable ei 2 is defined in the following form

e

i 2 = α iI ( ei 1 , qid ) − qi = qid − qi + c 1 ⋅ ei 1

⇒ ei 1 = ei 2 − c 1 ⋅ ei 1 (39)

and its time derivative is computed

e

i 2 = qid − qi + c 1 ⋅ ei 1 = qid − qi + c 1 ⋅ ( ei 2 − c 1 ⋅ ei 1 ) . (40) Now, a second Lyapunov function Vi 2 is specified.

1

1

2

2

i

V 2( ei 1, ei 2) = ei 1 + ei 2 > 0 ⇒

i

V 2( ei 1, ei 2 ) = ei 1 ⋅ ei 1 + ei 2 ⋅ ei 2 (41)

2

2

The corresponding time derivative

!

2

2

2

i

V 2( ei 1, ei 2 ) = c

− 1 ⋅ ei 1 + ei 2 ⋅[ qid − vi + c 1 ⋅( ei 2 − c 1 ⋅ ei 1) + ei 1]=− c 1 ⋅ ei 1 − c 2 ⋅ ei 2 (42) can be made negative definite by choosing the stabilizing control input as follows

2

v = q = q + e 1 ⋅(1 − c 1 ) + e 2 ⋅( c 1 + c 2)

i

i

id

i

i

. (43)

Backstepping control design offers several advantages in comparison to flatness based

control. It becomes possible to avoid cancellations of useful, i.e. stabilizing nonlinearities.

Furthermore, different positive definite functions can be used at control design, e.g.

allowing for nonlinear damping.

3.5 Sliding-mode control

For sliding-mode control (Sira-Ramirez & Llanes-Santiago, 1995) the vector of tracking

errors is considered

⎡ q − q ⎤

id

i

z i = ⎢

. (44)

q

⎥

⎣

id − qi ⎦

36

New Approaches in Automation and Robotics

Based on this error vector z i , the following sliding surfaces si are defined for each drive

i = {1, 2}

si(z

i ) = qid − qi + β i 1 ⋅ ( qid − qi ) ⇒

si = qid − qi + β i 1 ⋅( qid − qi) , (45)

where β i 1 represents a positive gain. The convergence to the corresponding sliding surface is

achieved by introducing a discontinuous switching function in the time derivative of a

quadratic Lyapunov function

1

2

i

V ( si ) = si ⇒

i

V ( si) = si ⋅ si ≤ α

− i| si|= α

− i ⋅ si ⋅ sig (

n si) , (46)

2

with a properly chosen coefficient α i that dominates remaining model uncertainties. The

control design offers flexibility as regards the choice of the sliding surfaces and the reaching

laws. For the implementation, however, a smooth switching function is preferred to reduce

high frequency chattering. This results in the following stabilizing control law, which leads

to a real sliding mode within a boundary layer

s

i

v

i = qi = qid + β i 1 ⋅ ( qid − qi ) + α i ⋅ tanh(

) . (47)

ε

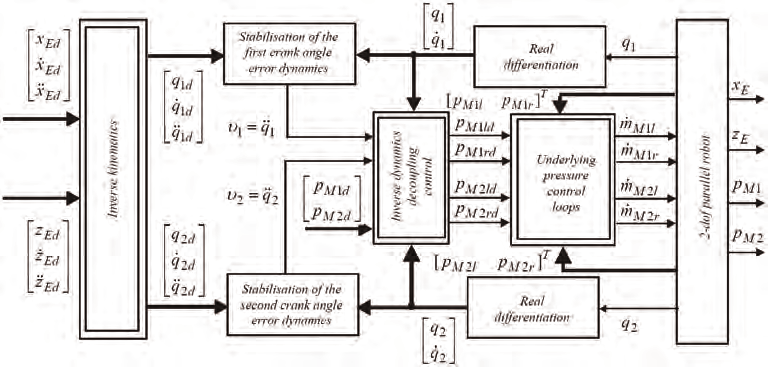

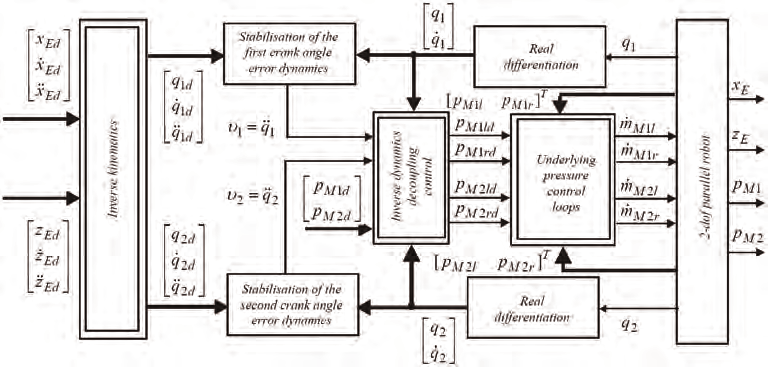

The implemented control structure is depicted in Fig. 8. The desired trajectories are

provided from an offline trajectory planning module that calculates time optimal trajec-

tories according to both state constraints and input constraints. This is achieved by proper

time-scaling of polynomial functions with free parameters as described in (Aschemann &

Hofer, 2005).

Fig. 8. Implementation of the decoupling control structure.

4. Disturbance observer design

The observer provides a vector ˆx2 of estimated disturbance torques that accounts for both

model uncertainties and nonlinear friction. The main idea consists in the extension of the

system state equations with the measurable state vector

Nonlinear Model-Based Control of a Parallel Robot Driven by Pneumatic Muscle Actuators

37

y x1 [q, q] T

=

=

(48)

by two integrators, which serve as disturbance models (Aschemann et. al., 2007)

y = f(y, ˆx , u), dim(y) = 4,

2

ˆx

(49)

= 0, dim(ˆ

2

x2 ) = 2.

The reduced-order disturbance observer according to (Friedland, 1996) is given by

z = Φ(y, ˆx , u), dim(z) =

2

2,

η

⎡ ˆ ⎤

ˆ

(50)

x = ⎢ 1

2

⎥ = H y + z ,

η

⎣ ˆ2 ⎦

where H denotes the observer gain matrix and z the observer state vector. The observer gain

matrix is chosen as follows

⎡ h

h

0

0 ⎤

11

11

H = ⎢

, (51)

0

0

h

⎥

⎣

22

h 22 ⎦

involving only two design parameters h 11 and h 22. Aiming at an asymptotically stable

observer dynamics

!

lim e = lim(x − ˆ

2

x2 )=0 , (52)

t→∞

t→∞

the observer gains are determined by pole placement based on a linearization using the

corresponding Jacobian (Friedland, 1996). In Fig. 9 a comparison of simulated disturbance

forces and the observed forces provided by the proposed disturbance observer is shown.

Here, the resulting tangential force at the pulley with radius r is depicted, which is related to

the disturbance torque according to F =ηˆ

iU

i / r . Obviously, the simulated disturbance

forces are reconstructed with high accuracy.

100

100

actual disturbance F2U

observed F2U

]

50

]

50

orce [N

orce [N

0

0

ial f

ial f

nt

nt

nge

nge

ta

-50

ta

-50

actual disturbance F1U

-100

observed F1U

-100

0

5

10

15

0

5

10

15

t [s]

t [s]

Fig. 9. Comparison of simulated disturbance force and observed disturbance force using the

reduced-order disturbance observer.

38

New Approaches in Automation and Robotics

5. Simulation results

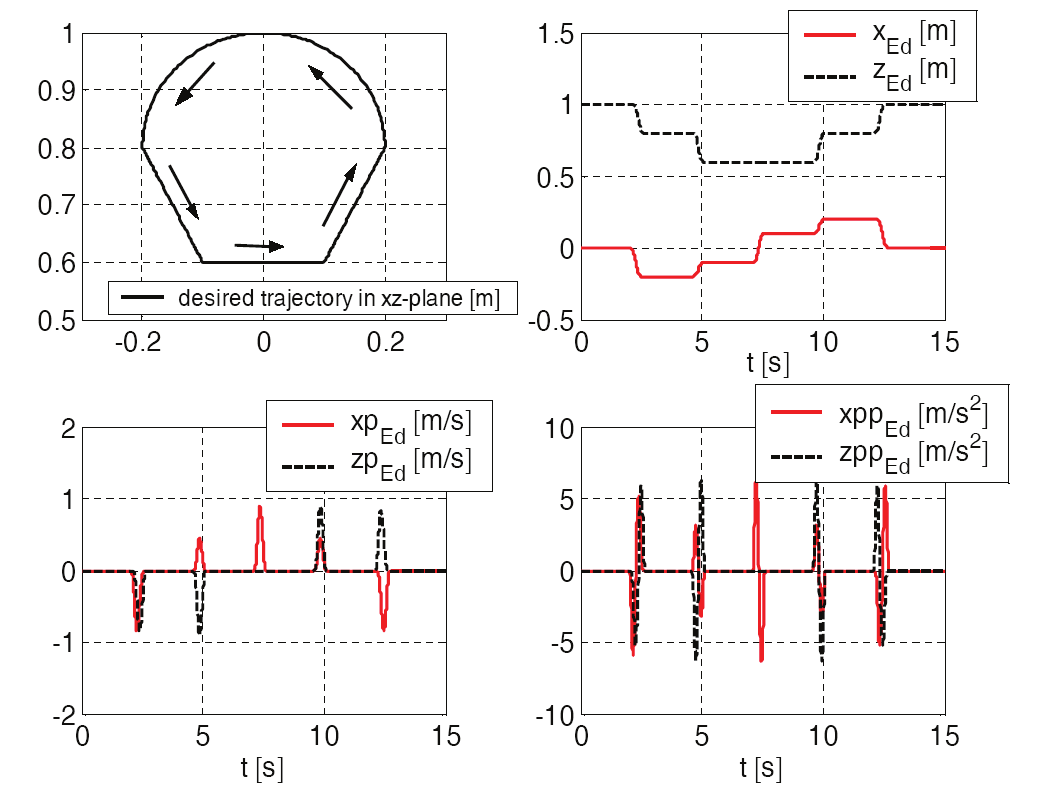

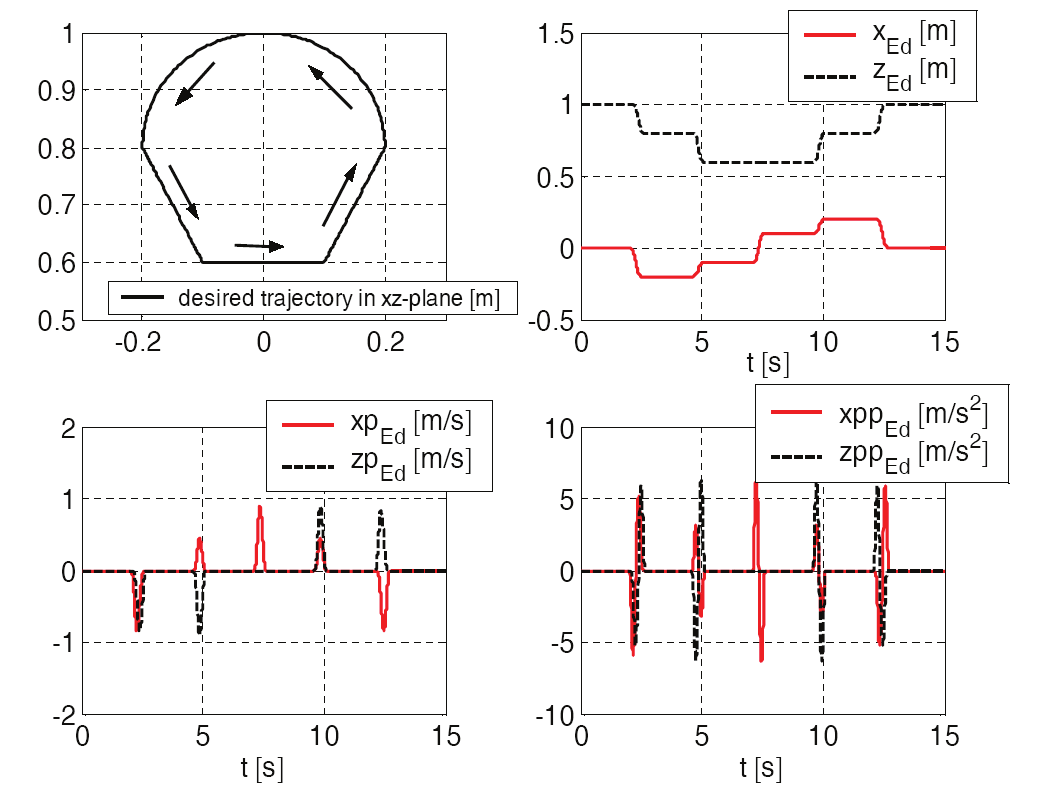

The efficiency of the proposed cascade control structure is investigated using the desired

trajectory shown in Fig. 10 with maximum velocities of approx. 0.9 m/s and maximum

accelerations of approx. 7 m/s2 for each axis.

The first part of the desired trajectory involves the motion on a quarter-circle with the radius

0.2 m from the starting point ( x = 0 m, z = 1 m) to the point ( x = −0.2 m, z = 0.8 m). The next three movements consist of straight lines: the second part comprises a diagonal movement

in the xz-plane to the point ( x = −0.1 m, z = 0.6 m), followed by a straight line motion in x-

direction to the point ( x = 0.1 m, z = 0.6 m). The fourth part is given by a diagonal movement

to the point ( x = 0.2 m, z = 0.8 m). The fifth part involves the return motion on a quarter-

circle to the starting point ( x = 0 m, z = 1 m).

Fig. 10. Desired trajectory in the workspace.

5 x 10-3

5 x 10-3

FB

BS

FB

0

]

]

SM

[m

0

[m

-5

e x

SM

e z

BS

-10

BS

-5

-15

0

5

10

15

0

5

10

15

t [s]

t [s]

Fig. 11. Comparison of the tracking errors in the workspace without disturbance observer.

Nonlinear Model-Based Control of a Parallel Robot Driven by Pneumatic Muscle Actuators

39

Fig. 11 shows a comparison of the resulting tracking errors in the workspace for flatness-

based control (FB), backstepping control (BS) and sliding-mode control (SM). Without

observer-based disturbance compensation, the best results are obtained using sliding-mode

control.

The efficiency of the observer based disturbance compensation is emphasized by Fig. 12. For

all considered control approaches a further improvement of tracking accuracy is achieved.

6. Conclusion

In this contribution, a cascaded trajectory control based on differential flatness is presented

for a parallel robot with two degrees of freedom driven by pneumatic muscles. The

modelling of this mechatronic system leads to a system of nonlinear differential equations of

eighth order. For the characteristics of the pneumatic muscles polynomials serve as good

approximations. The inner control loops of the cascade involve a flatness-based control of

the internal muscle pressure with high bandwidth. For the outer control loop three different

control approaches have been investigated leading to a decoupling of the crank angles and

the mean pressures as controlled variables. Simulation results emphasize the excellent

closed-loop performance with maximum position errors of approx. 1 mm during the

movements, vanishing steady-state position error and steady-state pressure error of less

than 0.03 bar, which have been confirmed by first experimental results at a prototype

system.

1 x 10-3

1.5 x 10-3

FB

1

0.5

]

SM

]

0.5

[m

0

[m

e x

e z

SM

0

-0.5

BS

FB

-0.5

BS

-1

-1

0

5

10

15

0

5

10

15

t [s]

t [s]

Fig. 12. Tracking errors in the workspace with observer-based disturbance compensation.

7. References

Aschemann H.; Hofer E.P. (2004). Flatness-Based Trajectory Control of a Pneumatically Driven

Carriage with Uncertainties, CD-ROM-Proc. of NOLCOS, pp. 239 – 244, Stuttgart,

September 2004

Aschemann H.; Hofer E.P. (2005). Flatness-Based Trajectory Planning and Control of a Parallel

Robot Actuated by Pneumatic Muscles, CD-ROM-Proc. of the ECCOMAS Thematic

Conference on Multibody Dynamics, Madrid, June 2005

Aschemann H.; Knestel, M.; Hofer E.P. (2007). Nonlinear Control Strategies for a Parallel Robot

Driven by Pneumatic Muscles, Proc. of 14th Int. Workshop on Dynamics and Control,

Moscow, June 2007, Nauka, Moscow

40

New Approaches in Automation and Robotics

Bindel, R.; Nitsche, R.; Rothfuß, R.; Zeitz, M. (1999). Flatness Based Control of Two Valve

Hydraulic Joint Actuator of a Large Manipulator. CD-ROM-Proc. of ECC, Karlsruhe,

1999

Carbonell P.; Jian Z.P.; Repperger D. (2001). Comparative Study of Three Nonlinear Control

Strategies for a Pneumatic Muscle Actuator, CD-Proc. of NOLCOS, Saint-Petersburg,

pp. 167 – 172, June 2001

Fliess M.; Levine J.; Martin P.; Rouchon P. (1995). Flatness and Defect of Nonlinear Systems:

Introductory Theory and Examples, Int. J. of Control, Vol. 61, No. 6, pp. 1327 – 1361

Friedland, B. (1996). Advanced Control System Design, Prentice-Hall

Göttert, M. (2004). Bahnregelung servopneumatischer Antriebe, Berichte aus der Steuerungs-

und Regelungstechnik (in German), Shaker

Khalil, H. K. (1996). Nonlinear Systems, 2nd. ed., Prentice-Hall

Sira-Ramirez H.; Llanes-Santiago O. (1995) Sliding Mode Control of Nonlinear Mechanical

Vibrations, J. of Dyn. Systems, Meas. and Control, Vol. 122, No. 12, pp. 674 – 678

3

Neural-Based Navigation Approach

for a Bi-Steerable Mobile Robot

Azouaoui Ouahiba, Ouadah Noureddine,

Aouana Salem and Chabi Djeffer

Centre de Développement des technologies Avancées (CDTA)

Algeria

1. Introduction

Recent developments in robotics have revealed a strong demand for autonomous out-door

vehicles capable of some degree of self-sufficiency. These vehicles have many applications in

a large variety of domains, from spatial exploration to handling material, and from military

tasks to people transportation (Azouaoui &Chohra, 1998; Hong et al., 2002; Kujawski, 1995;

Labakhua et al., 2006; Niegel, 1995; Schafer, 2005; Schilling & Jungius, 1995; Wagner, 2006).

Most mobile robot missions include autonomous navigation. Thus, vehicle designers search

to create dynamic systems able to navigate and achieve intelligent behaviors like human in

real dynamic environments where conditions are laborious.

In this context, these last few years small automated and non-pollutant vehicles are

developed to perform a public urban transportation task. T