Significant progress has been made in thin film solar cells that have demonstrated efficiency

in excess of 30 percent for GaAs based multijunction solar cells, which are being used for

space mission [39]. There are several different configurations that would allow high

efficiency solar cells. More recently, there is interest in using GaN / InGaN and ZnO /

MgZnO for development of high efficiency multijunction solar cells [40].

Fig. 17. Band gap energy for solar spectrum. Several material systems are being developed

to provide high efficiency multijunction solar cells. These include material components Ge,

GaAs and GaInP, InGaN and ZnO. [Wu et al; Reference 40]

Figure 17 presents complete solar spectrum for AM-1.5 solar cells. Different material

systems can be utilized to accomplish high efficiency multijunction solar cells. Most of the

multijunction solar cells have been developed for space missions where availability of high

efficiency is of paramount importance and issue of radiation hardness is critical success for

the space missions. There has been significant effort for development of low cost

technologies that will allow high efficiency thin film solar cells for terrestrial applications.

ZnO Nanostructures for Optoelectronic Applications

191

ZnO is being explored as one of the key components for a variety of low cost thin film and

nanostructure based solar cells. Recent work reported by Ganguly and his coworkers [41]

has explored the use of amorphous silicon solar cells with ZnO with insertion of

Germanium layers. They have shown that with insertion of a thin amorphous germanium

layer at the ZnO-p-layer interface improves the cell performance and diode ideality by

suppression of Oxygen and Zinc incorporation in the silicon layers. One of the advantages

of ZnO is is its resistance to hydrogen plasma induced darkening and higher transmission

thereby improving the solar cell efficiency.

Recent work by Peiro and his coworkers [36] at Imperial college and Manchester in UK have

shown that solar cells fabricated from composites of conjugated polymers with

nanostructure ZnO are of great interest for their stability, low cost and electron transport

properties. ZnO polymer solar cells are promising for low temperature synthesis.

Zinc oxide (ZnO)/polymer solar cells are promising compared to other metal

oxide/polymer combinations, on account of the possibility of low temperature synthesis, as

well as the potential for controlling interface morphology through simple processing from

solution. They have focused on the effect of surface morphology of ZnO films on

photovoltaic device performance. They have successfully grown ZnO nanorods standing

almost perpendicular to the electrodes on a flat, dense ZnO “backing” layer.

They have studied [ 36, 37] structures consisting of a conjugated polymer in contact with

three different types of ZnO layer: a flat ZnO backing layer alone; ZnO nanorods on a ZnO

backing layer; and ZnO nanoparticles on a ZnO backing layer. They also used scanning

electron microscopy, steady state and transient absorption spectroscopy and photovoltaic

device measurements to study the morphology, charge separation and recombination

behavior and device performance of the three types of structures.

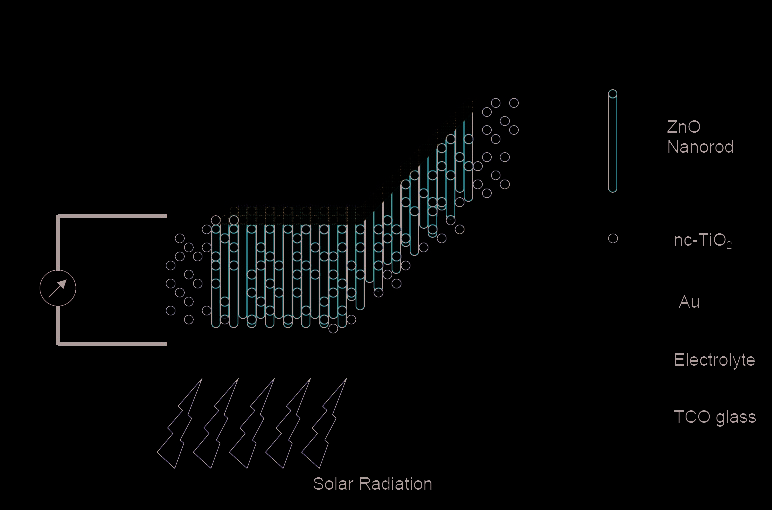

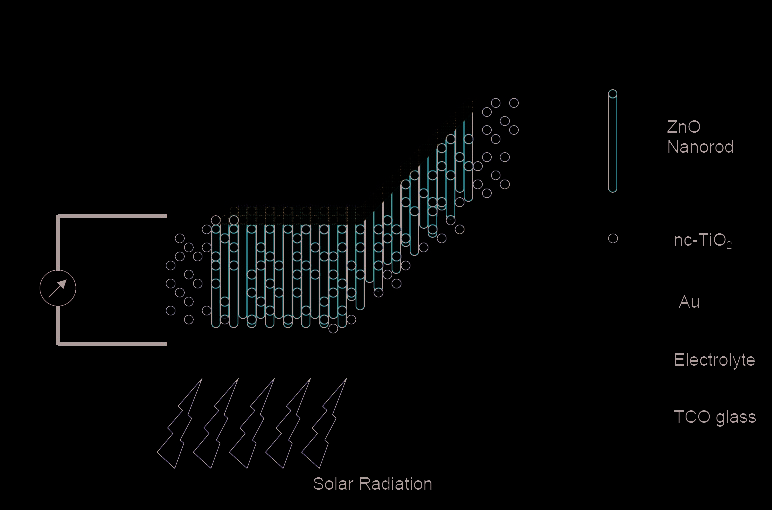

Fig. 18. Schematic diagram of ZnO based nanostructure solar cell [Sridhar et al; Ref 34]

They found that charge recombination in the structures containing vertically aligned ZnO

nanorods is remarkably slow, with a half life of over 1 ms, over two orders of magnitude

slower than for randomly oriented ZnO nanoparticles. A photovoltaic device based on the

nanorods structure which has been treated with an ambiphilic dye before deposition of

poly(3-hexyl thiophene) (P3HT) polymer shows a power conversion efficiency over four

times greater than for a similar device based on the nanoparticles structure.

192

Optoelectronic Devices and Properties

The best ZnO nanorods: P3HT device yields a short circuit current density of 2 mAcm-2

under AM1.5 illumination (100mWcm-2) and peak external quantum efficiency over 14%,

resulting in a power conversion efficiency of 0.20%. Their effort demonstrates the potential

of ZnO nanostructure based solar cells have the potential of low cost and further

improvements can yield higher efficiency solar cells.

Several other groups in US, China and England [34, 36, 41, 42] are working on ZnO

nanostructure solar cells. They are all trying to develop the necessary understanding for

growth and characterization of ZnO nanostructures on variety of substrates.

Investigation of ZnO nanorods based solar cells is being conducted towards developing

alternative, lightweight, flexible devices for commercial applications. A schematic view is

shown in figure 18 .A lot of research has been done in the area of dye sensitized solar cells [

37, 42] in particular, which is currently the most stable and efficient excitonic solar cell.

Aligned ZnO nanorods, with their high carrier mobilities serve as the conduction pathways

for the excitons. These approaches provide a glimpse of what is being done on using ZnO

nanostructures fro solar cell applications. Further effort is needed in developing ZnO based

solar cells that can be implemented in terrestrial applications.

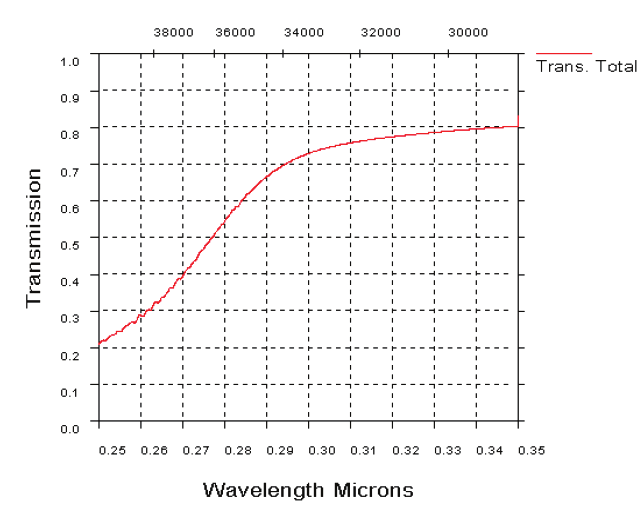

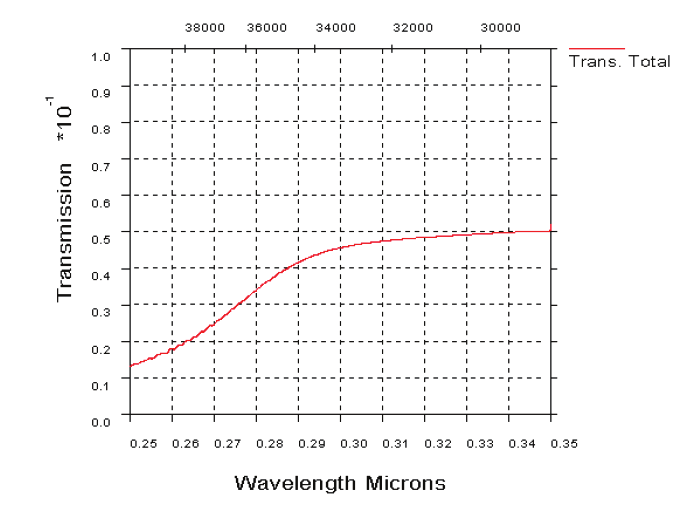

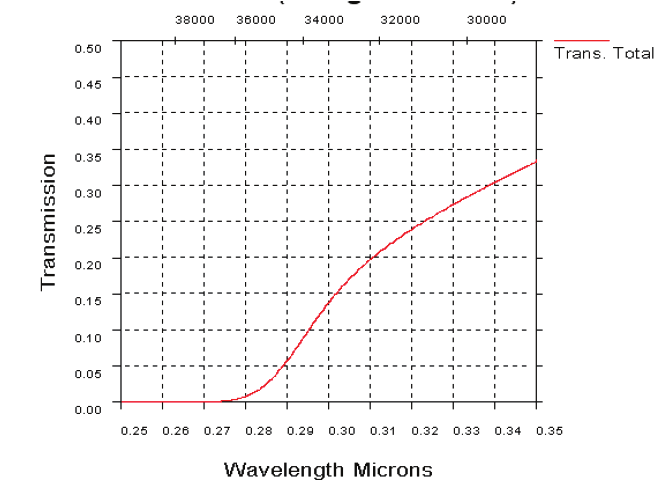

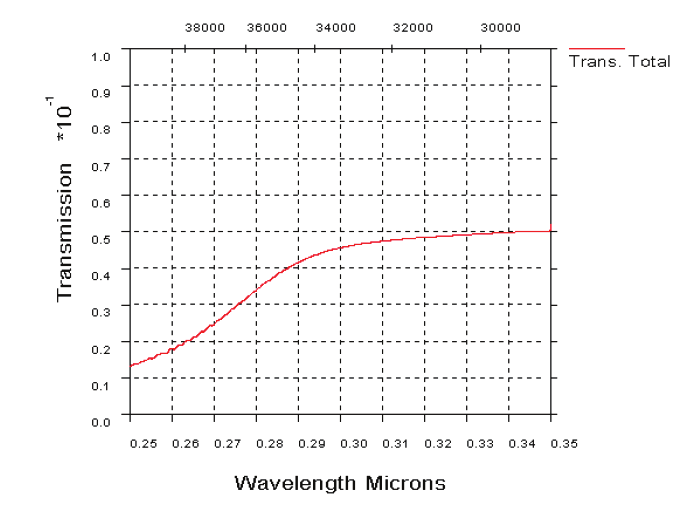

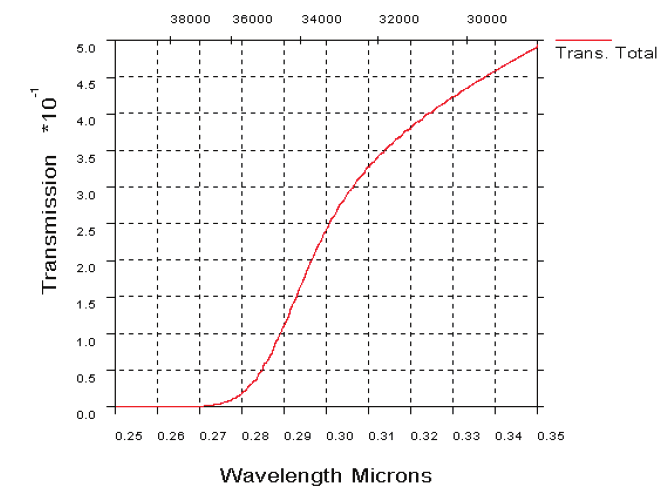

11. UV atmospheric transmission model

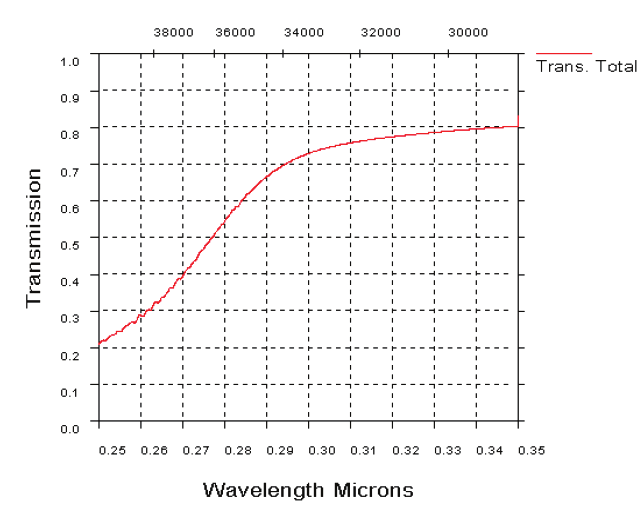

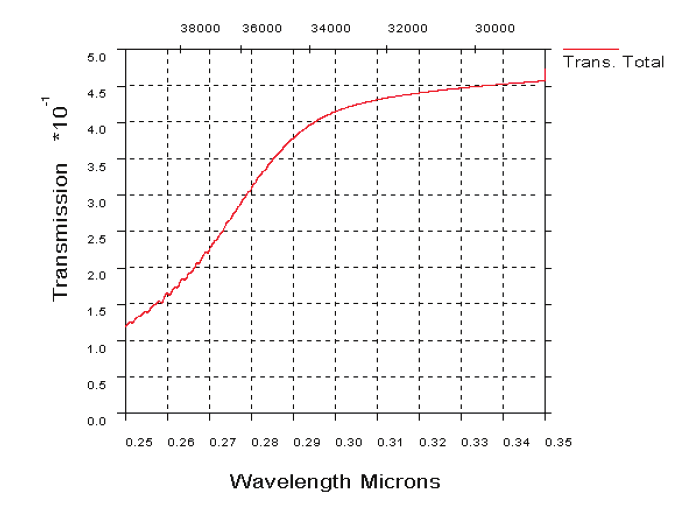

There has been recent effort to study the atmospheric transmission models in UV, Visible

and Infrared (IR) bands [43]. Modeling of atmospheric effects on transmission at UV

wavelengths (250-350 nm range) was performed using MODTRAN. MODTRAN

(MODerate resolution atmospheric TRANsmission) is an atmospheric radiative transfer

model that may be used to determine the effects of various atmospheric layers and weather

conditions on wavelength dependent free-space transmission. Six different atmospheric

models were simulated: clear maritime (23 km visibility), desert extinction, drizzle (2

mm/hr), light rain (5 mm/hr), moderate rain (12.5 mm/hr), and heavy rain (25 mm/hr).

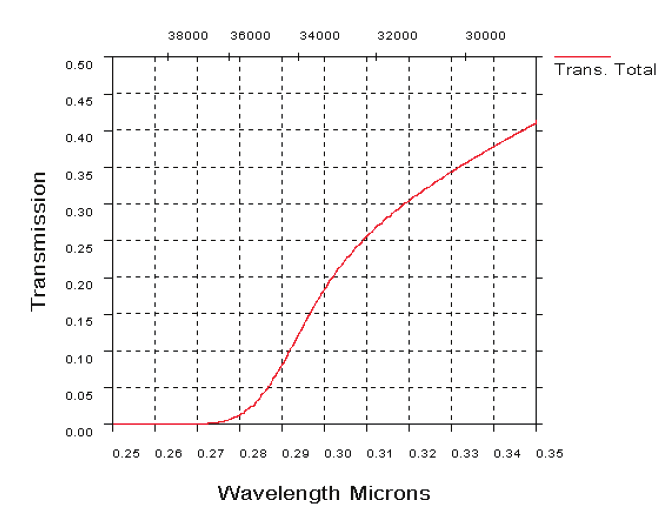

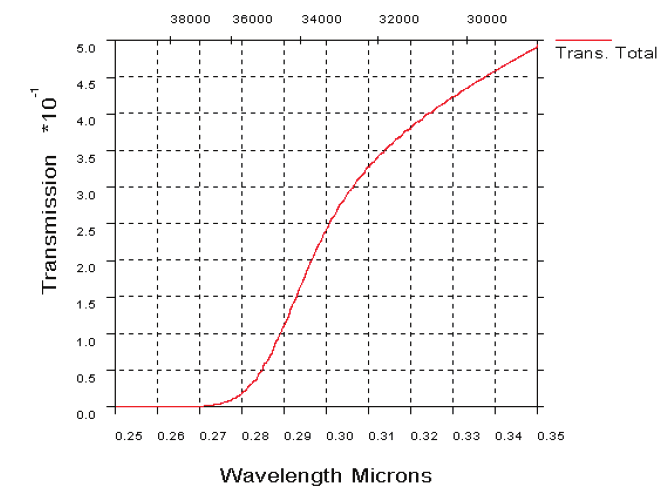

(a)

(b)

Fig. 19. UV atmospheric transmission over a horizontal path in clear maritime (23 km

visibility) conditions, 1 km range (19 a). UV transmission through atmosphere over a

horizontal path in desert extinction conditions, 1 km range (19b)

ZnO Nanostructures for Optoelectronic Applications

193

For each of these weather conditions, UV transmission was modeled for 1 km horizontal

paths through the atmosphere 5 m above the surface (Figures 1-6). In addition, slanted

paths at angles of 15º, 30º, 45º, and 60º from the horizon for a distance of 10 km were

simulated in clear maritime conditions (Figures 19-23) to show the relative effects of

propagation though different lower atmospheric layers on attenuation. In relation to free-

space optical communication networks, a 0º horizontal path would involve ground based

communication extending no further than the horizon, while an upward slanted path might

involve communication between a ground-based unit or sea vessel and an aircraft [43].

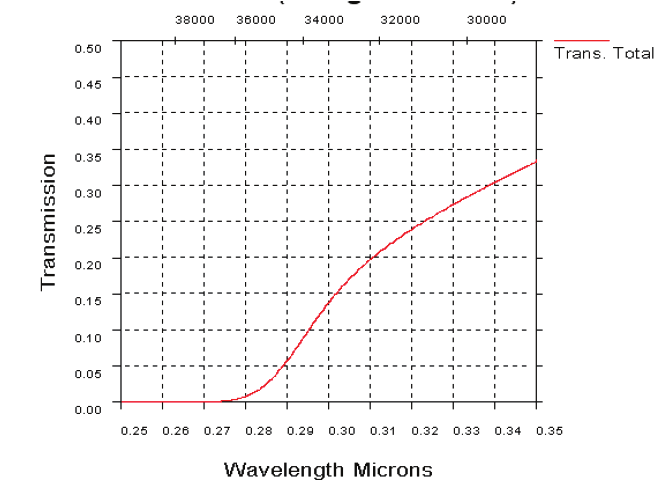

(a)

(b)

Fig. 20. UV atmospheric transmission over a horizontal path in drizzle (2 mm/hr)

conditions, 1 km range (20a) and UV transmission over a horizontal path in light rain (5

mm/hr) conditions, 1 km range (20b).

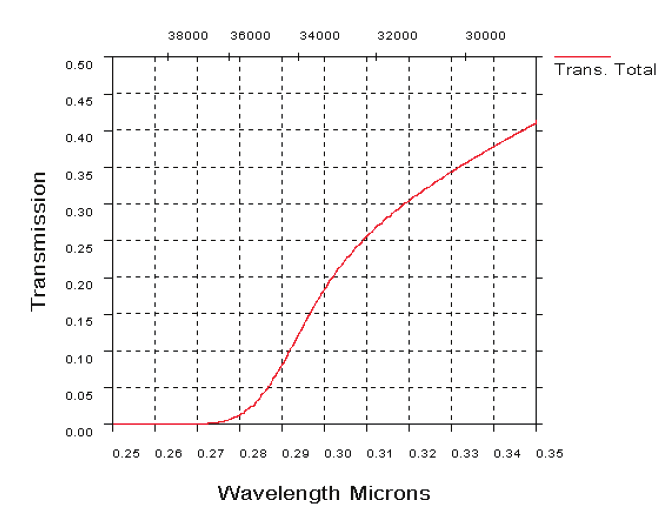

(a)

(b)

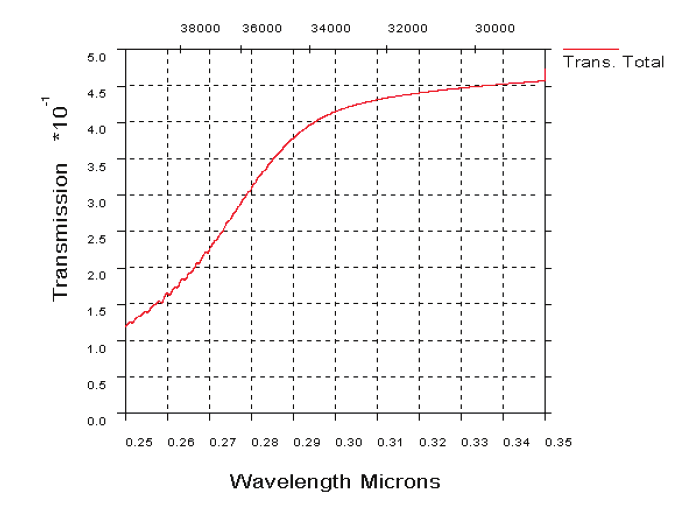

Fig. 21. UV transmission through atmosphere over a horizontal path in moderate rain (12.5

mm/hr) conditions, 1 km range (21a). UV transmission over a horizontal path in heavy rain

(25 mm/hr) conditions, 1 km range (21b)

194

Optoelectronic Devices and Properties

(a)

(b)

Fig. 22. UV atmospheric transmission over a slanted path at 15º elevation in clear maritime

conditions, 10 km range (22a). UV transmission over a slanted path at 30º elevation in clear

maritime conditions, 10 km range (22b)

(a)

(b)

Fig. 23. UV transmission over a slanted path at 45º elevation in clear maritime conditions, 10

km range (23a). UV atmospheric transmission over a slanted path at 60º elevation in clear

maritime conditions, 10 km range ( 23b)

12. Summary

In this chapter, we have discussed growth, fabrication and characterization of ZnO

nanostructures materials and devices on a variety of substrates. ZnO nanostructures offer

potential for a variety of optical, electronic and biological devices for nanoscale applications.

The Zinc oxide nanostructures are also attractive for energy generation devices and

photovoltaic applications. Significant research effort is underway on ZnO nanostructures,

their unique properties for application in transparent electronics, ultraviolet (UV) light

emitters, piezoelectric devices, chemical sensors and spin electronics.

ZnO Nanostructures for Optoelectronic Applications

195

An assortment of ZnO nanostructures, such as nanorods, nanotubes and nanorings, have

been successfully grown via a variety of methods including chemical vapor deposition,

thermal evaporation, hydrothermal technique, sol-gel and electro-deposition. These

nanostructures have been evaluated for electronic devices, UV detectors, light emitting

diodes, lasers, gas sensors, and other biological applications. Further work is underway that

will enhance our understanding of ZnO nanostructures and their applications for future

system applications.

13. Acknowledgement

The authors would like to acknowledge the contributions of many students at Georgia Tech

that have over the years contributed to the exciting work, which has been published by

them and presented here in the chapter. We would also like to acknowledge the modeling

effort by Dr. John Zeller of NUWC, Newport, RI. The authors would also like to

acknowledge the financial support by numerous agencies that have contributed to the ZnO

nanostructures and their applications.

14. References

[1] J. R. Choi and Dennis. L. Polla Journal of Micromechanical Micro-engineering Volume 3, 60-

64, 1993

[2] E. J. Egerton, A. K. Sood, R. Singh, Y. R. Puri, R. F. Davis, J. Pierce, D. C. Look and T.

Steiner, Journal of Electronic Materials Vol.34, No.6, 2005

[3] Z. L. Wang , A Review Paper, Journal of Physics: Condensed Matter 16, 829-858, 2004

[4] X. Wang, J. Song, C. J. Summers, J. H. Ryou, P. Li, R. D. Dupuis, and Z. L. Wang , J.

Phys. Chem. B, 110 (2006) 7720-7724

[5] X. Wang , J. Song , P. Li , J. H. Ryou , R. D. Dupuis , C. J. Summers and Z. L. Wang , J.

Am. Chem. Soc., 127 (2005) 7920-7923

[6] X. Wang, C. J. Summers and Z. L. Wang, Nano Letters, 3 (2004) 423-426.

[7] Z. L. Wang and J. Song, Science, 312 (2006) 242-246

[8] Z. Fan and J.G. Lu, Journal of Nanoscience and Nanotechnology, Volume 5, 1561-1573 (2003)

[9] R.S. Yang, Y. Ding and Z.L. Wang, Nano Lett. , 4, 1309 (2004)

[10] A.K. Sood, Y.R. Puri, P. Gao, C. Lao, Z.L. Wang, D.L. Polla, M.B. Soprano, Proceedings of

SPIE, Volume 6556, 6556IL ( 2007)

[11] L. Luo, B. Sosnowchik and L.W. Lin, Applied Physics Letters 90, 093101 (2007)

[12] W. Lee, M. C. Jeong and J.M. Myoung, Acta Materialia, 52, 3949-3957(2004)

[13] J. B. Baxter and E.S. Aydil, Journal of Electrochemical Society, 156 (1), H52-H58 (2009)

[14] P. X. Gao and Z. L. Wang, J. Phys. Chem. B 106, 12653 (2002)

[15] P. X. Gao, Y. Ding and Z. L. Wang, Nano Lett. 3, 1315 (2003)

[16] Z. W. Pan, Z. R. Dai and Z. L. Wang, Science 291, 1947(2001)

[17] M. H. Huang, Y. Y. Wu, H. Feick, N. Tran, E. Weber and P. D. Yang, Adv. Mater. 13, 113

(2001)

[18] M. S. Arnold, P.H. Avouris, Z. W. Pan and Z. L. Wang, J. Phys. Chem. B 107, 659 (2003)

[19] Y. Cui and C. M. Lieber, Science 291, 851 (2001)

[20] P. G. Collins, M. S. Arnold and Ph. Avouris, Science 292, 706 (2001)

[21] J. Kong, N. Franklin, C. Wu, S. Pan, K. J. Cho and H. Dai, Science 287, 622 (2000)

[22] Wang, X.D., Ding, Y. Summers, C.J. and Wang, Z.L., J. Phys. Chem. B. 108, 8773 (2004)

196

Optoelectronic Devices and Properties

[23] X. Bai, E. G. Wang , P. Gao and Z. L. Wang, NanoLetters, 3, 1147 (2003)

[24] P. M. Morales and C. M. Lieber, Science 279, 208 (1998)

[25] G.F. Zheng, F. Patolsky, Y. Cui, W.U. Wang, and C.M. Lieber, Nature Biotechnology 23

(2005) p. 1294

[26] X.D. Bai, P.X. Gao, Z.L. Wang and E.G. Wang, Appl. Phys. Letts. 82, p. 4806 ( 2003)

[27] Z. L. Wang, and J. H. Song, Science 312 , p. 242 ( 2006)

[28] J.H. Song, J. Zhou, and Z.L. Wang, Nano Lett. 6 p. 1656 ( 2006)

[29] M.H. Zhao, Z.L. Wang, and S.X. Mao, Nano Lett. 4 (2004) p. 587

[30] Z.L. Wang, X.Y. Kong, and J.M. Zuo, Phys. Rev. Letts. 91 (2003) p. 185502

[31] Z.L. Wang and J. H. Song, Science, 312 , 242-246 ( 2006)

[32] P.X. Gao, J.H. Song, J. Liu and Z.L. Wang, Advanced Materials, 19, 67-72 (2006)

[33] X.D. Wang, J.H. Song, J. Liu and Z.L. Wang, Science, 316, 102-105 ( 2007)

[34] D. Sridhar, J. Xie, J.K. Abraham, V. K. Varodan and S.H. Choi, Proceedings of SPIE,

Volume 6172 ( 2006)

[35] W. J. F. Beck, L. H. Slooft, M. J. Wienk, J. M. Kroon, and R.A. J. Janssen, Proceedings of

SPIE, Volume 5938 ( 2005)

[36] A. M. Piero, P. Ravirajan, K. Govender, D.S. Boyle, P.O. O’Brien, D.C. Bradley, J. Nelson

and J.R. Durrant, Proceedings of SPIE , Volume 5938 ( 2005)

[37] J. R. Baxter and E.S. Aydil, Applied Physics Letters, 86, 053114 (2005)

[38] For Silicon Solar Cells, i.e. Evergreen Solar (Marlboro, MA), Schott Solar (Burlington,

MA), and other Silicon Solar Cell Manufacturers). The cell efficiency varies from 14-

18 percent for Polysilicon to Single Crystal Silicon Solar Cells.

[39] T. Takamoto, E. Ikeda, H. Kurita and M. Ohmori, Applied Physics Letters, 70, 381 ( 1997)

[40] J. Wu, W. Walukiewicz, K. M. Yu, W. Shan, J. W. Ager, E.E. Haller, H. Lu, W.J. Schaff,

W.K. Metzer and S. Kurtz , Journal of Applied Physics, Volume 94, 6477 ( 2003)

[41] G. Ganguly, D.E. Carlson, S. S. Hyedus, D. Ryan , R. Gordon, D. Pang and R. C. Reedy,

Applied Physics Letters 85, p 479 ( 2004)

[42] Z. Longyue, D. Songyuan, X. Weiwei and K. Wang, Plasma Science and Technology,

Volume 8, No2, March 2006

[43] J. Zeller and T. Manzur, Proceedings of SPIE, Volume 7833, 783313 (2010)

10

Hybrid Optoelectronic and Photovoltaic

Materials based on Silicon Nanocrystals and

Conjugated Polymers

Vladimir Svrcek

Research Center for Photovoltaics,

National Institute of Advanced Industrial Science and Technology (AIST),

Central 2, Umezono 1-1-1, Tsukuba, 305-8568

Japan

1. Introduction

Hybrid material, which combines advantages of both organic and inorganic materials, might

offer potential for design of novel type of low cost devices with superior performance

(Schneider et al., 2000; Liu et al., 2008). The large choices for the organic and inorganic

structures offer the possibility to obtain materials with attractive physical and chemical

properties. The morphology of hybrid material at nanoscale might lead to very different

properties from crystalline solids. Particularly molecular structure polymers, conformation

and orientation can have a major effect on the macroscopic properties of novel material

(Coakley et la.,2003). Nanotubes are a promising subclass of nanomaterials owing unique

one-dimensional geometric features that can allow engineering the polymer based material

morphology at low cost. Nevertheless, nanotubes fabrication with diameter comparable

with exciton diffusion lengths of polymers (~ 15 nm) is still a problem. It has to be noted

that among the nanotubes with small diameter (< 5 nm), carbon-based discovered by Iijima

(Iijima 1991) were the first to gain recognition in academia (Marte et al., 2001; Harris, 2002;

Wang et al., 2009). Novel synthetic strategies for generating nanotubes from inorganic

materials have been recently also widely investigated and developed (Tenne et al., 1992;

Zhao, et al., 2004). It is believed that fiber/nanotube-polymer based arrays of material have

much lower reflectance and enable fabrication of thicker devices with increased absorption

compared with thin films.

One of the promising type of polymers used in variety of applications are the conjugated

conductive ones (Inzelt, 2008). It has to be noted that in traditional polymers e.g.

polyethylenes, the valence electrons are bound in sp3 hybridized covalent bonds (Inzelt,

2008). Therefore sigma-bond electrons have low mobility and do not contribute to the

electrical conductivity. Contrary to that conducting polymers have backbones of contiguous

sp2 hybridized carbon centers. As a result a valence electron on each center resides in a pz

orbital, which is orthogonal to the other three sigma-bonds. Then electrons within the band

become more mobile particularly when it is partially emptied. This advantage combined

with the mechanical properties (flexibility, toughness, malleability, etc.) make them

favorable also for optoelectronic applications as an active material.

198

Optoelectronic Devices and Properties

On the other hand, quantum dots, sometimes called as nanocrystals as well, are a special

class of semiconductor. They range in size from 2-10 nanometers in diameter. As a result the

excitons in quantum dots are confined in all three spatial dimensions (Murray, et al., 2000).

Particularly, silicon nanocrystals (Si-ncs) have many advantages over the other nanocrystal

materials (Canham, 1990; Hirsmman 1996). For instance, some of these materials contain

toxic elements such as lead or cadmium, and others rely on elements such as indium that are

in limited supply in nature. Silicon is no toxic and abundant. Newly observed phenomenon

in Si-ncs - so called multiple excitons generation - favorites Si-ncs as promising material for

photodetectors and solar cells (Beard,et al., 2007; Sukhovatkin et al., 2009). Namely the Si-nc

can produce two or three electrons per photon of high-energy sunlight and could lead to a

new type of solar cell with more than twice as efficient as nowadays used one. Colloidal Si-

ncs compared to solidly embedded in matrix allow easier processibility and fabrication of

device at low cost. [6] Free-standing Si-ncs and conjugated polymers blends shown be a

promising optoelectronic and photovoltaic composite material (Švrček et al., 2008a; Lui et

al., 2009).

In first part of this chapter we show that electrochemical etching and laser nanosecond laser

processing in liquid media is suitable for preparing doped (boron and phosphorus) colloidal

and surfactant free Si-ncs. Blends optoelectronic properties consisting of doped Si-ncs and

two conjugated polymers (e.g. (poly(3-hexylthiophene) (P3HT) and poly[methoxy-

ethylexyloxy-phenylenevinilene] (MEH PPV)) are discussed in details. It is demonstrated

that such Si-ncs can be successfully used for fabrication of room temperature

photoluminescent and photoconductive blends. The role of selected Si-ncs synthesis

techniques on the photoelectric properties of blends is compared. We argue that the

luminescence and transport properties of the blends are controlled by Si-ncs properties and

could be assigned to quantum confinement of excitons in Si-ncs. We demonstrate that the

transport properties of the blend can be tuned by processing conditions. The blends

containing Si-ncs produced by the laser ablation clearly evidence superior photovoltaic

properties due to the enhanced bulk-heterojunction surface area and improved charge

transport.

The morphology of the bulk-heterojunction can be significantly affected by various

fabrication parameters during the device formation. In second part of the chapter, in order

to achieve an efficient performance of the bulk-heterojunction, both the size distribution and

mesoscopic ordering of blend in nantubes is discussed. It is shown that a fiber- and/or

vertical 1D-like order of photosensitive bulk-heterojunction gives considerable advantages

over the thin film technology, because it provides larger interfacial area for efficient exciton

dissociation and straight path for photogenerated carries. As a result, fibers help to avoid

circuit shorts and interruption of percolation paths for carriers to their respective electrodes.

In this respect, a capillary induced filtering and assembly of blends in nanoporous templates

is discussed. We show that the titanium/alumina dioxide (TiO2/Al2O3) nanotubes template

could be suitable candidate for vertical order of photosensitive based blends.

2. Experimental methods

Colloidal and surfactant free Si-ncs with quantum confinements effects were prepared by

two independent techniques. First by electrochemical etching and second by laser ablation

of silicon wafer in water. For this purpose, boron-doped wafer with a resistivity of 0.5–

Hybrid Optoelectronic and Photovoltaic Materials based on

Silicon Nanocrystals and Conjugated Polymers

199

0.75Ocm (p-type, B concentration of 3x1016cm3) and phosphorous-doped wafer with a

resistivity of 0.5–2Ocm (n-type, P concentration 2x1016cm3) were used. The wafers were

electrochemically etched in a mixture of hydrofluoric acid with pure ethanol (HF:C2H5OH

1:4). In order to obtain a similar size distribution of Si-ncs, a constant current density 3.2

mA/cm2 and a constant etching time 60 min were used for the B-doped Si-ncs. In the case of

P-doped Si-ncs, we kept a constant current density at 1.6mA/cm2. In this process, the

etching time was 90 min and a halogen lamp illuminated the P-doped silicon substrate

during the electrochemical etching. The B- and P-doped and red luminescent Si-ncs were

harvested by mechanical scratching (Švrček et al., 2004). Second technique goes after the

synthesis route of blue luminescent Si-ncs based on a water-confined nanosecond laser

ablation process [Švrček et al., 2006; Švrček et al., 2009]. Particularly, the Si-ncs are prepared

by nanosecond excimer pulsed laser (KrF, 245 nm 20 Hz, 20 ns). Crystalline silicon doped

wafers with same charact