construction”,International Journalof Robotic Resarch, Vol. 5, pp. 157-182.

Griffis, M., and Duffy, J., ”A Forward Displacement Analysis of a Class of Stewart

Platforms,” Trans. ASME Journal of Mechanisms, Transmissions, and A utomation

in Design, Vol. 6, No. 6, June 1989, pp. 703-720.

Affi Z., Romdhane L. and Maalej A., 2004. Dimensional synthesis of a 3-translational-DOF

in-parallel manipulator for a desired workspace. European Journal of Mechanics -

A/Solids, Vol 23, Issue 2, pp 311-324.

Clavel, R. 1986. Une nouvelle structure de manipulation parallèle pour la robotique légère.

R.A.I.R.O. APII, Vol 23, N° 6.

Vischer P. and Clavel R. 1998,”Kinematic Calibration of the Parallel Delta Robot”, Robotica,

16, pp. 207-218.

M. Stock and K. Miller 2003, ”Optimal Design of Spatial Parallel Manipulators: Application

to linear Delta Robot”, ASME Journal of Mechanical Design, Vol. 125, pp 292–301.

Hervé J. M. 1995, “Design of Parallel Manipulators via Displacement Group”, Proceedings

of the 9th World Congress on the Theory of Machines and Mechanisms. pp. 2079-

2082.

Hervé, J. M., Sparacino F. 1991. Structural synthesis of parallel robots generating spatial

translation. 5th Int.Conf. On Adv. Robotics, IEEE n°91TH0367-4, Vol. 1, pp 808-813.

Romdhane, L. 1999, Design and analysis of a hybrid serial-parallel manipulator. Mechanism

and Machine Theory, Vol. 34, Issue 7, pp 1037-1055.

Romdhane, L., Affi Z., Fayet M., 2002. Design and singularity analysis of a 3 translational-

DOF in-parallel manipulator. ASME Journal of Mechanical Design, Vol. 124, pp

419–426.

A. Tremblain and L. Baron 1999, ”Geomatrical synthesis of parallel manipulators of star-like

topology with a geometric algorithm”, IEEE International Conference on Robotics

and Automation, Detroit, MI.

Tsai L-W 1996,“Kinematics of three-dof platform with three extensible limbs” In J. Lenarcic

V. Parenti-Castelli, editor, Recent Advances in Robot Kinematics, pp 401 410,

Kluwer.

C. Gosselin,1990, ”Determination of the workspace of 6-dof parallel manipulators”, ASME

Journal of Mechanical Design, Vol. 112, pp. 331-336.

Advanced Synthesis of the DELTA Parallel Robot for a Specified Workspace

223

L. Romdhane,1994, ”Orientation workspace of fully parallel mechanisms”, Eur. J. of

Mechanics Vol. 13, pp. 541-553.

R. Boudreau and C. M. Gosselin 1999, ”The synthesis of planar parallel manipulators with a

genetic algorithm”, ASME Journal of Mechanical Design, Vol 121, pp 533-537.

R. Boudreau and C. M. Gosselin 2001, ”La synthèse d’une plate forme de Gough-Stewart

pour un espace de travail atteignable prescrit”, Mech. Mach. Theory 36 (2001) 327-

342.

Kosinska, A, Galicki, M. and Kedzior, K. 2003,”Design and optimization of parameters of

Delta-4 Parallel Manipulator for a Given Workspace”, Journal of Robotic Systems

20 (9), pp 539-548.

J. A. Snyman and A. M. Hay 2005, ”Optimal synthesis for a continuos prescribed dexterity

interval of 3-DOF parallel planar manipulator for different prescribed output

workspaces”, Proceeding of CK2005, 12th International Workshop on

Computational Kinematics Cassino May 4-6.

M. Gallant and R. Boudreau 2002, ”The synthesis of planar parammel manipulators with

prismatic joints for an optimal, singularity-free workspace”, Journal of Robotic

Systems 19 (1), pp 13-24.

F. Pierrot, C. Reynau and A. Fourier 1990, ”DELTA : a simple and efficient parallel robot”,

Robotica Vol. 8, pp 105-109.

Goudali, A. 1995. Contribution à l’étude d’un nouveau robot Parallèle 2- Delta à six degrés

de liberté avec découplage. Thèse de doctorat Génie Mécanique L.M.S. Poitiers.

France.

J.P. Lallemand, A. Goudali and S. Zeghloul, ”The 6 - D.o.f. 2 - Delta parallel robot” ,

Robotica Journal, Vol. 15, pp 407-416, 1997.

Goldberg, D.E., 1994, Genetic Algorithms in Search, Optimization, and Machine Learning,

Addison-Wesley Publishing, Reading, MA.

Chipperfield A., Fleming P., Pohlheim H. and Fonseca C. 1994, ”Genetic

AlgorithmTOOLBOX user’s Guide” Department of automatic control and systems

engineering university of Sheffield version (v 1.2)

J.A. Lozano , P. Larranaga, M. Grana, F.X. Albizuri 1999, Genetic algorithms: bridging the

convergence gap, Theoretical Computer Science Vol. 229, pp 11-22.

R. Chelouah, P. Siarry 2000, A continuous genetic algorithm designed for the global

optimization of multimodal functions, Journal of Heuristics Vol. 6, pp. 191-213.

Schmitt L. M. 2001, Fundamental Study Theory of genetic algorithms, Theoretical Computer

science n°259 pp 1-61.

Laine, R., Zeghloul, S., Ramirez, G., 2002, A Method based on a Genetic Algorithm for the

Optimal Design of Serial Manipulators, Int. Symp. Rob. and Aut., pp. 15-20, Toluca,

Mexique.

M.A. Laribi, A. Mlika, L. Romdhane and S. Zeghloul, 2004,”A Combined Genetic Algorithm-

Fuzzy Logic Method (GA-FL) in Mechanisms Synthesis”, Mech. Mach. Theory 39,

pp. 717-735.

Coxeter, H. S. M.1969, ”Introduction to Geometry”, 2nd ed. New York: Wiley.

Alden H. Wright, 1991,”Genetic algorithms for real parameter optimization, Foundations of

Genetic Algorithms”, (edited by Gregory J. E. Rawlins), Morgan Kaufman, pp. 205-

218.

Steiner, J., 1826 ,”Einige geometrische Betrachtungen.” J. reine angew. Math. 1, pp. 161-184.

224

Parallel Manipulators, Towards New Applications

A Appendix

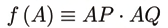

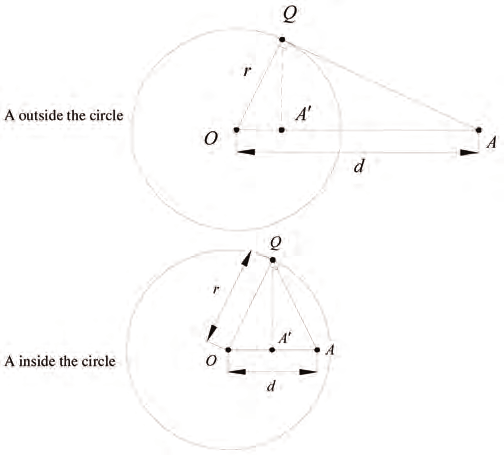

The power of a fixed point A (see Figure 17) with respect to a circle of radius r and center O

is defined by the product

Where, P and Q are the intersections of a line through A with the circle. The term ”power”

was first used in this way by Jacob Steiner [33,31]. f ( A) is independent of the choice of the

line APQ.

Now consider a point A (see Figure 17) not necessarily on the circumference of the circle. If d

= OA is the distance between A and the circle’s center O with equation f ( x, y) = x2 + y2 − r2 =

0, then the power of the point A relative to the circle is givn by :

Fig. 17: The power of the point.

If A is outside the circle, its power is positive and it is equal to the square of the length of the

segment AQ from A to the tangent Q to the circle through A,

If A is inside the circle, then the power is negative.

11

Size-adapted Parallel and Hybrid Parallel

Robots for Sensor Guided Micro Assembly

Kerstin Schöttler, Annika Raatz and Jürgen Hesselbach

Technische Universität Braunschweig, Institute of Machine Tools and Production

Technology (IWF), Langer Kamp 19 B, D-38106 Braunschweig

Germany

1. Introduction

Miniaturized products and components are part of today’s daily life. The comfort and

security of automobiles is increased by use of micro sensors and actuators. Electronic

devices, such as mobile phones and MP3-players, have reached very small sizes and

miniaturized medical instruments facilitate endoscopic surgery.

Due to the advantages of micro technological solutions, such as small dimensions and low

weight, Micro Systems Technology (MST) is worldwide considered a key technology of the

21st century. The new NEXUS market analysis forecasts a yearly growth of the world

markets of 16% for products based on MST (Wicht & Bouchaud, 2005).

Miniaturization and simultaneous function integration are leading to increased

requirements regarding production technology as a result of scaling effects, technical and

assembly related problems (van Brussel et al., 2000). For MST products, micro assembly

uncertainties in the range of a few micrometers or even less than one micrometer are

required.

1.1 Approaches to meet the requirements for micro assembly

At present industrial applications for micro assembly predominantly incorporate systems

which were originally developed for 2D chip assembly in semi-conductor back-end

production. They can be classified into three groups according to their attainable assembly

uncertainty. Most of the positioning units of the first class are pick-and-place machines

based on Cartesian axes with uncertainties between 30 µm and 60 μm at 3σ. The second

group, die-bonding machines, reaches pick-and-place uncertainties of 10 µm to 12 μm at 3σ

by means of high-precision linear drives, high-resolution camera systems as well as systems

for controlling and compensating for influences caused by changing temperatures. Ultra-

precision die-bonders form the third class. They can be regarded as special machines for

specific applications which were developed for the assembly of micro-optical components,

optical fibres and especially for flip-chip assembly. They reach assembly or pick-and-place

uncertainties of about 1 μm at 3σ. These low uncertainties can only be achieved with the

help of special camera systems and positioning strategies. At present, these assembly

uncertainties are always tied to a highly customized design of the assembly system adjusted

226

Parallel Manipulators, Towards New Applications

to the requirements of the products. This way the assembly uncertainties described are

reached at the expense of a very low flexibility (Raatz & Hesselbach, 2007).

For the design of micro assembly systems it is necessary to gain a high product flexibility of

the assembly units. Solutions that provide enough flexibility to reconfigure the system

design need to be found. Here, modularity is the key when striving for high flexibility of the

number of quantities, product variants and manufacturing base. The precision robot

represents the central component within the assembly system. Some fundamental

techniques to lower the uncertainty of the precision robot and the assembly system are

choosing an adequate kinematic structure, developing size adapted handling devices,

integrating ultra-precision machine elements and/or using sensor guidance (Fig. 1).

Increased accuracy

Precision

Kinematic

Size adapted

Ultra-precision

robot

structure

handling devices

machine elements

Assembly

Sensor

Precise peripherie

...

system

guidance

(gripper, feeder)

Fig. 1. Approaches to meet the requirements of accuracy (Raatz & Hesselbach, 2007)

1.2 Kinematic structures

Robots can be classified in terms of their kinematic structure into serial, parallel and hybrid

(serial/parallel) robots. Most industrial robots are based on a serial structure between the

frame and the working platform. All joints of open kinematic chains have a single degree of

freedom (DOF) and are active, i.e. they are actuated. The serial structure offers in principle a

large workspace in relation to the size of the robot as well as a high orientation range. The

relatively large moved masses are a disadvantage of serial structures regarding the

dynamics and accuracies of the robot, since each drive must be moved along with the entire

kinematic chain. In micro assembly, large moved masses lead to massive construction of the

frames and the robot links related to the size of the assembled parts.

Parallel robots are based on closed kinematic chains, i.e. they have several guiding chains

between the base frame and the working platform, which provide a high structural stiffness.

It is possible to install all drives in a fixed frame or at least to locate them nearby the frame,

which results in low inertia. Drive positioning errors or tolerances in the legs are not

necessarily added. Usually they partially compensate each other and only affect the

positioning uncertainty of the end effector to a small extent.

Parallel robots are well suited for highly precise handling operations, due to their high

structural stiffness with low moved masses at the same time. Compared to serial robots, the

miniaturization of a parallel robot is much easier because all joints are passive. In addition

the passive joints offer the potential for integrating flexure hinges as ultra-precision machine

elements. The small workspace compared to the robot dimensions does not become severe

in micro assembly tasks due to the size of the objects.

Combining a parallel structure with a serial structure the limited and position dependent

mobility of the end effector can be overcome. For example by integrating a serial rotational

axis into the working platform of a parallel robot, the end effector can be very well oriented.

Size-adapted Parallel and Hybrid Parallel Robots for Sensor Guided Micro Assembly

227

1.3 Robots for micro assembly

A number of commercial robot manufacturers and many research institutions are

developing robots which have sufficient positioning uncertainties for micro assembly tasks.

Serial, parallel and hybrid robot structures are used. Most serial robots for micro assembly

use a Cartesian structure. Often they incorporate modular precision linear axes. In nearly all

cases, direct measuring systems are used in order to rule out inaccuracies due to mechanical

play. The repeatability of those linear axes lies typically between 0.1 µm and 1 µm. Some

manufacturers and researchers claim that robots build with these axes reach an overall

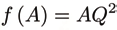

repeatability of 1 µm. A typical exponent of this class of robots is the Sysmelec Autoplace

411 (Fig. 2) (Hesselbach et al., 2005). Another solution for micro assembly robots are

conventional Scara robots in combination with redundant high-precision axes in order to

reach a high resolution. This approach is always combined with additional sensors to

achieve a good repeatability (Höhn, 2001).

Fig. 2. Serial robot Sysmelec Autoplace 411 with Cartesian structure

The development of size-adapted robots is another solution of robots for micro assembly.

Saving costs is only possible by reducing the footprint of an assembly system due to the

demand of a clean room environment for the production of MST products. In recent years,

the reduction of size and costs of micro production systems has been widely discussed in

various papers. Most of these concepts relate to one of the two general groups explained in

the following.

The first group consists of piezo driven, small walking micro robots and handling machines.

These autonomous robots are suitable for positioning small objects such as the MINIMAN

of (Fatikow, 2000), a handling device for samples in a scanning electron microscope. On the

one hand, these micro robots are very promising for new trends such as nano assembly. By

using autonomous robots, difficulties occur regarding the coordination and interaction of

these robots, movement on rough surfaces and energy supply.

The second group describes cost-efficient, size-adapted handling devices, which fill the gap

between piezo driven, small walking micro robots and conventional robots. A possible

solution for this strategy is to determine the highest degree of miniaturization of

conventional robot technology, using innovative, miniaturized machine parts. With these

228

Parallel Manipulators, Towards New Applications

size-adapted handling devices, in the range of several centimeters to a few decimeters,

easily scalable and highly flexible production technology can be designed. Examples of size-

adapted handling devices are the parallel robot structures Delta3 and Sigma 6 from (Clavel

et al., 2005) and the pocket delta from (Coudourey et al., 2006).

This chapter presents a description of four size-adapted robot mechanisms based on parallel

and hybrid structures. For three robot mechanisms, the structures are first designed with

conventional joints and replaced by flexure hinges as ultra-precision machine element later

on.

Furthermore, sensor guided assembly processes of hybrid micro systems are explained on

the basis of one robot structure. Thus, the integration of sensor information into the robot

control as well as the relative sensor guidance applied in the system will be presented. The

positioning uncertainty and the assembly uncertainty of the process are described by means

of an example of an assembly process.

2. Size-adapted parallel and hybrid robot structures

Various size-adapted parallel, parallel hybrid and serial hybrid robots for precision

assembly were developed at the IWF. The main objective to develop size-adapted robot

structures was to adapt the size of the robot cell to the size of the products. At the same time

a good repeatability for highly precise micro assembly processes should be reached through

the development of parallel and hybrid robot structures.

First, a functional model of a planar robot micaboe (see section 2.2) with a parallel structure

and 3 DOF for movement in the x-y plane and 1 DOF as a serial lifting table for movement

in z-direction was implemented. Second, a spatial parallel hybrid robot structure micaboh

(see section 2.3) with 6 DOF was designed. Then, a spatial parallel robot structure, Triglide

(see section 2.4), based on a parallel structure with 3 DOF and one serial rotational axis was

realized.

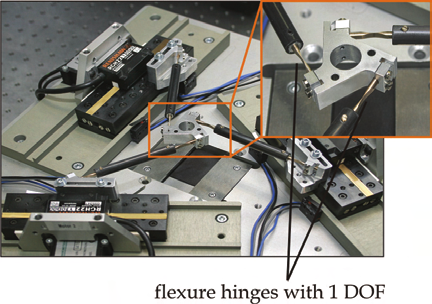

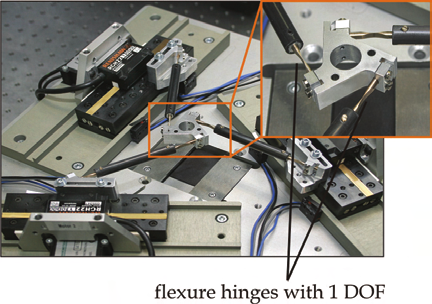

These three robots were enhanced by integrating flexure hinges (see section 2.1) as ultra-

precision machine elements and named micaboes, micabohs and Triglides. With this machine

elements, the conventional joints of the robot structures are replaced.

Based on the experiences with the above mentioned robot structures, the robot micabof,

which provides 4 DOF for part handling and, as an advanced structure, the micabof2 (see

section 2.5), which provides 4 DOF for part handling and 1 additional DOF for focusing a

vision sensor, were developed as planar serial hybrid robot structures.

2.1 Pseudo-elastic flexure hinges

One way to increase the accuracy of assembly systems is to enhance the positioning

accuracy of the robot itself. Typical problems of parallel structures are the high number of

joints and joints with more than one DOF. Backlash, friction and slip-stick effects in

conventional joints often decrease the overall precision of the robot. As a result of the

natural lack of the above mentioned disadvantages in flexure hinges, replacing conventional

joints by flexure hinges seems to be a promising way to increase the accuracy of robots.

Since flexure hinges gain their mobility exclusively from a deformation of matter, the

attainable angle of rotation is limited. In order to achieve high life cycles of the hinges, the

deformation should remain in the elastic part since plastic deformation normally induces

defects in the material leading to an earlier crack failure (Hesselbach et al., 2004b).

Size-adapted Parallel and Hybrid Parallel Robots for Sensor Guided Micro Assembly

229

The developed flexure hinges consist of a pseudo-elastic shape memory alloy (SMA). This

material offers larger reversible strains than other materials, e.g. spring steel or

thermoplastics, which are commonly used for flexure hinges. Due to the large reversible

strains of SMA, deflections of the hinges of ±30° are possible. This approach offers the

potential to design robots with high accuracy and resolution and with a sufficiently large

workspace for micro assembly tasks (Hesselbach et al., 2004a).

SMA exists in austenite and martensite phases, depending on the temperature or the

applied stress. The temperature and stress values for stable phases mainly depend on the

basic material, their different alloy contents and the thermo-mechanical treatment of the

material. The thermally induced phase transformation of SMA (one way effect) is typically

used in applications in which the SMA device is used as an actuator. We use the stress

induced phase transformation which offers large reversible strains (super-elasticity).

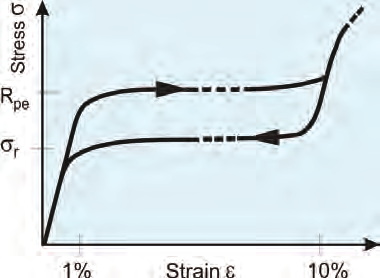

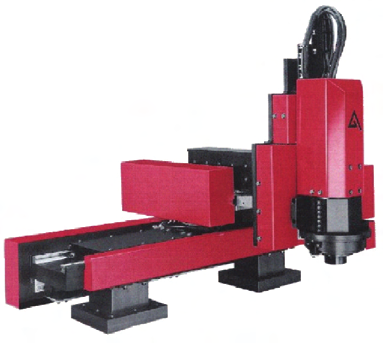

Figure 3 shows a stress-strain diagram of pseudo-elastic SMA loaded with uniaxial tensile

stress. In its initial condition, the material is in its austenitic phase at room temperature.

First, it deforms linear elastic under load. With increasing loads a stress-induced

transformation of austenite into martensite is initiated at the pseudo-yield stress Rpe. The

phase transformation is accompanied by large pseudo-elastic strains εpe with nearly constant

stresses. The pseudo-elastic strain is reverted at a lower stress σr with a stress hysteresis.

Since pseudo-elastic strains are reversible, the specimen completely recovers to its

undeformed shape. These strains are often called pseudo-elastic because the reversible

deformation is caused by a reversible phase transformation and not only due to a translation

of atoms out of their former equilibrium position.

Fig. 3. Stress-strain diagram of shape memory alloy

A pseudo-elastic CuAlNiFe single crystal SMA is used for the design of flexure hinges

because of its superior machinability and extremely large reversible strains up to 17%. The

uniaxial stress-strain diagram of a CuAlNiFe single crystal has two pseudo-elastic stress

plateaus, differing slightly from the example shown in Figure 3, but equivalent in principle.

The first plateau, which is the area of interest, has a yield stress of about Rpe=200 N/mm²

and reversible strains of ε=10%.

A variety of different geometries of flexure hinges are proposed in the literature. They are

designed in monolithic or hybrid processes allowing for up to 3 degrees of freedom (DOF)

(Smith, 2000), (Paros & Weisbord, 1965). When designing flexure hinges for robots

optimisation criteria are high accuracy and a large workspace of the robot. For the three

230

Parallel Manipulators, Towards New Applications

robots micaboes, micabohs and Triglides (described in section 2.2, 2.3 and 2.4) pseudo-elastic

flexure notch hinges with R=15 mm and h=0.15 mm are used. These geometrical dimensions

are an optimum between small kinematic deviations compared to the kinematics of an ideal

rotational joint and small occurring strains. The pseudo-elastic material can be modelled

with a material model by Prandtl-Reuss if the deflection curve is calculated analytically

(Howell & Midha, 1995), (Hesselbach & Raatz, 2000) or with a multilinear elastic material

model using the FEM tool ANSYS. With the chosen geometry and geometrical dimensions

maximal strains are ε=2.1% at deflections of 20° and ε=4.2% at 30°.

2.2 Planar parallel robot structures micaboe and micaboes with 3 DOF and one serial z-

axis

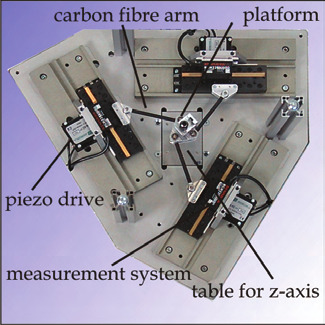

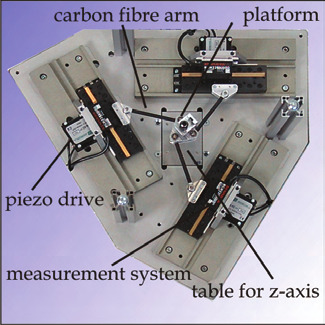

The planar parallel robot structure micaboe (Fig. 4 left) provides 3 DOF. Three linear drives

move the platform and the gripper with three guiding chains in x-y-direction and enable a

rotation ϕ around the z-axis. The movement in the direction of the z-axis is performed by an

additional elevation platform. The robot is driven by three piezoelectric stick-slip drives

with a smallest step size of 5 nm and is equipped with linear encoders with a resolution of

0.1 µm. First, the pa