value can be once again determined by displacement over the two following reference

marks that is after displacement of 20μm. The manufactured angular transducers with the

length-coding reference marks have 36 reference marks on the discs with 900 and 18000

lines, while the scales with 36000 lines have 72 reference marks. Rotations which do not

cross adequately 20º or 10º are adequate to establish another absolute position.

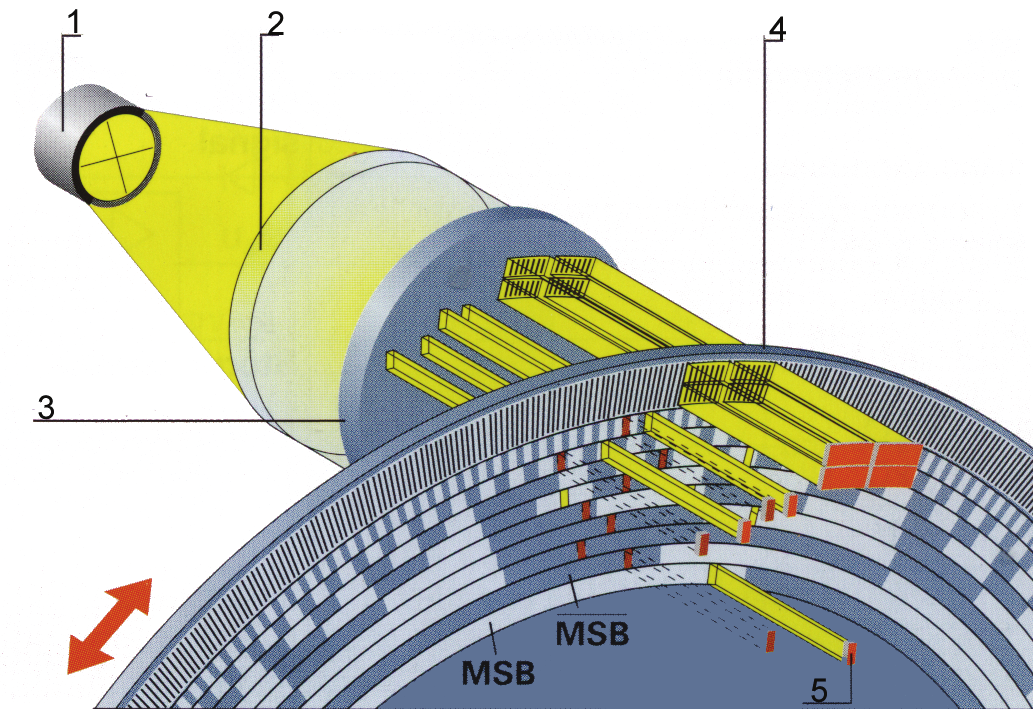

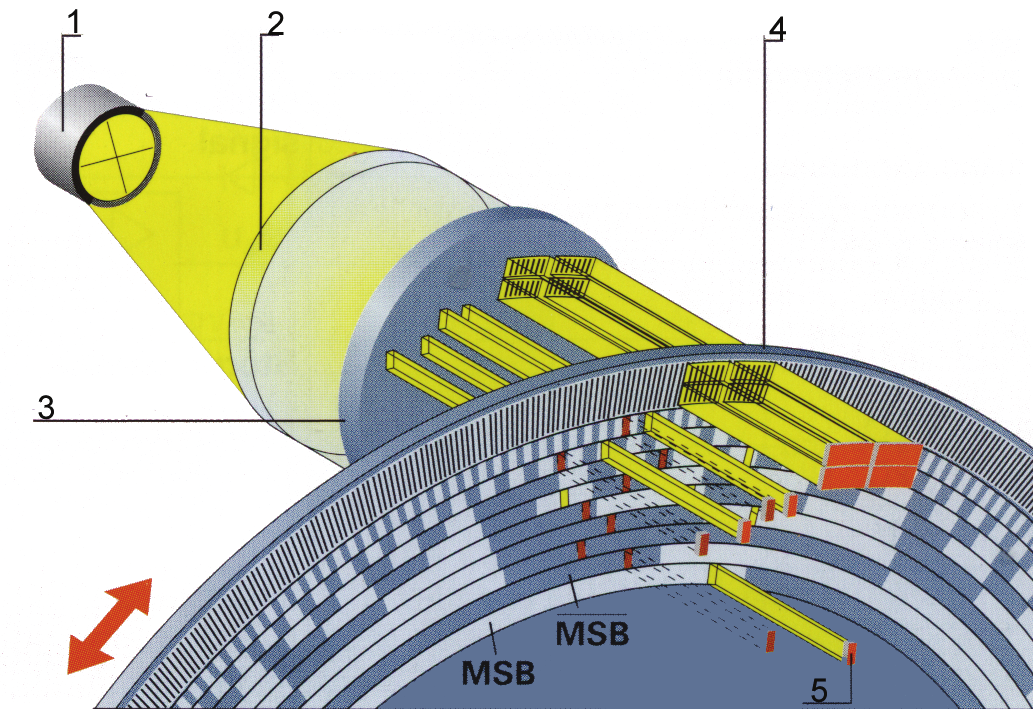

3. Optoelectronic coding transducers

The main element of the coding transducer (fig.2) is the rotating coding mask. Each position

of the coding mask (that is each possible to distinguish by given transducer value of

measured quantity) corresponds to the determined combination of transparent and

nontransparent fields for stream of light. This combination presenting 0 or 1 digits of binary

code is read by photoelectric reading complex which consists of a source of light and photo

elements. For each transducer coding path fall separate light-sensitive element in a way that

on the output of the optoelectronic transducer static code is formed. This depends on the the

actual position of the modulating disc. This code can be used directly as a value of measured

quantity. If necessary the decoder enabling the matching code of the transducer disc to the

code of the reading device can be used. About accuracy conversion decides first of all

digitization error depended on number of bites in the output signal of the transducer. In

fig.2 the code transducer was shown, in practice the transducers of 100..1000 grain

resolution working in binary-decimal code (8..12 -bit) or 128..1024 grain resolution working

in binary code (7..10 -bit). If higher precision is required the transducers with several coding

discs coupled to each other by non-backlash gears are used. In this way in the transducer

with two gears (1:100) received 106 resolutions. The basic advantage of the coding

transducers is the generation of parallel static binary code or binary-decimal code which is

the value of the measured quantity. If there is a need parallel code can be easily converted to

serial code. Conversion can be achieved by subsequent reading of information from

particular coding strips. The drawback of both specified codes is the sensibility to making

gross read errors. It comes from strict assembly tolerances of complex: the glass scale (disc) –

a reading device. Elimination of this drawback can be achieved by special construction

352

Optoelectronic Devices and Properties

means (Heidenhein, 2003) (Holejko, 1981) (i.e. reader in shape of a reversed letter V ) or by

applying instead of binary code different codes in which during the change of measured

value of 1 grain, and the change of a state occur only on one code path (i.e. Grey code).

Absolute measuring devices provide actual information of the position. There are also built

converters which additionally produce incremental signals. (fig.2)

Fig. 2. The construction diagram of the code transducer for measuring angle source of light,

2- condenser lens, 3- scanning reticle, 4- glass scale, 5- solar cells

4. Method of shaping measuring sinusoidal signals of the optoelectronic

transducer

On the glass scale 2, four rectangular fields with scanning reticle 1 are placed. They are

assigned to individual photovoltaic cells. (fig.3)

The parallel light beam produced by the source of light and the lens is incident through the

above mentioned grids on the scale of the scanning reticle and from there on the

photovoltaic cell. The grids have identical widths of light, transparent and opaque fields,

which is a condition for photovoltaic cells to generate sinusoidal voltage signals (Szcześniak,

2005)d (Szcześniak, 2005)g. In order to obtain sufficient signal value, it is advantageous that

the measurement field should consist of N periods T of the displacement division. Then, for

a specified field lit with a radiation beam of intensity Eo, at a given efficiency of the optical

system, we will obtain an effective beam ϕ getting to the photooptic system Ua,Ub,Uc,Ud. We

can form the beam incident on photoelements by placing a scanning reticle with appropriate

relative displacement in relation to the scale index grid 2 of the transducer. The relative

Methods and Devices of Processing Signals of Optoelectronic Position Transducers

353

displacement for the photoelectric system Ua amounts to 0o. The displacement of the

photoelectric system Ub is 1/4 of the period T in relation to the photoelectric system Ua. Its

position is defined by the dependence N2T + 1/4T. On the other hand, the system Uc is

shifted by 1/2 of the period T with respect to the system Ua and of the same period system

Ud is shifted to Ub. The position of this photoelectric system is given by the dependence N1T

+1/2T, N4T + 1/2T. Exemplary positions of the reading fields are presented in the Fig.4. in

which N, N1, N2, N3, N4 denote the number of periods T.

Fig. 3. Method of signal generation in photoelectric position transducer for three

photoelectric systems

We can form the beam incident on photoelements by placing a scanning reticle with

appropriate relative displacement in relation to the scale index grid 2 of the transducer. The

relative displacement for the photoelectric system Ua amounts to 0o. The displacement of

the photoelectric system Ub is 1/4 of the period T in relation to the photoelectric system Ua.

Its position is defined by the dependence N2T + 1/4T. On the other hand, the system Uc is

shifted by 1/2 of the period T with respect to the system Ua and of the same period system

Ud is shifted to Ub. The position of this photoelectric system is given by the dependence N1T

+1/2T, N4T + 1/2T. Exemplary positions of the reading fields are presented in the Fig.4. in

which N, N1, N2, N3, N4 denote the number of periods T.

When the scanning distribution grating is in motion, photovoltaic cells generate sinusoidal

voltage signals :

U = A sinϕ + A , U = A sinϕ + A ,

a

1

o

c

1

o

(1)

U = A cosϕ + A , U = A cosϕ + A ,

b

1

o

d

1

o

354

Optoelectronic Devices and Properties

where: ϕ =2πy/T in addition: A1- signal amplitude, Ao- signal constant component, y -

displacement, T – signal period.

Fig. 4. Diagram of the reading fields of the measurement scale for three photoelectric

systems

Subtracting sinusoidal signals Ua from Uc and Ub from Ud (signals of 180º phase shift), we

get rid of the DC component and receive sinusoidal voltage signal that is symmetrical in

relation to zero and shifted one from another by ¼ of period.

U1=Asinϕ U2=Acosϕ

(2)

The principle of signal processing is presented in Fig.5. The signal period equals the grid

period of the scale T. The method presented in the paper for the compensation of the

signal DC component takes into account its dynamic changes when the transducer

operates under changeable environmental conditions (temperature, humidity, dustiness,

etc.).

Generated signals sin, cos are used to determine the motion direction. They can also be

processed further in order to increase the accuracy of position measurement (Ching-Fen &

Mao-Hong, 2005) (Feel-Soon & Sung-Jun, 2005 ) (Szcześniak & Szcześniak, VIII.2009)

(Szcześniak, 2005)e.

Signals that do not contain a DC component make it possible to generate phase signals and

then multiply the frequency of the signals in comparison to input signals. The generated

signals are rectangular and have pulse–duty factor 0.5. Due to the lack of constant

component in the signal U1, U2 it is possible to directly receive from them rectangular

signals Uw1, Uw2 of pulse–duty factor 0.5. Constant and stable pulse–duty factor ensures

obtaining uniform measurement step α presented in fig.5. The measuring step was defined

as the distance between two subsequent slopes of rectangular signals Uw1, Uw2 (Szcześniak,

2006)b. The number of pulses generated from the slopes of the signals and counted in the

course of measurement gauge shift is the measure of position. Rectangular signals shifted

in relation to each another by ¼ of the period and of pulse–duty factor 0.5 provide the basis

for the determination of the photoelectric transducer motion direction. The method of

shaping measuring signals with compensation of DC constant thus minimizing number of

devices of measuring optoelectronic transducer to three presented in literature (Szcześniak,

2006)b.

Methods and Devices of Processing Signals of Optoelectronic Position Transducers

355

Ua

ϕ

Uc

ϕ

Ub

ϕ

Ud

ϕ

U1

ϕ

U2

ϕ

Uw1

ϕ

Uw2

ϕ

a

Fig. 5. Principle of signal generation in the optoelectronic quantization transducer for

position measurement

5. Methods of processing electric signals of the optoelectronic position

transducers to increase the accuracy of measurement and the motion

direction determining

The development of specialized analog and digital systems allows for processing fast

alternating signals. This means that in practice there are no limits to signal frequency on

356

Optoelectronic Devices and Properties

account of measuring electronic systems. Much more significant are mechanical limits on

account of the dynamic of measured object and its range.

The quantizing transducers (incremental) produce electrical impulse during shift of one unit

of length or angle in a way that on the output of the transducer the number of impulses

proportional to measured value is obtained (Szcześniak & Szcześniak, IV.2009).

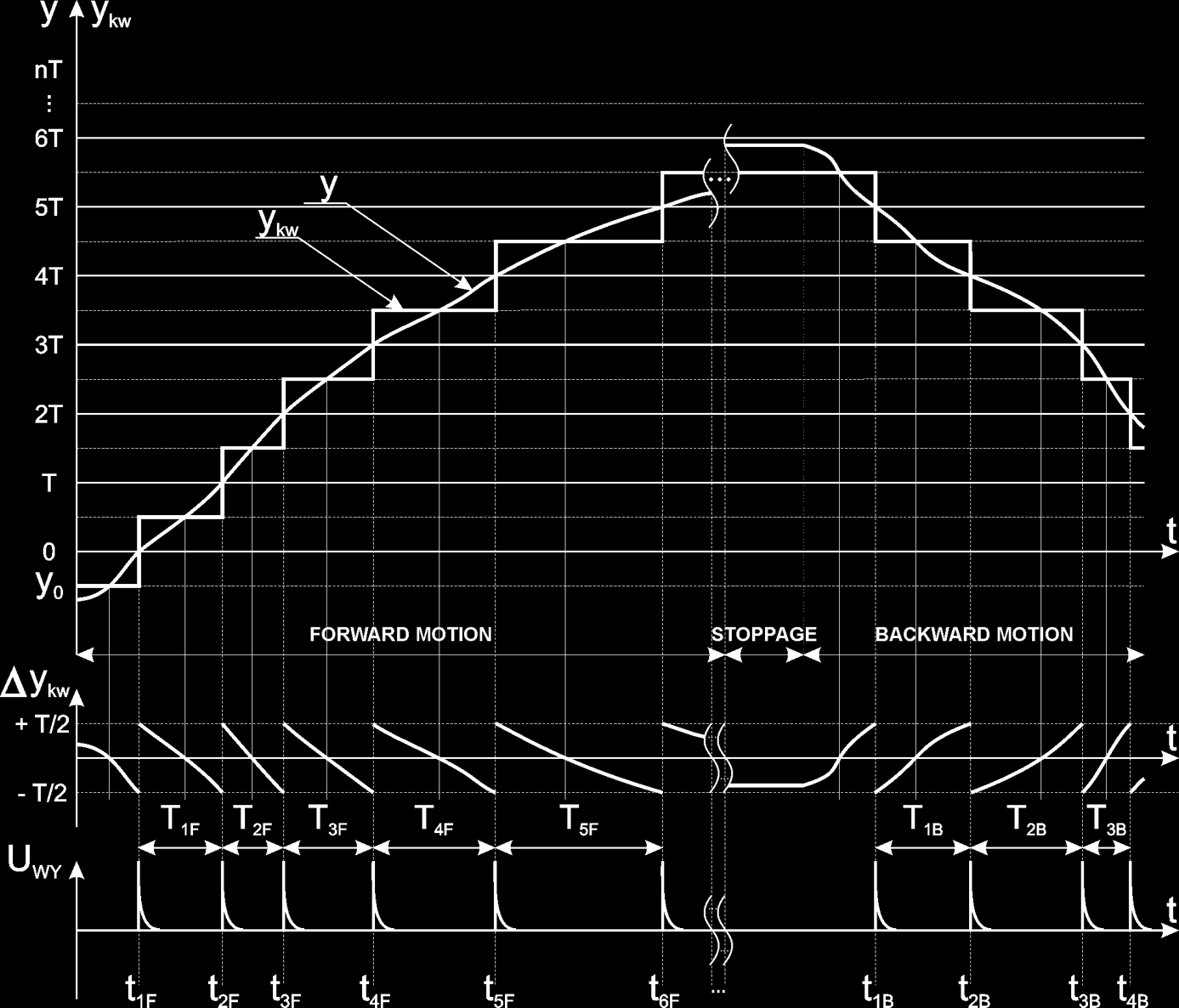

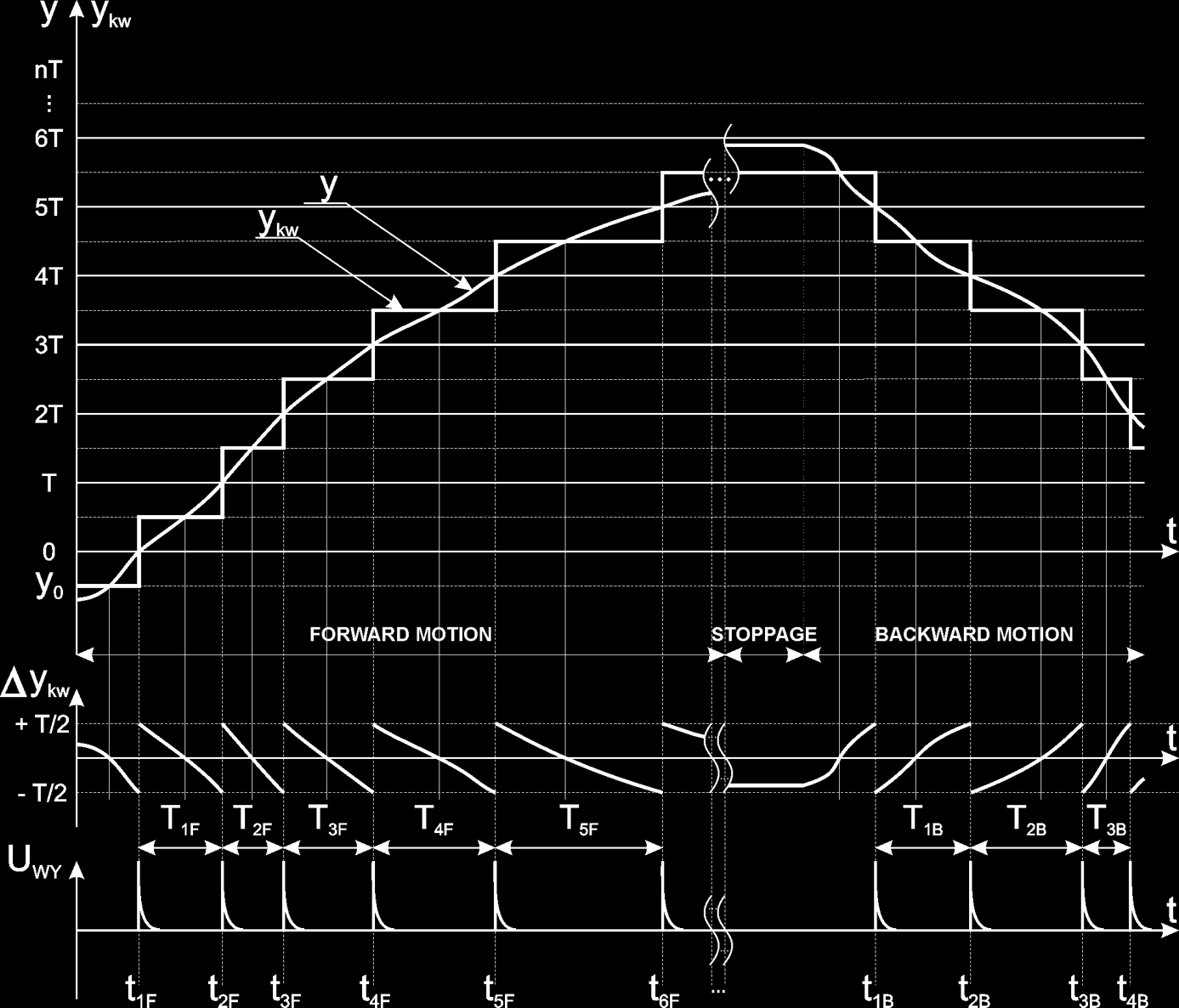

About measurement accuracy of the optoelectronic transducers decides first of all value of

discretisation error which is depended on number of modulation elements fall to number of

linear or angular shift unit. The input signal of the optoelectronic transducer in a form of

variable in time linear or angular velocity is integrated in time resulting in constant

increasing of position y(t) presented in fig.6. Uniformly spaced sequences of light

transparent and nontransparent fields create a measuring scale which conducts rhe

operation of quantization horizontally continuous in position time y(t). Next, quantized

signal of increasing position ykw(t) is differentiated in the circuit of optoelectronic

transducer. Each another increase of position y of unit T (quantum) cause receiving impulse

of output signal Uwy of frequency proportional to velocity moving mechanism. An example

of time signal functions is presented in fig.6.

Fig. 6. Time functions of signals in the optoelectronic position transducer

Position increase from initial value y0 with velocity proportional to value of input signal

(velocity moving mechanism) and is quantized horizontally with step equals T. The position

is presented for three phases of motion: forward motion, stoppage and backward motion.

Error of quantization Δ ykw consist in a range of ±T/2. In particular moment of time t1F, t2F, t3F

position y reaches following values T, 2T, 3T... and on the input of the sensor we receive

Methods and Devices of Processing Signals of Optoelectronic Position Transducers

357

impulses spaced one from another in time of T1F, T2F, T3F... creating output signal of motion

frequency in the forward direction. For the backward motion direction, impulses are

generated in moments t1F, t2F, t3F etc. In the presented figure, motion impulse is generated

based on an equal step of quantization T, but in different moments depending on velocity of

motion so the method of distinguishing the motion direction of the optoelectronic

transducer was used. This method produces one impulse per one period of the glass scale.

Below is presented the electronic method of increasing accuracy of the optoelectronic

transducer by applying electronic interpolation (multiplication of signals` frequencies) and

digitalization (conversion to digital form) and electronic methods of distinguishing motion

direction and measurement of position with possibility of additional increase of

optoelectronic transducer accuracy working with an object.

6. Method for the multiplication of the optoelectronic position transducer

measurement signal frequency

Optoelectronic transducer output signals are composed of two sinusoidal signals, phase

shifted with respect to each other by ¼ of the period. The signal period is equal to the

period of the transducer scale grid (measurement bar). The scanning signals from

transducers are first amplified and then interpolated. The interpolation method proposed by

the authors relies on a network of resistors. It generates phase-shifted signals from two

sinusoidal scanning signals by means of their vector summation in accordance with the

description below. Voltage signals from the sensor

x

= Asinϕ ; y

= Acosϕ (3)

where: ϕ =2Πy/T in addition A- signal amplitude; y- displacement; T- signal period.

In method of interpolation from signals x, y signals x1, x2, x3 etc. are created. Their phase is

shifted to x signal by angle α, 2α, 3α etc. Initial signals can be written as:

x

= A si

nϕ

x 1 = x cos α y

+ s

in α = Α sin (ϕ + α)

(4)

x 2 = x cos 2 α + y

sin 2 α = Α sin (ϕ + 2 α )

In the relationship above, the resistances R1,R2 are defined as :

R

R

R =

=

1

and R

(5)

sinα

2

cosα

where: α - angle of the assumed phase shift, R – adopted signal reference resistance

Generated voltage on the resistance divider is equal to:

U A

= (sinϕ R + cosϕ R )

d

1

2 (6)

Taking into account the above dependences and after transformation we receive

U = A sin(ϕ + α

d

1

) (7)

in addition A1- the amplitude of a signal generated with the assumed phase shift α

358

Optoelectronic Devices and Properties

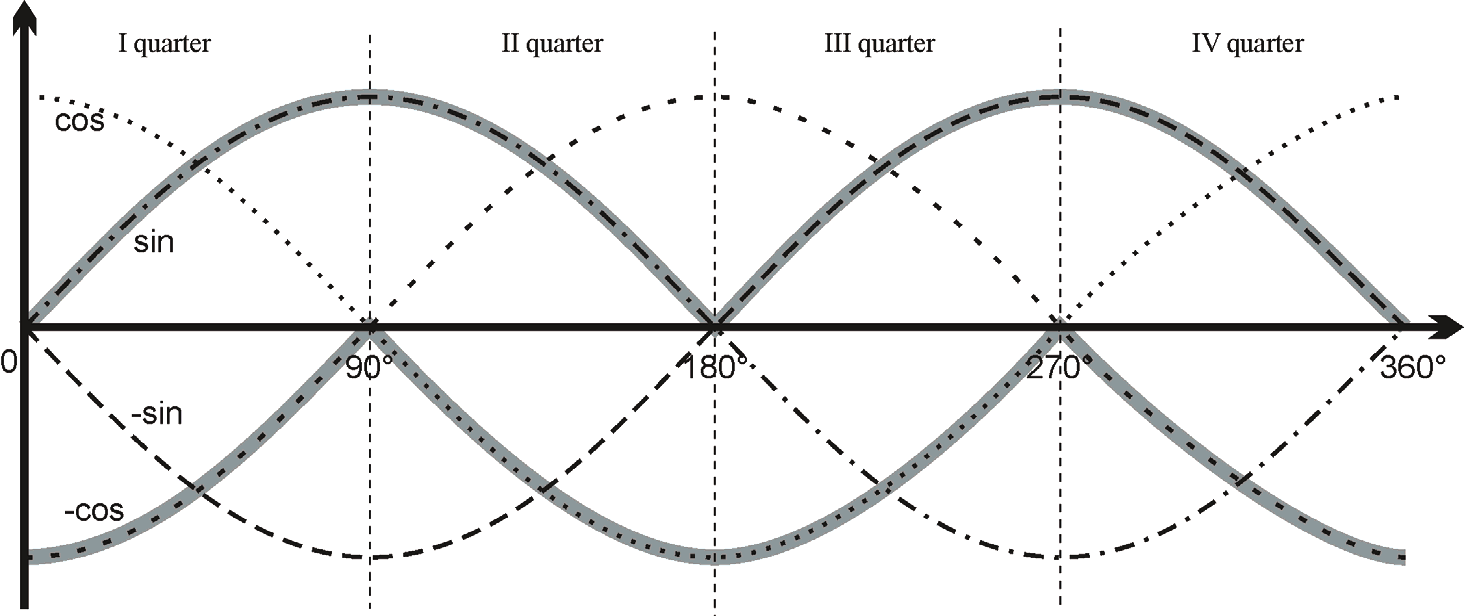

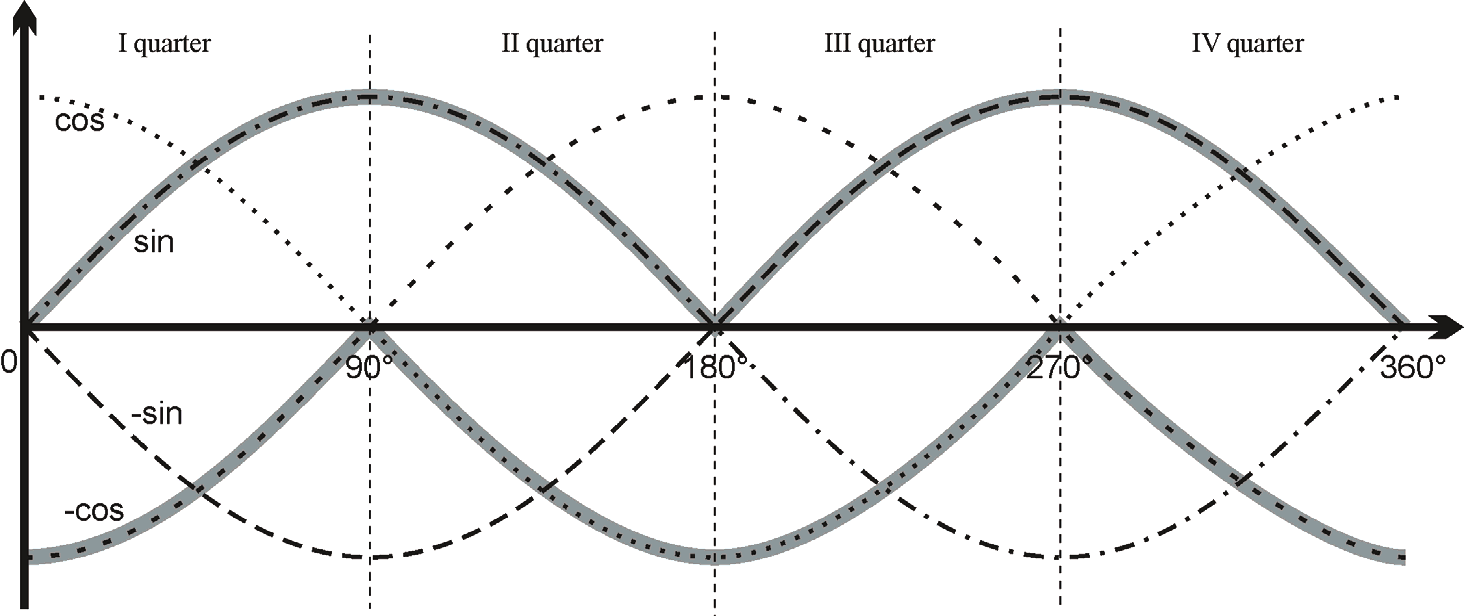

For the sake of the method description clarity, it is assumed that the input signals are of

constant frequencies (periods). This case represents the transducer collaboration with the

object moving at constant velocity.

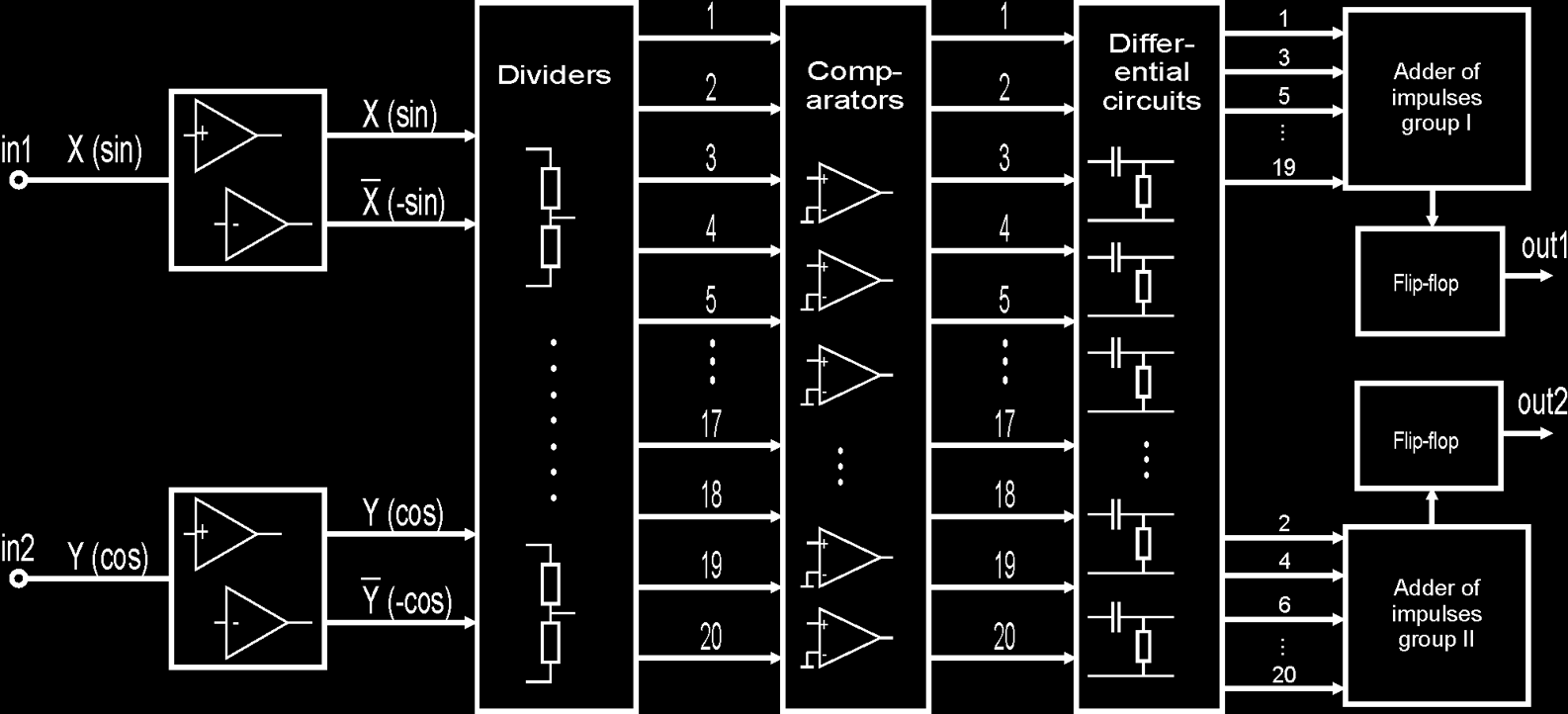

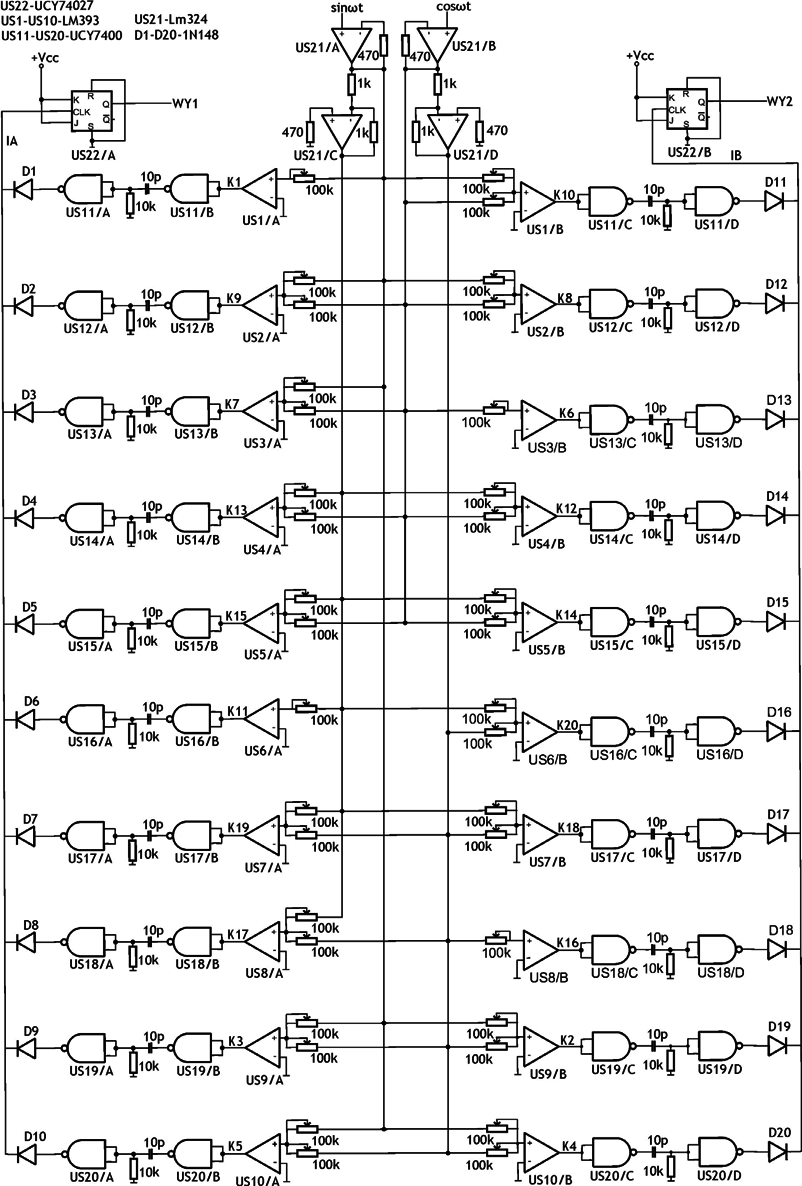

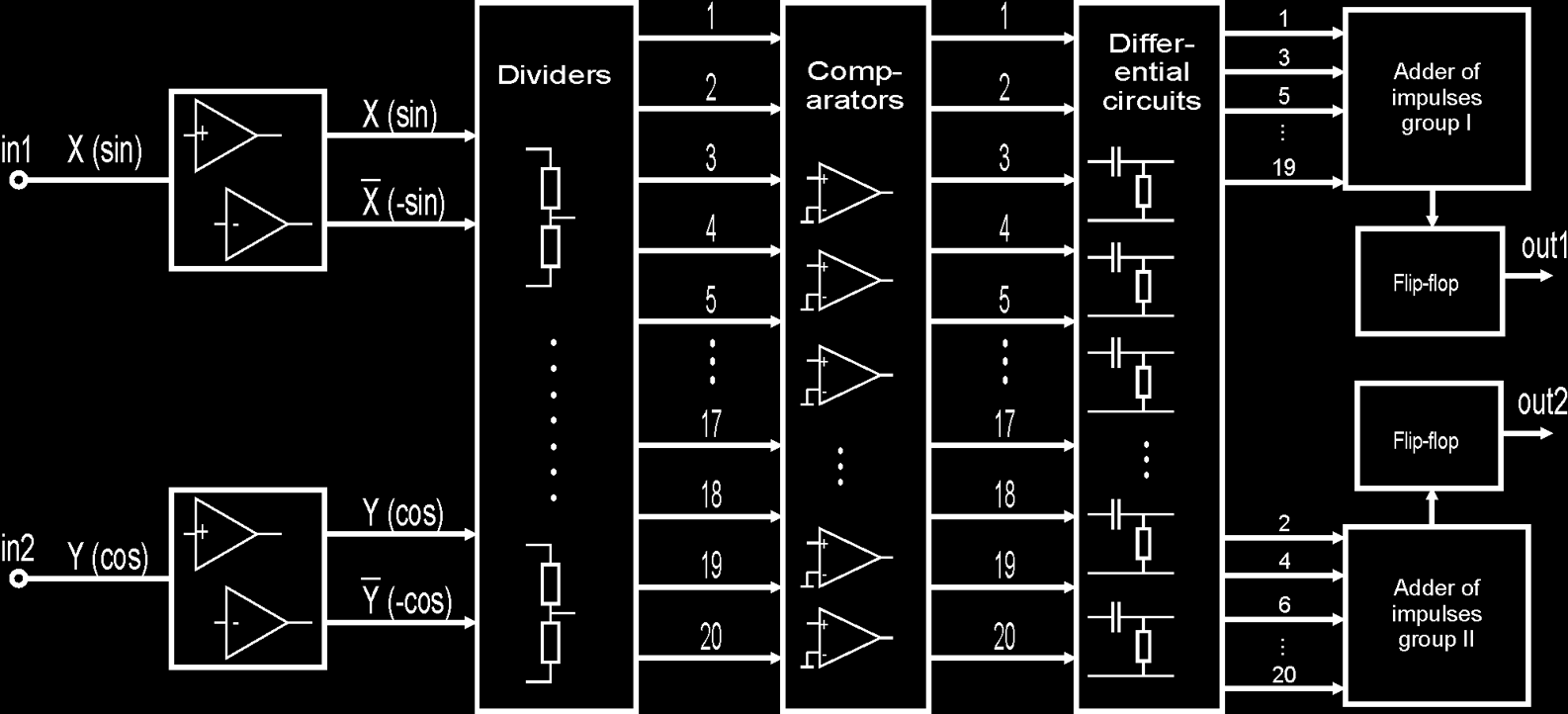

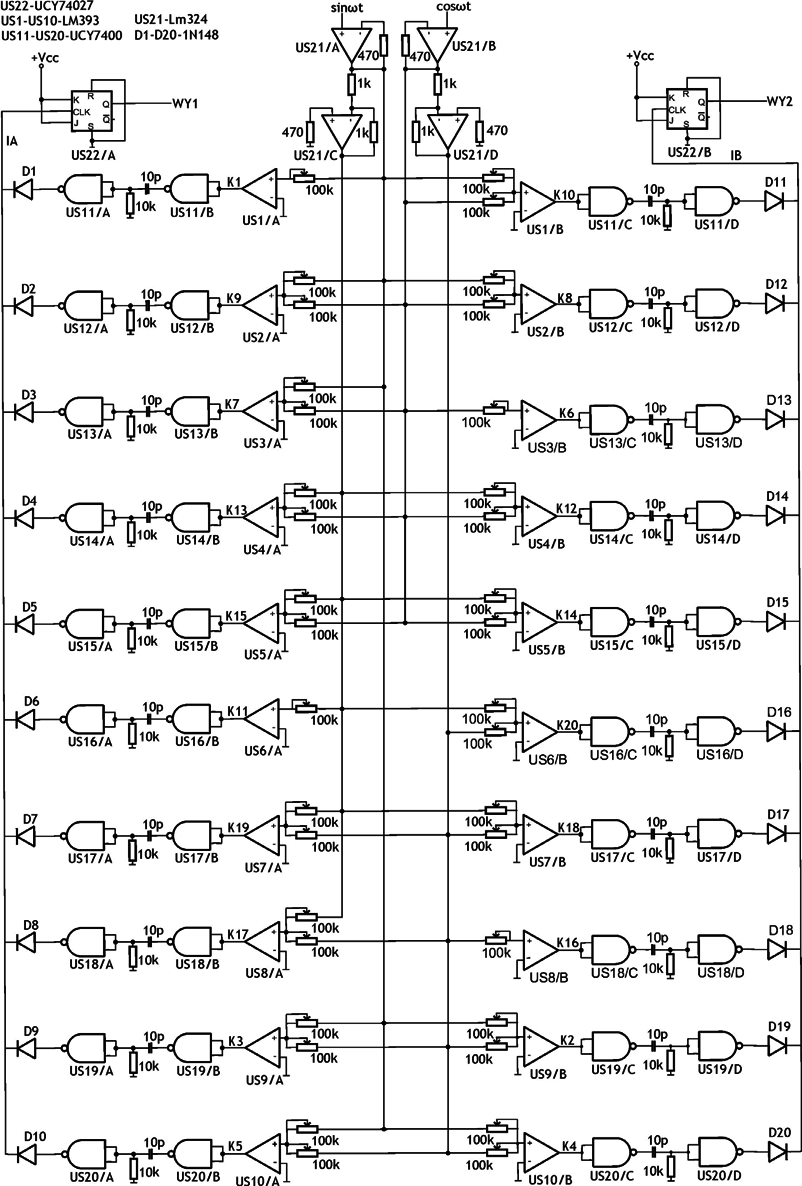

At the first stage of the method, signals are amplified and reversed producing four signals: sin,

cos, -sin, -cos, afterwards two appropriate of them get interpolated. This creates twenty

sinusoidal functions shift one from another by 18º. The principle of choosing input signals to

dividers for individual parts of period presents fig.7. It is essential for the signals selected for

interpolation to always have opposite signs in the period quarter that is of interest to us. For

quarter I (0° - 90°) sin and –cos signals are used, for quarter II (90°-180°) they are sin and cos,

for quarter III (180°-270°) the signals are -sin and cos, whereas for quarter IV (270°-360°), they

are -sin and -cos. The signals get to twenty resistance dividers, the values of which are selected

in such a way so that twenty sinusoidal waveforms are generated at their outputs. The

waveforms are shifted with respect to each other by an assumed angle, which in the method

presented amounts to 18°. For so assumed phase shift, for angles 0°, 90º, 180°,270º interpolation

does not occur and the signals -sin, cos, sin, -cos are selected for further processing.

Fig. 7. Selection of signals to interpolation for following parts of period of input signal

Fig. 8. The block diagram of the system of interpolation and digitalization of transducer signals

Methods and Devices of Processing Signals of Optoelectronic Position Transducers

359

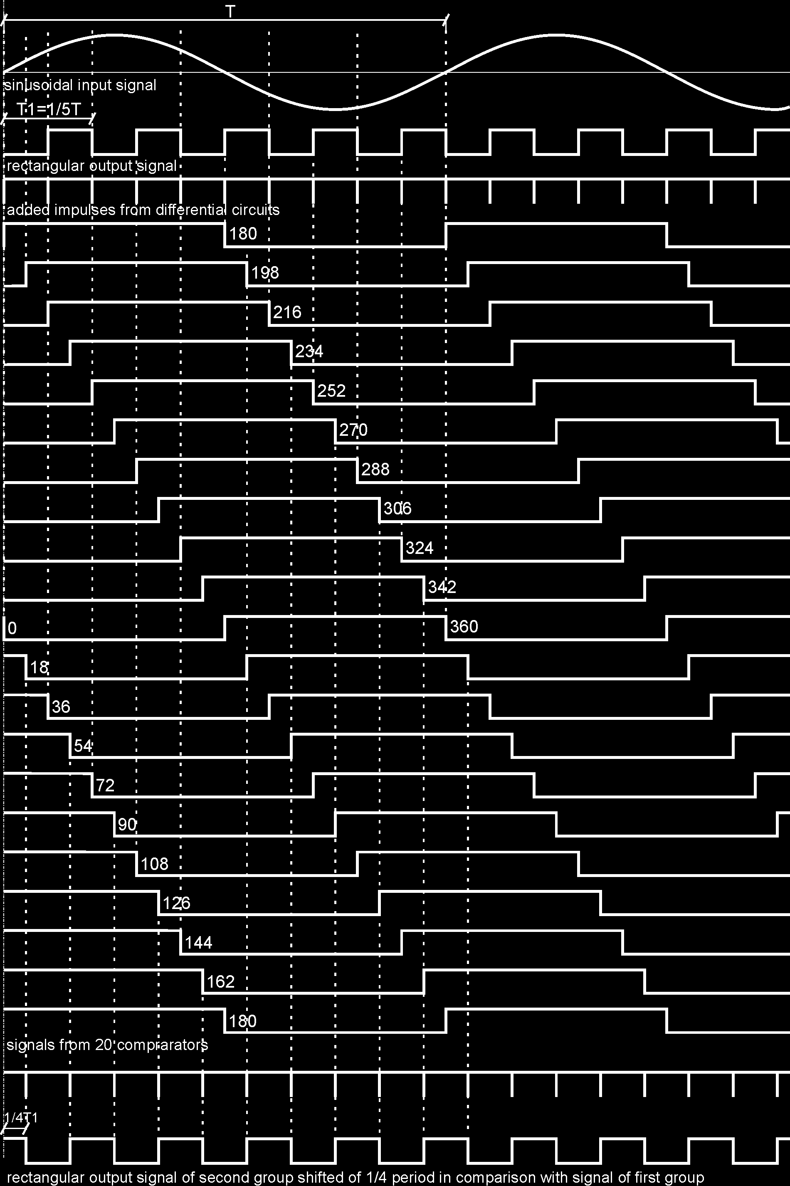

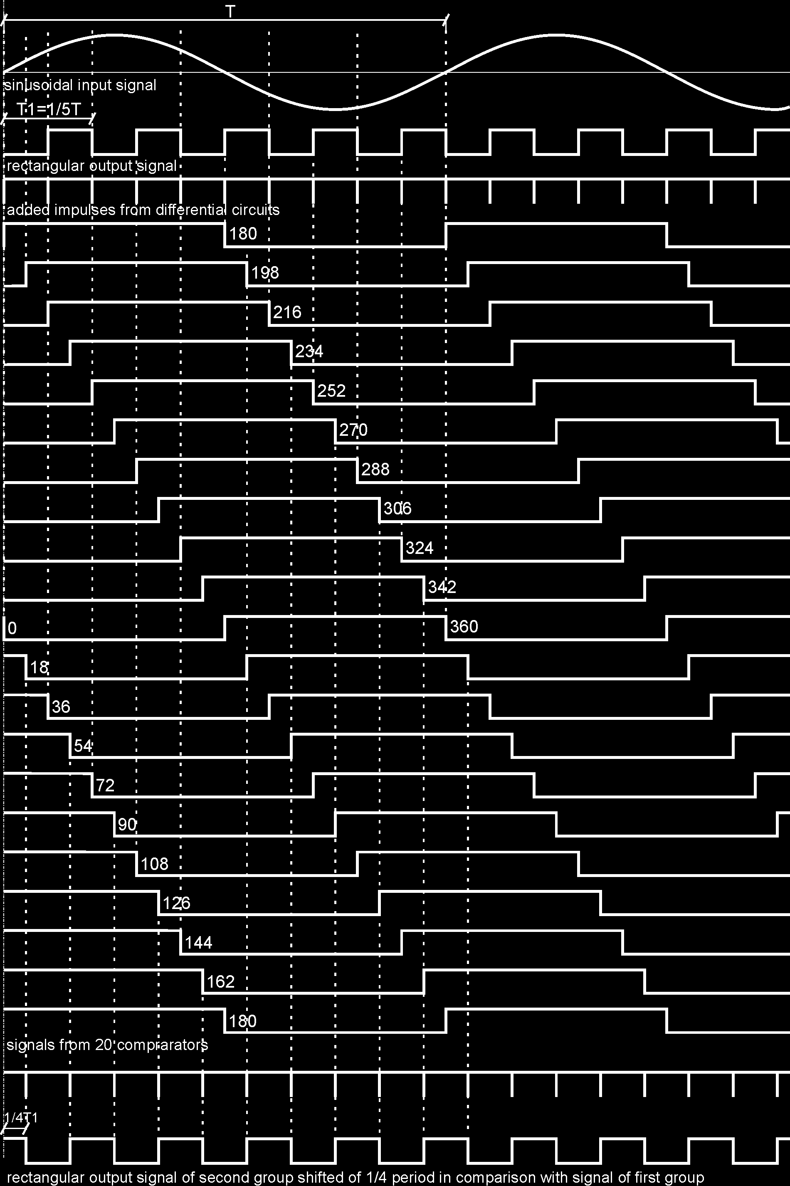

Fig. 9. Time functions of digital part of signals after interpolation

360

Optoelectronic Devices and Properties

Fig. 10. Schematic diagram of interpolation the circuit and digitalization of transducer

signals

Methods and Devices of Processing Signals of Optoelectronic Position Transducers

361

Angle

α

0 18 36 54 72 90 108 126 144 162

[°]

sinα

0,000 0,309 0,588 0,809 0,951 1,000 0,951 0,809 0,588 0,309

cosα

1,000 0,951 0,809 0,588 0,309 0,000 -0,309 -0,588 -0,809 -0,951

R1 [kΩ]

_ 64,72 34,02 24,72 21,02 20,00 21,02 24,72 34,02 64,72

R2 [kΩ] 20,00 21,02 24,72 34,02 64,72

_ 64,72 34,02 24,72

21,02

Angle

α

180 198 216 234 252 270 288 306 324 342

[°]

sinα

0,000 -0,309 -0,588 -0,809 -0,951 -1,000 -0,951 -0,809 -0,588 -0,309

cosα

-1,000 -0,951 -0,809 -0,588 -0,309 0,000 0,309 0,588 0,809 0,951

R1 [kΩ]

_ 64,72 34,02 24,72 21,02 20,00 21,02 24,72 34,02 64,72

R2 [kΩ] 20,00 21,02 24,72 34,02 64,72

_ 64,72 34,02 24,72

21,02

Table 1. Selection of resistor values for dividers from fig. 10

The generated signals are fed to one of twenty comparators which change their shapes making

them rectangular signals. In addition, the change in state takes place at the site of the input

signal passing zero. In this way twenty rectangular signals shifted with respect to each other

by 1/20 period (18°) are generated. The signals are divided into two groups in such a manner

that in each group each successive signal was shifted by 1/10 period with respect to the

previous one. Two groups of signals are formed, each containing ten signals shifted by 1/10

period within the group and by 1/20 period with respect to the other group (Fig.9, Fig.10).

The next stage consists in such differentiation of waveforms so that each run would yield

only one pulse in the period, i.e. one group will produce ten pulses dividing one period of

input reference signal into ten equal parts, on the assumption that the frequency of input

signals is constant. Pulses from two groups are summed to form two pulse waveforms of the

frequency that is five times higher than the input signal (Fig.8, Fig.10). They operate as clock

signals for JK triggers arranged in such as manner that each pulse of input clock signal

causes the change of state to the opposite one at the trigger output. As a result, two

symmetrical rectangular waveforms are created of the input frequency that is 5 times higher,

i.e. there is one input sinusoidal signal period to 5 periods of output rectangular signal. The

signals are shifted with respect to each other by 1/4 period and the displacement direction

depends on the direction of input signal shift, which is dependent on the transducer motion

direction (Pizoń et al., 1993) (Szcześniak, 2005)c (Szcześniak, 2005)f.

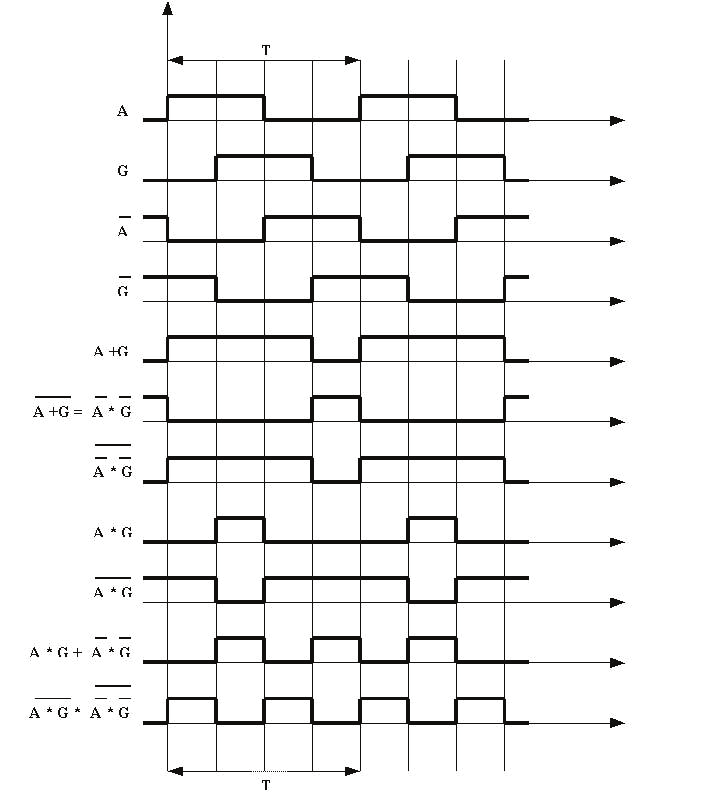

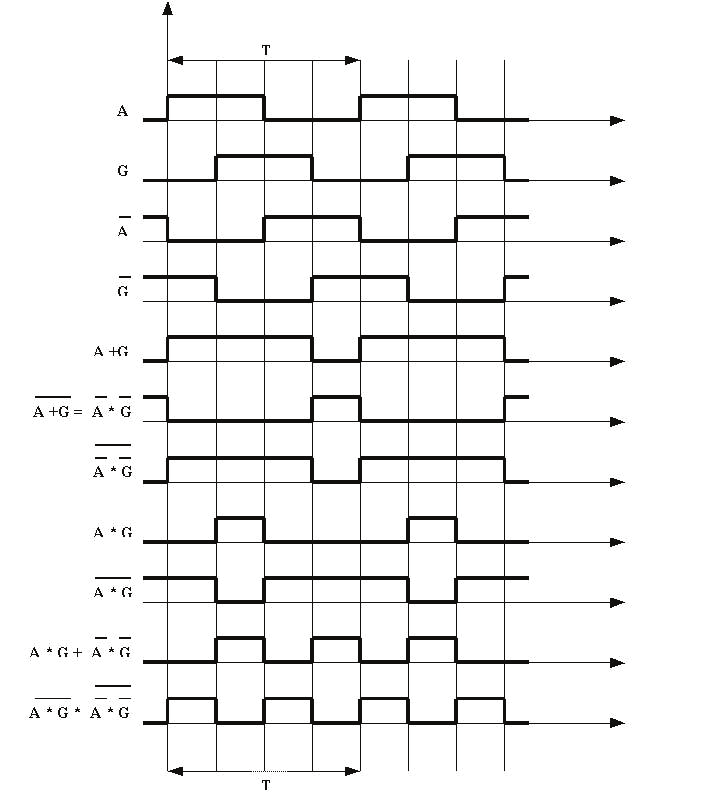

7. Method of optoelectronic transducer motion direction discrimination

based on logical functions of the transducer signals

In the previous chapter, the method of increasing the frequency of the measuring signal in

relation to the frequency resulting from quantization of position by the glass scale was

presented. The output signal is shaped as two rectangular signals shifted one from another

by ¼ period. These signals are used in processing systems which distinguish the motion

direction of a drive coupled with the transducer. Appropriate shaping of these signals

enables additional increase of processing accuracy of the transducer. (Pizoń et al., 1993)

(Szcześniak & Szcześniak, 2009)a (Szcześniak & Szcześniak, 2009)b (Szcześniak, 2006) a. The

method of optoelectronic transducer motion direction discrimination of the optoelectronic

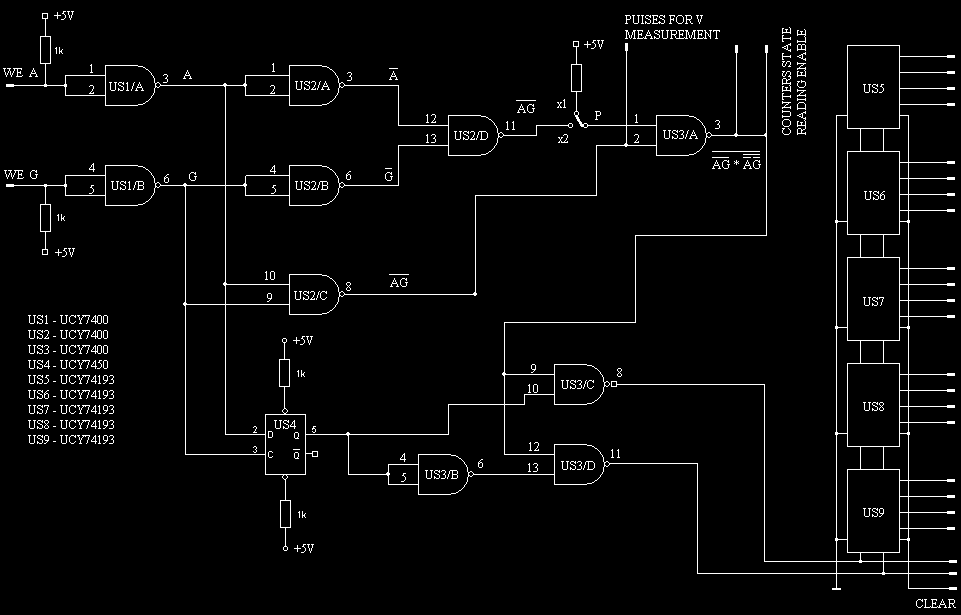

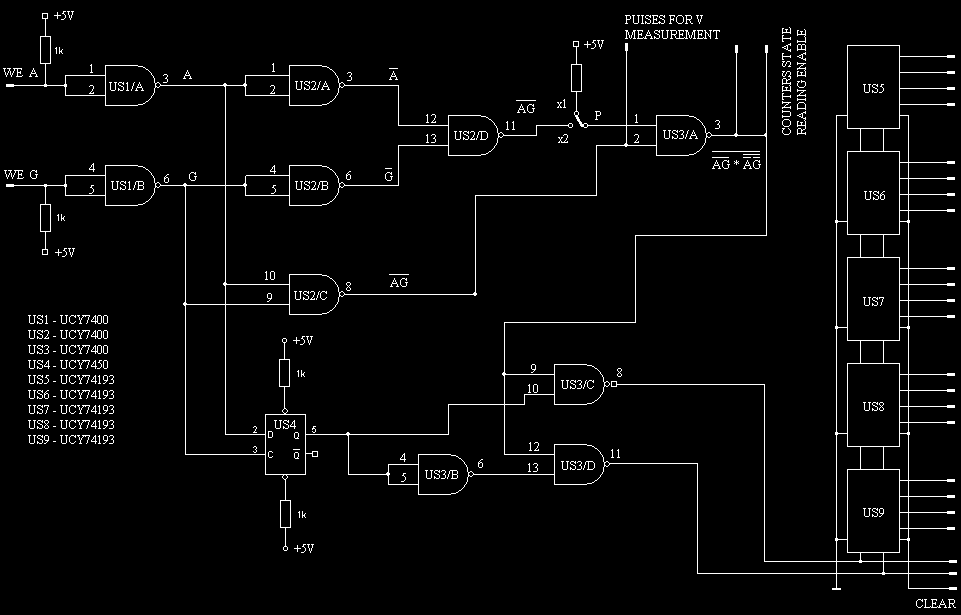

transducer is illustrated by time functions in fig.11. Circuit structure of optoelectronic

362

Optoelectronic Devices and Properties

transducer motion direction discrimination based on logical functions of transducer signals

presents fig.12. During the transducer operation the electric rectangular signals A, G, shifted

by quarter period are obtained on their two outputs (Fig.11, Fig.12). The task of the

presented electronic system is counting the adequately generated motion impulses and

distinguishing their sequence. The method is based on motion pulses generation on the base

of the sum of the signals A+G and on the base of their product AG, what is presented in Fig.

1. Making the sum of those pulses

WY = A + G + AG (8)

it is possible to generate, during the period T, 1 or 2 pulses, which are counted in the reverse

order.

Fig. 11. Method of optoelectronic transducer motion direction discrimination based on

logical functions of the transducer signals

Methods and Devices of Processing Signals of Optoelectronic Position Transducers

363

Fig. 12. System of optoelectronic transducer motion direction discrimination based on

logical functions of the transducer signals

The counting order is chosen dependently on the shift between the A and G signals, what is

set by the trigger. The G signal is delivered to the clock input and the A signal is delivered

to the D input of the trigger. Change of the G signal from "0" to "1", when A="1", sets the Q

trigger to "1". Counting to the right is then enabled. In the case when change of the G signal

appears at A="0", i.e. when the G signal is leading to the A signal (change of the motion

direction, the Q trigger changes its state and counting to the left is enabled. The system

enables the choice of measurement accuracy x1 or x2, dependently on the setting of the P

switch.

8. Method of optoelectronic transducer motion direction discrimination

based on logical functions of the transducer signals and motion pulses

generated in the RC circuits

In this method (Fig.13, Fig.14.), by summing