N

VOLTAGE

CONTROLLED

G

CONVERTER

G

RESET

DRIVER

A

LOADING

N

N

VOLTAGE

CONTROLLED

V

(L298N)

L

CURRENT

CURRENT

DEVICE

REF

A

A

LOADING

S

SENSOR

L

L

CURRENT

CURRENT

DEVICE

HOME

(LEM MODULES)

CONTROLLED

S

S

SENSOR

SERVOMOTOR

TORQUE

VOLTAGE SENSORS

LOADING

r

m (t)

SENSOR

VOLTAGE u , u

SERVOMOTOR

TORQUE

F1

F2

DEVICE

r

m (t)

SENSOR

D.C.

DIC

CURRENT

CURRENT SENSORS

i , i

TAHO

TS

F1

F2

(LEM MODULES)

TORQUE

D.C.

DIC

TAHO

TS

SM

(LOAD)

SENSOR

SM

(LOAD)

n( )

t

n( )

t

n( )

t m(t)

OPTICAL

CLD

n( )

t

n( )

t

n( )

t m(t)

M

SENSE

ENCODER

SM

TS

M

(LOAD)

M

SENSE

E

OPTICAL

E

A B N

n( )

t

E

OPTICAL

A

TIRO

ENCODER

A

A

TIRO

(f) (f)

STEPPER

ENCODER

S

SENSE

S

SERVOMOTOR

S

U

A B N

U

U

A B N

R

(f) (f)

R

SD

SENSE

R

(f) (f)

E

E

DISCRIMINATOR

E

D

D

SENSE

CW

CCW SENSE

D

SENSE

SD

SD

DISCRIMINATOR

S

SPEED

DISCRIMINATOR

S

(4f)

(4f)

S

SPEED

I

I

2

2

I

2

CW

(4f)

G

POSITION

CW

G

SPEED

(4f)

G

SPEED

N

{

N

{

N

{

SPEED

POSITION

POSITION

CCW

A

CCW

A

A

SENSE

SENSE

L

SENSE

L

L

S

S

TORQUE

S

TORQUE

TORQUE

Fig. 1. Remote control architecture.

A user can have access to the process and run an experiment in real time using Intranet and

Internet. The user can design and implement different control structures for electrical drive

systems employing SCADA software facilities or, for a given control structure, he is able to

Networked Control Systems for Electrical Drives

75

implement and test PID control algorithms and tuning procedures. SCADA software

enables programmers to create distributed control applications having supervisory facilities

and a Human-Machine Interface (HMI). As SCADA software, Lookout is used for the direct

structure and LabVIEW for the hierarchical structure. All external signals start and arrive at

HMI/SCADA computer.

The laboratory architecture allows running experiments while interacting with instruments

and remote devices. The I/O remote devices permit data acquisition from sensors and

supplying control signals for actuators, using A/D and D/A converters.

The NCS architecture offers the possibility to remotely choose a predefined control structure

to handle the electrical drives system variables or to design a new control application, using

SCADA software facilities.

In the first case, using the remote control architecture the students have the possibility to

practice their theoretical knowledge of electrical drive systems control in an easy way due to

process access by a friendly user interface. The second opportunity offered to the students is

to design a new networked control architecture which allows creating a new HMI/SCADA

application to remotely control a process, using Lookout and, respectively, LabVIEW

facilities (Carari et al., 2003).

The software architecture can be split in two parts: one concerns the control of the physical

process – server side and the other relates to the user interface – client side. The server runs

on the Microsoft Windows NT platform and is based on Lookout for direct structure and,

respectively, LabVIEW environment for hierarchical structure.

The server application contains the HMI interface and fulfils the following functions:

•

implements the control strategies;

•

communicates with I/O devices through object drives;

•

records the signals in a database;

•

defines the alarms.

The client process contains a HMI interface, similar or not with those from server

application, and has the following characteristics:

•

allows modifying remotely the parameters defined by application server through a Web

site;

•

communicates with server application;

•

displays the alarms defined by the server application.

The remote control architecture is mainly intended for educational use and it is employed

for electrical drive control course. The aim is to allow students to put in practice their

knowledge of electrical drives and control theory in an easy way without restrictions due to

process availability through laboratory and project works. One of the main features is the

possibility of integrating in the control loop of the remote process the user-designed

controller. The interface for the controller synthesis is very friendly.

2.2 NCS in the direct structure

The NCS in the direct structure is composed of a computer of the Intranet, called

HMI/Lookout that achieves the local communications with the process using Ethernet

protocols. The remote electrical drive system, a D.C. brush servomotor, is connected with

the communication module (CM) able to transfer data from/to I/O device to/from

HMI/SCADA computer via a communication system. The communication module and I/O

devices are implemented with National Instruments modules, FP1600 (Ethernet) for

76

New Approaches in Automation and Robotics

communication and, respectively, Dual-Channel Modules for I/O devices. The Lookout

environment has been chosen to implement HMI/SCADA application. For D.C. servomotor,

a cascade control structure is used in order to control the speed from the primary loop and

the current from the secondary loop. The current controller is locally implemented and the

speed controller is remotely implemented using Lookout environment. The cascade control

structure allows the monitoring of control loops variables and the command of the overload

at the servomotor shaft.

2.3 NCS in the hierarchical structure

Hierarchical structure is composed of a computer of the Intranet, called HMI/LabVIEW

with a PCI motion controller board (National Instruments PCI-7354) and Analog & Digital

I/O devices.

DSP controllers available today are able to perform the computation for high performance

digital motion control structures for different motor technologies and motion control

configuration. The level of integration is continuously increasing, and the clear trend is

towards completely integrated intelligent motion control (Kreidler, 2002). Highly flexible

solutions, easy parameterized and “ready-to-run”, are needed in the existent “time-to-

market” pressing environment, and must be available at non-specialist level.

Basically, the digital system component implements through specific hardware interfaces

and corresponding software modules, the complete or partial hierarchical motion control

structure, i.e., the digital motor control functionality at a low level and the digital motion

control functionality at the higher level (see Fig. 2).

Communication protocols

Reference generator

Motion Control

Speed control

Position control

Current control

Pulses control PWM

Motor Control

Real-time operating kernel

Digital

system

Fig. 2. Motion system structure hierarchy.

The National Instruments PCI-7354 controller is a high-performance 4-axis-stepper/D.C.

brush/D.C. brushless servomotors motion controller. This controller can be used for a wide

variety of both simple and complex motion applications. It also includes a built-in data

acquisition system with eight 16-bit analog inputs as well as a host of advanced motion

trajectory and triggering features. Through four axes, individually programmable, the board

can control independently or in a coordinated mode the motion. The board architecture,

which is build around of a dual-processors core, has own real-time operating system . These

board resources assure a high computational power, needed for such real-time control.

Three electrical drive systems, based on a unipolar or bipolar stepper servomotors, D.C.

brush servomotors and a D.C. brushless servomotors are linked to the remote control

architecture. The connection is achieved with the I/O devices from PCI motion controller

Networked Control Systems for Electrical Drives

77

board, which also contains a remote controller implemented using a DSP and real-time

operating system, as is presented in Fig. 3.

CPU (MC68331)

&

DSP (ADSP 2185)

Real-Time

IBM

Operating System

PC

Supervisory;

•

Trajectory Generation;

•

Communications.

•

Control Loop.

•

HMI-LabVIEW

Server

Watchdog

Application

FPGAs

Timer

Encoders;

•

CPU Operation Monitoring.

•

Motion I/O.

•

NI Motion Controller (PCI-7354)

Electrical Drives System

Fig. 3. Motion controller board structure.

Functionally, the architecture of the National Instruments PCI-7354 controller is generally

divided into four components (see Fig. 4):

•

supervisory control;

•

trajectory generator;

•

control loop;

•

motion I/O.

Supervisory Control

IBM

PC

ε*

To Drive

Trajectory Ω*

Analog

Control Loop

&

HMI-LabVIEW Generator

θ*

Digital

Server

I/O

From Feedback & Sensors

Application

NI Motion Controller (PCI-7354)

Fig. 4. Functional architecture of the NI PCI-7354.

Supervisory control performs all the command sequencing and coordination required to

carry out the specified operation. Trajectory generator provides path planning based on the

profile specified by the user, and control loop block performs fast, closed-loop control with

simultaneous position, velocity, and trajectory maintenance on one or more axes, based on

feedback signals.

The LabVIEW environment has been chosen to implement HMI/SCADA application. The

development environment used to complete the applications is LabVIEW 7.0, which beside

the graphic implementation that gives easy use and understanding takes full advantage of

the networking resources. Using NCS hierarchical structure, control architecture for stepper

78

New Approaches in Automation and Robotics

servomotors, D.C. brush servomotors and D.C. brushless servomotors supervisory was

developed which allows the following functions:

-open-loop control of stepper servomotors using constant frequency or prescribed profile

(trapezoidal or S-curve move profile, see Fig. 5);

Velocity

Velocity

[steps/s]

[steps/s]

t [s]

0

t [s]

0

a.

Trapezoidal.

b.

S-Curve.

Fig. 5. Move Profile.

•

closed-loop control of stepper servomotors (speed and position);

•

the operating mode of the stepper servomotors can be with full step, half step or

microstepping mode;

•

open-loop control or closed-loop control of D.C. brush servomotors;

•

self-commutation control of D.C. brushless servomotor speed, which allows very high

speeds;

•

sensorless control for D.C. brushless servomotor.

3. Session description

This section presents three examples to illustrate the manipulation of instruments and real

devices for low power electrical drives education on the Web. These examples exemplify the

laboratory works dedicated to control a D.C. brush servomotor electrical drives system and

a stepper servomotor electrical drives system.

3.1 NCS in the direct structure: D.C. brush servomotor electrical drives system

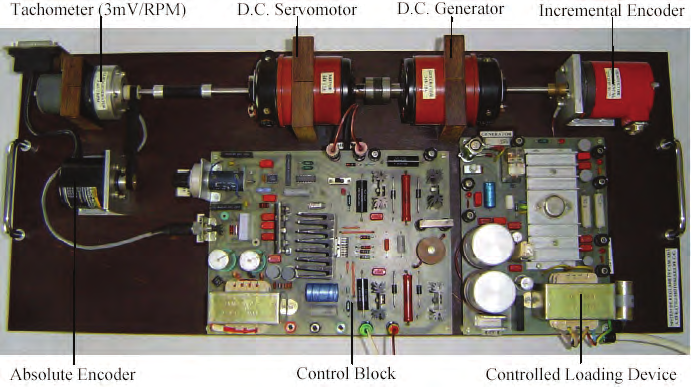

The set-up for D.C. brush servomotor control is presented in Fig. 6 and the layout can be

inspected in Fig. 1.

The set-up consists in a D.C. brush servomotor, a D.C. brush generator used as load, an

incremental encoder and a tachometer as speed transducer, a controlled loading device and

a control block which includes an analogical controller for current loop. The set-up is used

to illustrate cascade control and how this structure can reject the load disturbances. The

primary variable is the motor speed, the secondary is the armature current and the

disturbance is an overload introduced with a D.C. brush generator coupled on the

servomotor shaft. The user has to tune the two controllers of the speed and current loops in

order to obtain optimal performances and disturbance rejection.

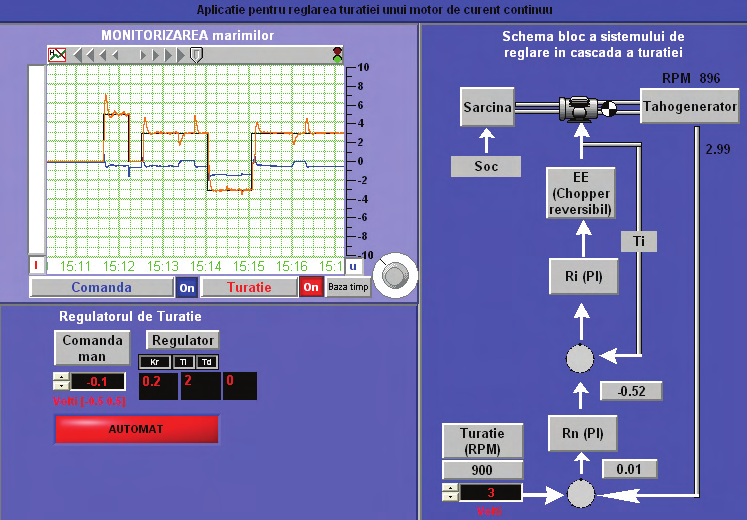

When the application is started, the main panel from Fig. 7 is displayed. The main panel

contains in the right side, the layout of the control system, real time data from the sensors

and actuator and allows the reference setting, the overload command, the choice of

operating mode: manual or automatic and the changing of the tuning parameters of the PI

speed controller (Baluta & Lazar, 2007).

Networked Control Systems for Electrical Drives

79

Fig. 6. D.C. brush servomotor electrical drives system.

Fig. 7. Main panel for D.C. brush servomotor electrical drives system.

All these commands can be done using the left down side of the main panel. In the left up

side, there is a monitor window, which allows the displaying of the main variables of the

control loops. The Monitor window has the possibility to represent only the selected signals

by using on/off buttons or to stop the variables displaying in order to analyse the signals or

to change the time scale through a potentiometer button. All control system real time data

are recorded in a database and can be employed for a future analysis (Baluta & Lazar, 2007).

80

New Approaches in Automation and Robotics

The remote control of the D.C. brush servomotors implements the following functions:

•

the reversible speed control;

•

the on-line tuning of the parameters of speed controller;

•

load command for servomotor shaft.

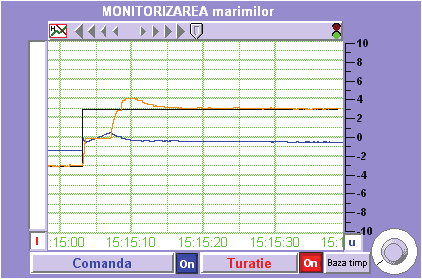

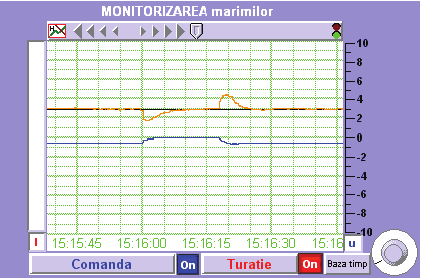

The monitor window of the main panel from Fig. 7 shows both the speed response for a

different set point step variations and the load rejection and the current evolution. Details

regarding disturbance rejection are given in Fig. 8. The numerical controller’s parameters

which have led to such results are Kr=0.2, Ti=2 and Td=0. Due to the well-chosen and

adjusted controller, the system’s response to a step variation of the set point is very good. At

the same time, a good compensation of the disturbance can be noticed (the load torque).

a. Step variation of the set point.

b. Load disturbance rejection.

Fig. 8. Monitoring panel (set point-black, speed-brown, armature current-blue).

3.2 NCS in the hierarchical structure: D.C. brush servomotor electrical drives system

The D.C. brush servomotor has the following features:

•

rating armature voltage Un=20V;

Networked Control Systems for Electrical Drives

81

•

rating armature current In=2A;

•

rating speed nn=2400 rpm;

•

armature winding resistance Ra=1.31 Ω;

•

armature winding inductance La=7.58 mH.

The D.C. brush servomotor is driven by a reversible chopper with the L292 specialized

integrated circuit (Baluta, 2004). The motor’s shaft is connected with an incremental optical

encoder that gives 1000 pulses/rev. (this means 4000 pulses/rev. at the output of the NI

PCI-7354 controller). The D.C. brush servomotor is loaded using a controlled loading device.

Among the features of the loading system, the authors emphasize (Baluta, 2004):

•

the possibility to load the electric drive motor with a reactive load torque in a wide

range of speed, including very low speeds;

•

the possibility to impose a constant load torque operation mode or an overload

operation mode.

The implemented control system uses the algorithm from Fig. 9, which allows to generate in

real-time the move trajectory and to change the motion parameters. In order to program the

motion control system, the developer employs LabVIEW environment with specific virtual

instruments for motion control from the FlexMotion library.

Read Maximum Velocity

Read Maximum Acceleration

Read Maximum Deceleration

Set Operation Mode

Read Final Position

Start Motion

Loop Waiting for Move Complete

Read (Update) Position and

and Move Constraints

Start Motion (Optional)

Perform Non-Motion

Measurement

Fig. 9. Position-based straight-line move algorithm.

Within such application, the user has the possibility to study either:

•

the command regimes in speed open-loop ;

•

the position control regimes of the positioning system.

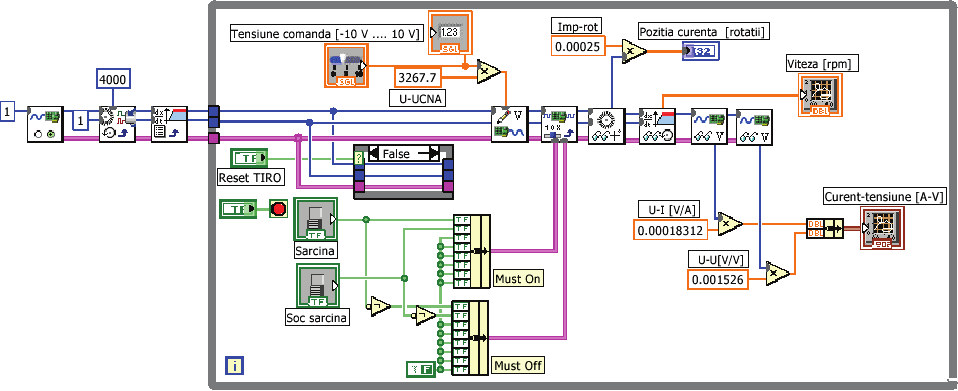

The graphic program associated to the first type of study is that shown in Fig. 10. It is

structured by means of a single while () loop, preceded by an initialization sequence

allowing the configuration of the system (selection of chopper control signal, setting of

82

New Approaches in Automation and Robotics

optical encoder parameters, definition of the speed measurement units). The control

elements of the loop creates the possibility that the user could modify the chopper control

signal and/or to establish the servomotor loading degree. The measures acquired in view of

their graphical representation are the electrical ones (current in the armature winding and

supply modulated voltage of the armature winding) as well as the mechanical ones

(position and speed of the drive system). Leaving off the application is achieved explicitly,

by means the Stop push-button, available in the graphical user interface.

Fig. 10. LabVIEW diagram for the command regimes in speed open-loop.

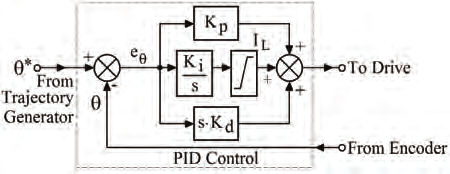

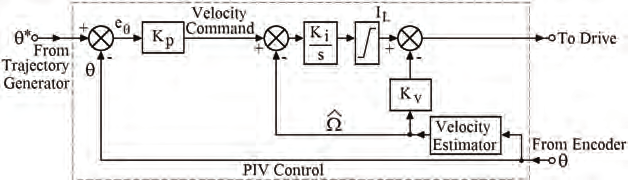

The vast majority of motion control algorithms employed in industrial applications are of

two forms (Ellis & Lorentz, 1999]:

•

the well-known PID position loop (Fig. 11a);

•

an average velocity loop cascaded with a position loop (Fig. 11b).

a. PID Servocontrol topology.

b. PIV. Servocontrol topology.

Fig. 11. Servocontrol topology.

Networked Control Systems for Electrical Drives

83

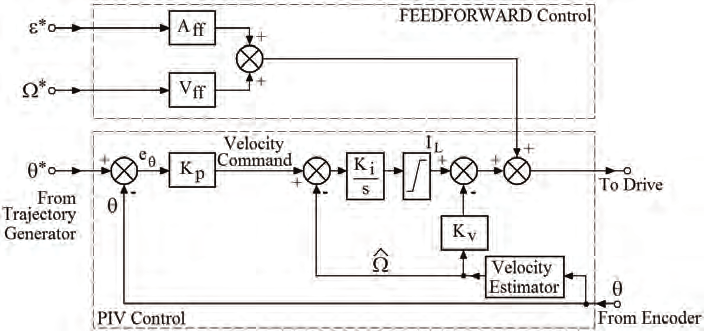

On the other hand, in order to achieve near zero following or tracking error, feedforward

control is often employed. A requirement for feedforward control is the availability of both

the velocity, Ω*(t), and acceleration, ε*(t), commands synchronized with the position

commands, θ*(t).

An example of how feedforward control is used in addition to the second servocontrol

topology is shown in Fig. 12. The National Instruments PCI-7354 controller can be

configured for any of the above servocontrol topologies.

Page 1 Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9 Page 10 Page 11 Page 12 Page 13 Page 14 Page 15 Page 16 Page 17 Page 18 Page 19 Page 20 Page 21 Page 22 Page 23 Page 24 Page 25 Page 26 Page 27