Works like a clock

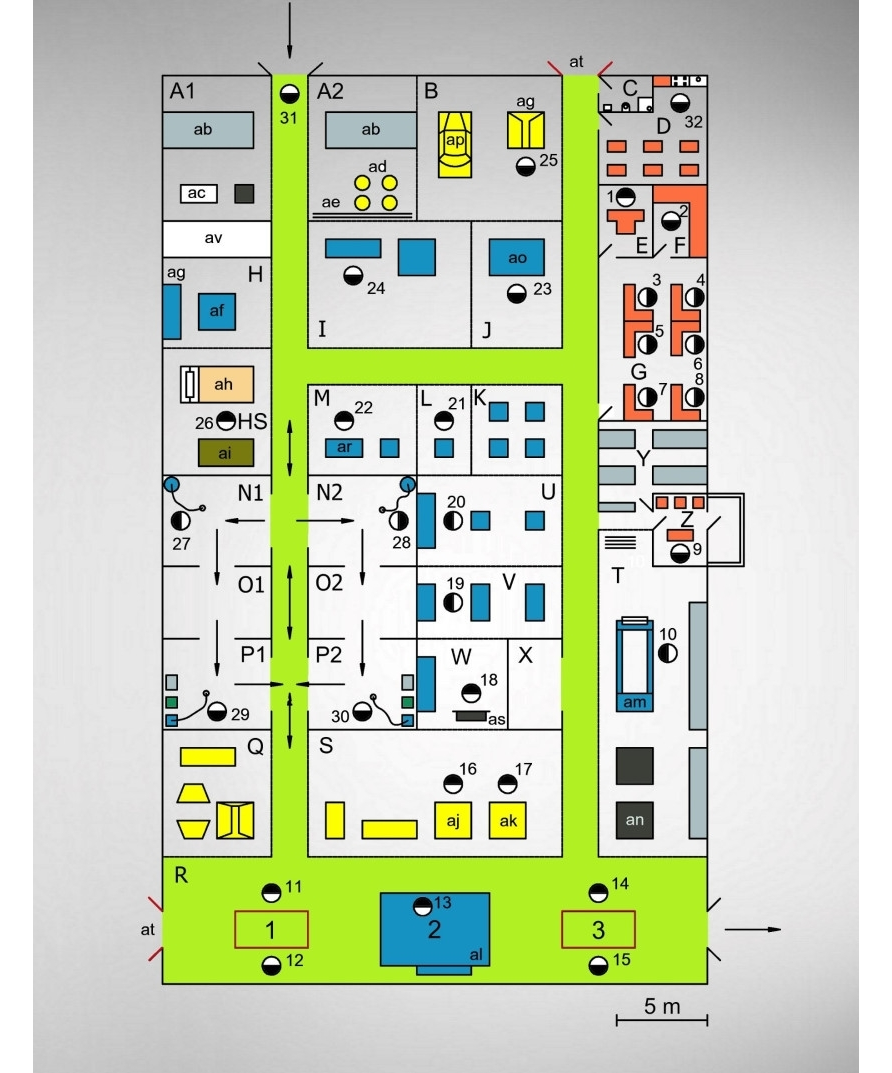

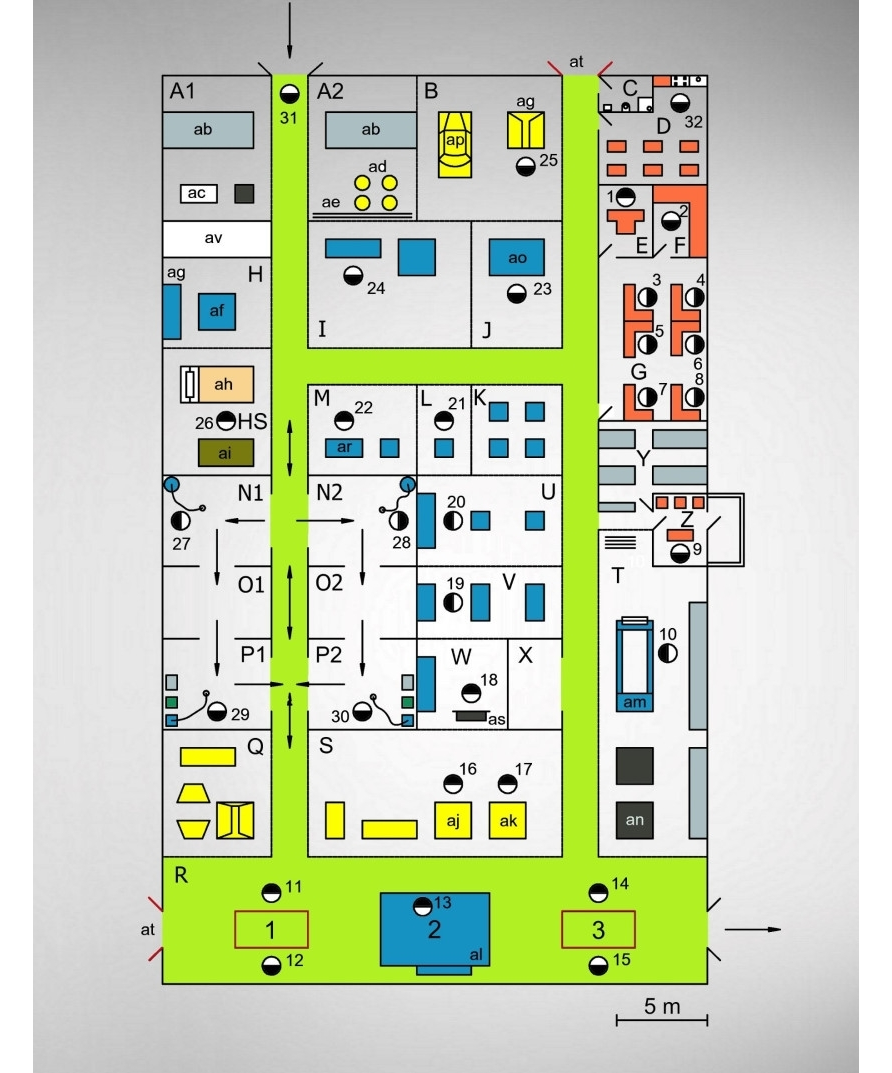

The mini-plant was designed for small-scale production of DOUBIN EVO. This is the first plant of the company which plans to manufacture a car. The plant includes a production line consisting of from three stages. Kitchen D for 35 people. Design Studio B, where the body and interior details will be modeled. Engineering Department G consisting of seven people. Changing room Y. Production areas I, H, G, J, K, L, M, X, R, etc. The total area of the plant is 1500 m2. In the first stage of the production line, the body is assembled. The glass material from which the body parts are made is cut at the HS section. The cut glass material on the table ah fits into the matrix of the body part ai.

Part matrix ai taken from model ag in design studio B arrives at molding hall N1 or N2

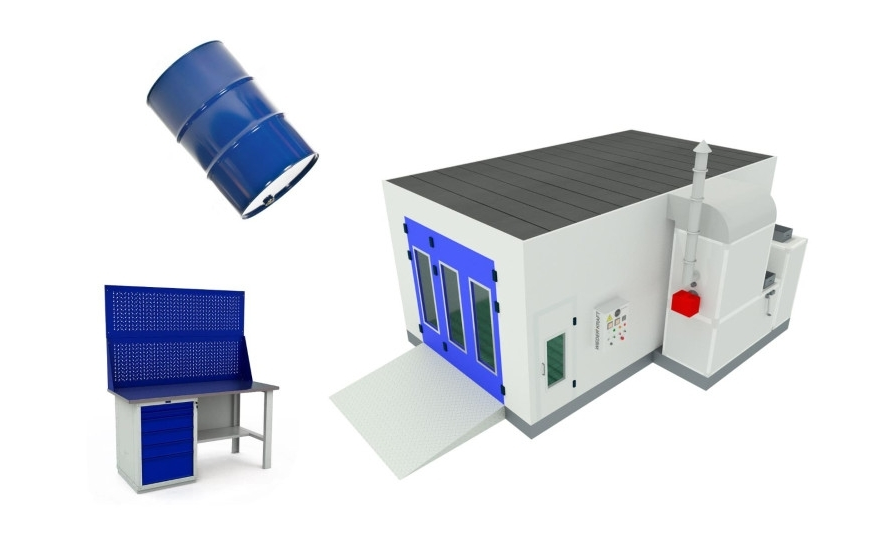

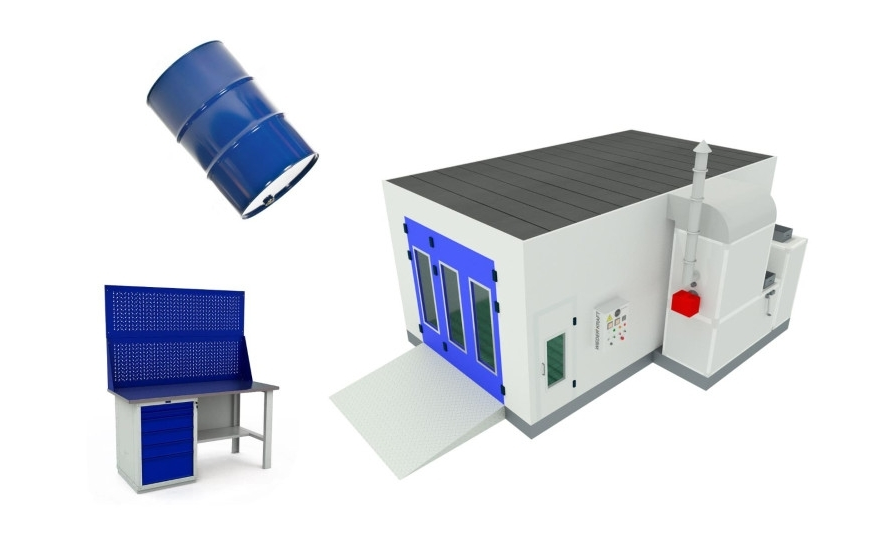

The technological process of cutting takes less time for the forming process, therefore, there are two forming halls N1 and N2 in the production process. When molding a body part in halls N1 and N2, the glass material is impregnated with epoxy resin and then enters the O1 and O2 oven to dry. After the furnaces O1 and O2, the die with the part enters the machining halls P1 and P2 for extracting the part from the die and machining, in which the flash is removed from the part and technical holes are made. After machining, the part goes to the finished parts warehouse Q or to the assembly area R if it is part of another part. All body parts are assembled in the first stage of production. After the assembly process in the first stage, the body enters the spray booth al of the second production stage. Body painting is a lengthy and complex procedure, consisting of several stages. The first stage of body sanding requires excellent ventilation, which should not only remove dust from inside the spray booth, but also filter the air entering the booth. After paint is applied, hot air is blown into the booth to dry the paint.

DUBINA mini-factory.

After painting, the car body goes to the third final stage of production. Two workers numbered 14 and 15 in a certain order install all the equipment of the car and install the electrical wiring. The body is equipped with a power plant assembled at site V, a battery assembled at site T, a dashboard assembled at site W. After installing the parts, the workers check the operation of all vehicle systems and after that the car is ready to pass into the hands of its owner.

Production stages: Stage 1 — body assembly; Stage 2 — body painting; Stage 3 — equipment installation.

Production areas: A1, A2 — warehouse; B — design studio; С — bathroom; D — kitchen; E — captain’s bridge; F — robotics engineer room; G — engineering department; H — vacuum forming area; HS — area for cutting materials; I — mechanical section; J — area of CNC machine tools; K — 3D printing area; L — forging and pressing area; M — welding area; N1; N2 — molding hall; O1; O2 — oven 1, 2; P1; P2 — machining hall; Q — parts warehouse; R — production line; S — part assembly area; T — battery assembly area.

Plant personnel: 1- Anton Dubina; 2 — robotics engineer; 3; 4 — software engineer; five; 6 — design engineer; 7; 8 — process engineer; 9 — security guard; 10 — battery collector; 11; 12 — body assembler; 13 — molar; fourteen; 15 — equipment installer; sixteen; 17 — body parts assembler; 18 — dashboard assembler; 19 — power plant assembler; 20 — control system assembler; 21 — 3D printing wizard; 22 — welder; 23 — operator of CNC machines; 24 — locksmith; 25 — modeller; 26 — cutter; 27; 28 — molder; 29; 30 — handler; 31 — storekeeper;

Plant inventory: ab — racks; ac — plastic sheets; ad — barrels of epoxy; ae — profile; af — vacuum former; ag — cockpit model; ah — cutting table; ai — matrix of a part for molding from a composite; aj — cockpit assembly slipway; ak — roof assembly slipway; al — spray booth; am — battery manufacturing machine; an — battery case; ao — cnc machine; ap — car body model; as — dashboard; ar — welding station.