parts can be measured because the gripper covers half of the guide and the stator (see Fig. 12

Size-adapted Parallel and Hybrid Parallel Robots for Sensor Guided Micro Assembly

241

right). Therefore, the 3D vision sensor observes only the visible sides of the assembled parts.

This means that the measured positioning error and the resulting positioning uncertainty

are only determined by the visible part side. After the process, both ends of the assembly

group can be inspected and the overall assembly deviation can be measured. The assembly

uncertainty is calculated from the deviations. This value is comprised of the overall errors

during the assembly of the micro system.

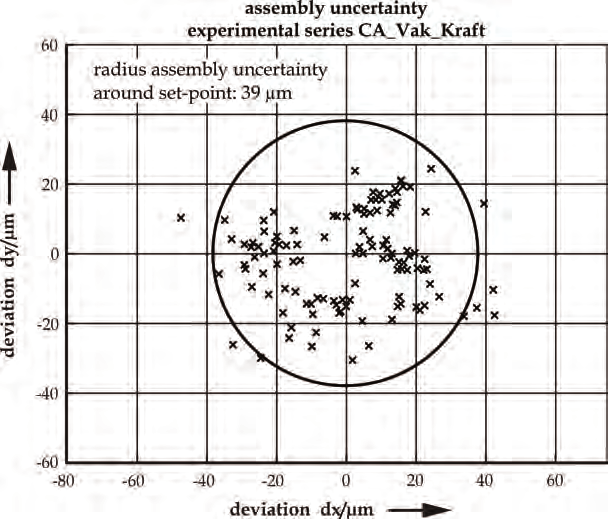

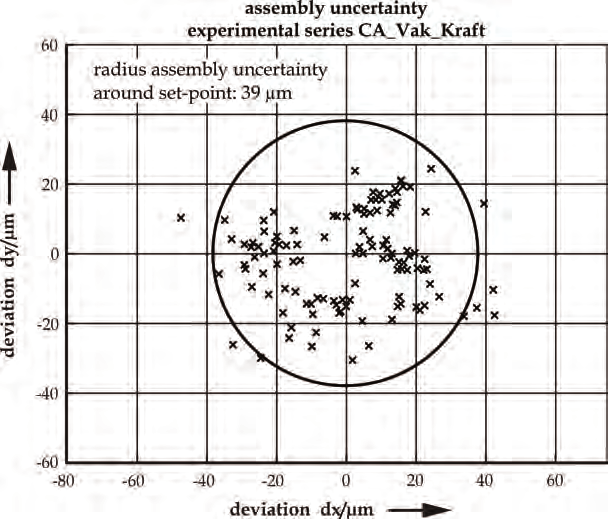

An assembly uncertainty of 38 µm and a positioning uncertainty of 0.82 µm are reached for

the assembly process. The difference between assembly uncertainty and positioning

uncertainty is a result of the relatively long part length of 10.66 mm. A small angular

deviation causes a positioning error (in xy-direction). This error is larger at the side of the

part which is invisible during the positioning process than the error on the visible side. With

a greater part length, this positioning error will be higher than with smaller parts.

Furthermore, deviations occurring during the bonding process cause an increased assembly

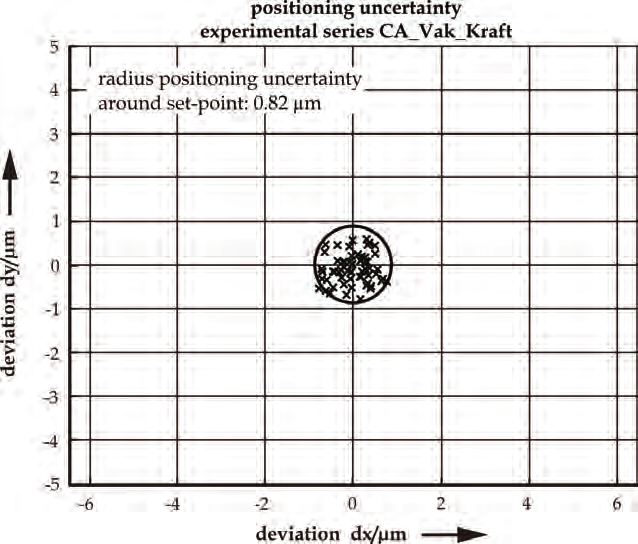

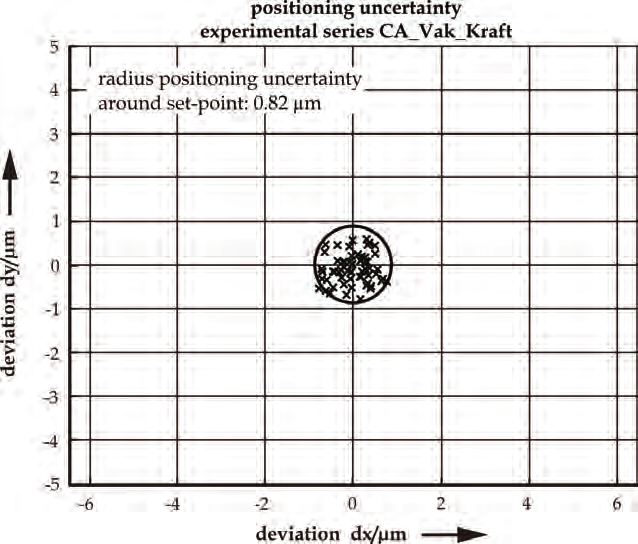

error. Figure 14 shows the positioning uncertainty and figure 15 the assembly uncertainty of

the assembled groups. The circles in the diagrams show the radius of the uncertainties.

Fig. 14. Reached positioning uncertainty

In another assembly task, assembly uncertainties of 25 µm were reached with another

design of the assembly group. Therefore, the distance between the positioning marks has

been enlarged. A positioning uncertainty and a limit value of 0.5 µm was reached with this

arrangement of the positioning marks. This demonstrates the potential for further

improvement of the assembly uncertainty.

242

Parallel Manipulators, Towards New Applications

Fig. 15. Reached assembly uncertainty

4. Conclusion

Micro assembly tasks demand low assembly uncertainties in the range of a few

micrometers. This request results from the small part sizes in the production of MST

components and the resulting small valid tolerances. Since precision robots represent the

central component of an assembly system, an appropriate kinematic structure is crucial.

These kinematic structures can be serial, parallel or hybrid (serial/parallel). Although serial

structures can be used for micro assembly, they have large moved masses and need a

massive construction of the frame and robot links to obtain an appropriate repeatability.

Therefore, some size-adapted parallel and hybrid parallel robot structures were presented in

the previous sections. Very good repeatabilities were reached with the presented robots due

to the chosen structures, the miniaturized design and the use of flexure hinges as ultra-

precision machine components.

Besides the precision robot, most assembly tasks require the use of additional sensors with

high resolutions and measurement accuracies to reach a low assembly uncertainty.

Therefore, optical and/or force sensors are used for sensor guided micro assembly

processes.

The terms “absolute sensor guidance” and “relative sensor guidance” were introduced. Both

methods offer an enhancement of the accuracy within micro assembly processes. The

“relative sensor guidance” promises a lower positioning and assembly uncertainty because

of the user defined number of position correction loops. Therefore, relative sensor guidance

was used in the presented example for micro assembly.

Size-adapted Parallel and Hybrid Parallel Robots for Sensor Guided Micro Assembly

243

With the use of relative sensor guidance, positioning uncertainties below 0.5 µm can be

reached. The assembly uncertainty has to be further improved to fulfil the demand for

assembly uncertainties in the range of a few micrometers. Therefore, the design of the

product and positioning marks as well as the gripping and joining technology has to be

examined in future developments.

5. References

Berndt, M. (2007). Photogrammetrischer 3D-Bildsensor für die automatisierte Mikromontage,

Schriftenreihe des Institutes für Produktionsmesstechnik, No. 3, Shaker Verlag,

ISBN 978-3-8322-6768-1, Aachen

van Brussel, H. ; Peirs, J. ; Delchambre, A. ; Reinhart, G. ; Roth, N. ; Weck, M. & Zussman, E.

(2000). Assembly of Microsystems, Annals of CIRP, Vol. 49, No. 2, pp. 451-472

Clavel, R.; Helmer, P.; Niaritsiry, T.; Rossopoulos, S.; Verettas, I. (2005). High Precision

Parallel Robots for Micro-Factory Applications, Robotic Systems for Handling and

Assembly - Proc. of 2nd International Colloquium of the Collaborative Research Center 562,

Fortschritte in der Robotik Band 9, Shaker Verlag, ISBN 3-832-3866-2, Aachen,

pp. 285-296

Coudourey, A.; Perroud, S.; Mussard, Y. (2006). Miniature Reconfigurable Assembly Line

for Small Products, Proc. Third International Precision Assembly Seminar (IPAS'2006),

Springer Verlag, ISBN 0-387-31276-5, Berlin, pp. 193-200

DIN ISO 230-2 (2000). Prüfregeln für Werkzeugmaschinen, Teil 2: Bestimmung der

Positionierunsicherheit und der Wiederholpräzision der Positionierung von

numerisch gesteuerten Achsen, Beuth Verlag, Berlin

EN ISO 9283 (1999). Industrieroboter: Leistungskenngrößen und zugehörige Prüfmethoden.

Beuth Verlag, Berlin

Fatikow, S. (2000). Miniman. In: Mikroroboter und Mikromontage, p. 277, Teubner Verlag,

ISBN 3-519-06264-X, Stuttgart – Leipzig

Hesselbach, J.; Plitea, N. ; Thoben, R. (1997). Advanced technologies for micro assembly,

Proc. of SPIE, Vol. 3202, pp. 178-190

Hesselbach, J. ; Raatz, A. (2000). Pseudo-Elastic Flexure-Hinges in Robots for Micro

Assembly, Proc. of SPIE, Vol. 4194, pp. 157-167

Hesselbach, J. ; Raatz, A. & Kunzmann, H. (2004a). Performance of Pseudo-Elastic Flexure

Hinges in Parallel Robots for Micro-Assembly Tasks, Annals of CIRP, Vol. 53, No. 1,

pp. 329-332

Hesselbach, J.; Wrege, J.; Raatz, A.; Becker, O. (2004b) Aspects on Design of High Precision

Parallel Robots, Journal of Assembly Automation, Vol. 24, No. 1, pp. 49-57

Hesselbach, J. ; Wrege, J. ; Raatz, A. ; Heuer, K. & Soetebier, S. (2005). Microassembly -

Approaches to Meet the Requirements of Accuracy, In : Advanced Micro &

Nanosystems Volume 4 - Micro-Engineering in Metals and Ceramics Part II, Löhe, D.

(Ed.) & Haußelt, J. (Ed.), pp. 475-498, Wiley-VCH Verlag, ISBN 3-527-31493-8,

Weinheim

Höhn, M. (2001). Sensorgeführte Montage hybrider Mikrosysteme, Forschungsberichte iwb,

Herbert Utz Verlag, ISBN 3-8316-0012-0, München

Howell, L.L. ; Midha, A. (1995). Parametric Deflection Approximations for End-Loaded,

Large-Deflection Beams in Compliant Mechanisms, Journal of Mechanical Design,

Vol. 117, No. 3, pp. 156-165

244

Parallel Manipulators, Towards New Applications

Paros, J.M. ; Weisbord, L. (1965). How to Design Flexure Hinges, Machine Design, Vol. 25,

pp. 151-156

Raatz, A. (2006). Stoffschlüssige Gelenke aus pseudo-elastischen Formgedächtnislegierungen in

Parallelrobotern, Vulkan Verlag, ISBN 3-8027-8691-2, Essen

Raatz, A. & Hesselbach, J. (2007). High-Precision Robots and Micro Assembly, Proceedings of

COMA ’07 International Conference on Competitive Manufacturing, pp. 321-326,

Stellenbosch, South Africa, 2007

Simnofske, M. ; Schöttler, K. ; Hesselbach, J. (2005). Micabof2 – robot for micro assembly,

Production Engineering, Vol. 12, No. 2, pp. 215-218

Smith, S.T. (2000). Flexures - Elements of Elastic Mechanisms. Gordon & Breach Science

Publishers, ISBN 90-5699-261-9, Amsterdam

Tutsch, R.; Berndt, M. (2003). Optischer 3D-Sensor zur räumlichen Positionsbestimmung bei

der Mikromontage, Applied Machine Vision, VDI-Report No. 1800, Stuttgart, pp. 111-

118

Wicht, H. & Bouchaud, J. (2005). NEXUS Market Analysis for MEMS and Microsystems III

2005-2009, mst news, Vol. 5, 2005, pp. 33-34

12

Dynamics of Hexapods with Fixed-Length Legs

Rosario Sinatraa and Fengfeng Xib

aUniversità di Catania, 95125, Catania,

bRyerson University Toronto, Ontario,

aItaly

bCanada

1. Introduction

Hexapod is a new type of machine tool based on the parallel closed-chain kinematic

structure. Compared to the conventional machine tool, parallel mechanism structure offers

superior stiffness, lower mass and higher acceleration, resulting from the parallel structural

arrangement of the motion systems. Moreover, hexapod has the potential to be highly

modular and re-configurable, with other advantages including higher dexterity, simpler and

fewer fixtures, and multi-mode manufacturing capabilities.

Initially, hexapod was developed based on the Stewart platform, i.e. the prismatic type of

parallel mechanism with the variable leg length. Commercial hexapods, such as VARIAX

from Giddings & Lewis, Tornado from Hexel Corp., and Geodetic from Geodetic

Technology Ltd., are all based on this structure. One of the disadvantages for the variable

leg length structure is that the leg stiffness varies as the leg moves in and out. To overcome

this problem, recently the constant leg length hexapod has been envisioned, for instance,

HexaM from Toyada (Susuki et al., 1997). Hexaglibe form the Swiss Federal Institute of

Techonology (Honegger et al., 1997), and Linapod form University of Stuttgart (Pritschow &

Wurst, 1997). Between these two types, the fixed-length leg is stiffer (Tlusty et al., 1999) and,

here, becoming popular.

Dynamic modeling and analysis of the parallel mechanisms is an important part of hexapod

design and control. Much work has been done in this area, resulting in a very rich literature

(Fichter, 1986; Sugimoto, 1987; Do & Yang, 1988; Geng et al., 1992; Tsai, 2000; Hashimoto &

Kimura, 1989; Fijany & Bejezy, 1991). However, the research work conducted so far on the

inverse dynamics has been focused on the parallel mechanisms with extensible legs.

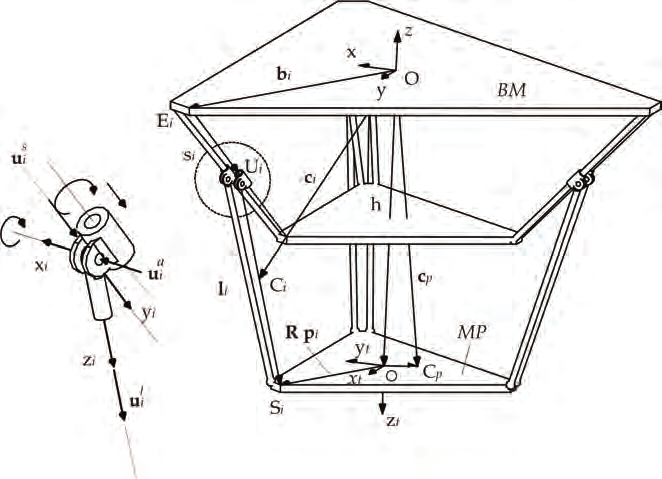

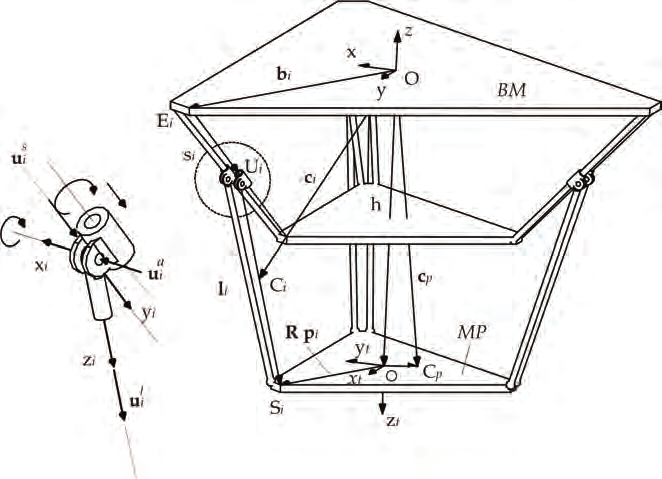

In this chapter, first, in the inverse dynamics of the new type six d.o.f. hexapods with fixed-

length legs, shown in Fig. 1, is developed with consideration of the masses of the moving

platform and the legs. (Xi & Sinatra, 2002) This system consists of a moving platform MP

and six legs sliding along the guideways that are mounted on the support structure. Each

leg is connected at one end to the guideway by a universal joint and at another end to the

moving platform by a spherical joint. The natural orthogonal complement method (Angeles

& Lee, 1988; Angeles & Lee, 1989) is applied, which provides an effective way of solving

multi-body dynamics systems. This method has been applied to studying serial and parallel

manipulators (Angeles & Ma, 1988; Zanganesh et al., 1997) automated vehicles (Saha &

Angeles, 1991) and flexible mechanisms (Xi & Sinatra, 1997). In this development, the

246

Parallel Manipulators, Towards New Applications

Newton-Euler formulation is used to model the dynamics of each individual body,

including the moving platform and the legs. All individual dynamics equations are then

assembled to form the global dynamics equations. Based on the complete kinematics model

developed, an explicit expression is derived for the natural orthogonal complement which

effectively eliminates the constraint forces in the global dynamics equations. This leads to

the inverse dynamics equations of hexapods that can be used to compute required actuator

forces for given motions.

Fig. 1. New hexapod design

Finally, for completeness of the dynamic study of the parallel manipulator with the fixed-

length legs, the static balancing is studied (Xi et al., 2005).

A great deal of work has been carried out and reported in the literature for the static

balancing problem. For example, in the case of serial manipulator, Nathan (Nathan, 1985)

and Hervé (Hervé, 1986) applied the counterweight for gravity compensations. Streit et al.

(Streit & Gilmore, 1991), (Walsh et al., 19) proposed an approach to static balanced rotary

bodies and two degrees of freedom of the revolute links using springs. Streit and Shin

presented a general approach for the static balancing of planar linkages using springs(Streit

& Shin, 1980). Ulrich and Kumar presented a method of passive mechanical gravity

compensation using appropriate pulley profiles (Ulrich & Kumar, 1991). Kazerooni and Kim

presented a method for statically-balanced direct drive arm (Kazerooni & Kim, 1990).

For the parallel manipulator much work was done by Gosselin et al. Research reported in

(Gosselin & Wang, 1998) was focused on the design of gravity-compensated of a six–degree-

of-freedom parallel manipulator with revolute joints. Each leg with two links is connected

by an actuated revolute joint to the base platform and by a spherical joints the moving

platform. Two methods are used, one approach using the counterweight and the other using

springs. In the former method, if the centre of mass of a mechanism can be made stationary,

the static balancing is obtained in any direction of the Cartesian space. In the second

approach, if the total energy is kept constant, the mechanism is statically balanced only in

the direction of gravity vector. The static balancing conditions are derived for the three-

degree-of-freedom spatial parallel manipulator (Wang & Gosselin, 1998) and in similar

Dynamics of Hexapods with Fixed-Length Legs

247

conditions are obtained for spatial four-degree-of-freedom parallel manipulator using two

common methods, namely, counterweights and springs (Wang & Gosselin, 2000).

In this chapter, following the same approach presented by Gosselin, the static balancing of

the six d.o.f. platform type parallel manipulator with the fixed-length legs shown is studied.

The mechanism can be balanced using the counterweight with a smart design of

pantograph. The mechanism can be balanced using the method, i.e., the counterweight with

a smart design of pantograph. By this design a constant global center of mass for any

configurations of the manipulator is obtained.

Finally, the leg masses become important for hexapods operating at high speeds, such as

high-speed machining; then in the future research and development the effect of leg inertia

on hexapod dynamics considering high-speed applications will be investigated.

2. Kinematic modeling

2.1 Notation

As shown in Figure 2, this hexapod system consists of a moving platform MP to which a

tool is attached, and six legs sliding along the guideways that are mounted on the support

structure including the base platform BP. Each leg is connected at one end to the guideway

by a universal joint and at another end to the moving platform by a spherical joint.

Fig. 2. Kinematic notation of the i th leg

The coordinate systems used are a fixed coordinate system O-xyz is attached to the base and

a local coordinate system O t- xtytzt attached to the moving platform. Vector b i, s i, and l i are directed from O to B i, from B i to U i, and from U i to S i respectively. B i indicates the position of one end of the i th guideway attached to the base, U i indicates the position of the i th

248

Parallel Manipulators, Towards New Applications

universal joint, and Si indicates the position of the i th spherical joint. Six legs are numbered

from 1 to 6.

Furthermore, a local coordinate frame O i-x i y i z i is defined for each leg, with its origin located

at the center of the i th universal joint. Two unit vectors are used. Unit vector l

u i is along the

leg length representing the direction of the i th leg, and unit vector s

u i is along the guideway

representing the direction of the i th guideway. The orientation of the i th coordinate frame

with respect to the base can therefore be defined by a 3 × 3 rotation matrix, for i = 1,…,6, as

a

l

a

l

Q = ⎡u

u × u

u ⎤

i

⎣ i

i

i

i ⎦

(1)

where a

u i is expressed as

s

u × l

u

a

u =

i

i

i

(2)

s

u × l

i

u i

Note that vector l

u i is configuration-dependent and determined for the given location of the

moving platform; vector s

u i is constant and defined by the geometry of the hexapod.

For the purpose of carrying out the inverse dynamics analysis of the hexapod, the following

symbols are defined. As shown in Figure 2, C i is the center of mass of the i th leg, C p is the

center of mass of the moving platform, c, c and c are the position, velocity and acceleration

i

i

vectors, respectively, of C i with respect to the fixed coordinate frame, ρ is the vector

pointing from O t to C p with respect to the local coordinate frame O t-x t y t z t.

2.2 Kinematics

Consider one branch of the leg-guideway system, as shown in Figure 2, the following loop

equation for i = 1,…,6, holds,

h + Rp − b − s − l =

i

i

i

i

0

(3)

where h and R are the vector and rotation matrix that define the position and orientation of

the moving platform relative to the base, respectively, p i is the vector representing the

position of the ith spherical joint on the moving platform in the local coordinates.

Since the leg always moves along the guideway, s i can be expressed as

s =

s

i

i

s u i

(4)

where is is a scalar representing the displacement of the i th actuator along the guideway.

Likewise, leg vector l i can be expressed as

l =

l

i

i

l u i

(5)

where li is a scalar representing the fixed length of the i th leg. As mentioned in Section 2.1,

the leg axis is parallel to the z i axis of the local coordinate frame O i-x i y i z i. In the light of eq.(1), l

u i can be expressed as

Dynamics of Hexapods with Fixed-Length Legs

249

l

u =

i

Q iz i (6)

Substituting eqs.(4 & 5) into eq.(3) and rearranging it yields the following kinematics

equations for the fixed-length leg hexapod, for i = 1,…,6,

s

s u = h + Rp − b −

l

i i

i

i

i

l u i

(7)

To obtain the velocity of the moving platform, taking the time derivative of eq. (7) yields

s

s u = v +

i i

(ω × Rp i ) − (ω ×

i

l i )

(8)

where v and ω are the vectors representing the velocity and angular velocity of the moving

platform, respectively, and ω is the vector representing the angular velocity of the i th leg.

i

Furthermore, by taking dot product on both sides of eq.(8) by l i, it leads to

s

s u ⋅ l =

i i