Hybrid Parallel Robot for the

Assembling of ITER

Huapeng Wu, Heikki Handroos and Pekka Pessi

Lappeenranta University of Technology

Finland

1. Introduction

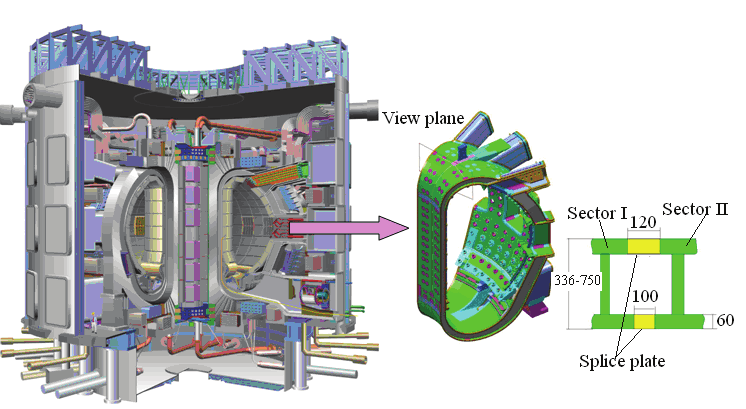

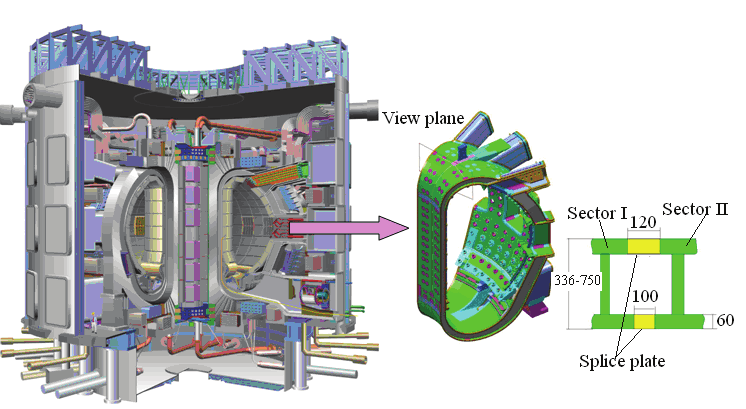

The international thermonuclear experimental reactor (ITER) is a joint international research

and development project that aims to demonstrate the scientific and technical feasibility of

fusion power. The reactor tokomak (vacuum vessel) is made of stainless steel, and contains

nine sectors welded together; each sector has about the size of 10 meter high and 6 meter

wide. The sectors of ITER vacuum vessel (VV) (Fig. 1) require more stringent tolerance

(±5mm) than normally expected for the size of the structure involved. The walls (inner wall

and outer wall) of ITER sectors are of 60mm thick and are joined by high quality leak tight

welds. In addition to the initial vacuum vessel assembly, the sectors may have to be

replaced for repair. Meanwhile, the machining operations and lifting of a possible e-beam

gun column system require extreme stiffness property and good accuracy for a machine

tool. The payload to weight ratio also has to be significantly better than it is in the

commercial industrial robots.

The conventional robots, providing a high nominal payload, are lack of stiffness and

accuracy in such machining condition. Since commercially available machines capable of

handling large payloads require floor mounting and their workspaces are insufficient for

reaching the cross section at a single mounting position, a special robot is needed. Parallel

robots have high stiffness, high dynamic performance and good payload to weight ratio in

comparison with the conventional serial robots. Stewart [1] presented the novel idea of six-

degree-of-freedom parallel robot in 1960’s. A remarkable number of research articles and

books about parallel manipulators have been published during the last two decades. There

are also a number of successful industrial applications developed [2], [3], [4], [7]. The

parallel manipulators have many potential advantages compared with the conventional

serial link manipulators. Parallel manipulators are closed-loop mechanism presenting good

performances in terms of accuracy, rigidity, high speed, and ability to handle large loads.

They are becoming popular in applications such as machining, welding, assembly, flight

and vehicle simulators, mining machines, and pointing devices [2], [3], [4], [7]. The most

important drawback of parallel robots is the small workspace, which can be made larger by

adding additional serial axes in the robot.

For the assembly of the ITER vacuum vessel sector, the precise positioning of welding end-

effectors at some distance in a confined space from the available supports will be required,

364

Parallel Manipulators, Towards New Applications

while it is not possible using conventional machines or robots. The parallel robot presented

in this paper is able to carry out welding and machining processes from inside the ITER

vacuum vessel, consisting of a six degree-of-freedom parallel mechanism mounted on a

carriage driven by electric motor/gearbox on a rack. The robot carries both welding gun

(such as a TIG, hybrid laser or e-beam welding gun to weld the inner and outer walls of the

ITER vacuum vessel sectors) and machining tools (to cut and mill the walls with necessary

accuracy). It can also carry other heavy tools and parts to a required position inside the

vacuum vessel.

The robot offers not only a device but also a methodology for assembling and repairing VV.

For assembling, an on-line six-degree-of-freedom-seam-finding algorithm has been

developed. The algorithm enables the robot to find welding seam automatically in a very

complex environment. For machining, the multi flexible machining processes carried out

automatically by the robot have also been investigated, including edge cutting, smoothing,

and defect point milling. The kinematic design of the robot has been optimised for the ITER

access and a hydraulically actuated prototype has been built. Finally the experimental

results are presented and discussed. The earlier development phases of the robot are

presented in [8] and [9].

2. Structure of VV and assembling process

The inner and outer walls of the VV of ITER are made of 60mm-thick stainless steel 316L

and are welded together through an intermediate, so-called “splice plate”, inserted between

the sectors to be joined. The splice plates have two important functions: ( i) to allow access to

bolt together the thermal shield between the VV and coils; and ( ii) to compensate the

mismatch between adjacent sectors to give a good fit-up of the sector-sector butt weld. The

robot’s end-effector will have to pass through the inner wall splice plates opening to reach

the outer wall. As shown in Fig.1, the assembly and repairing processes have to be carried

out from inside the vacuum vessel.

Fig.1 ITER and VV sectors to be welded

Hybrid Parallel Robot for the Assembling of ITER

365

The assembly or repair will be performed according to four phases: cutting, edge machining

and smoothing, welding, and non-destructive tests (NDT) control. The robot will carry out

welding, machining, and inspecting inside the VV. The maximum robot force arises from

cutting. It can be up to 3kN.

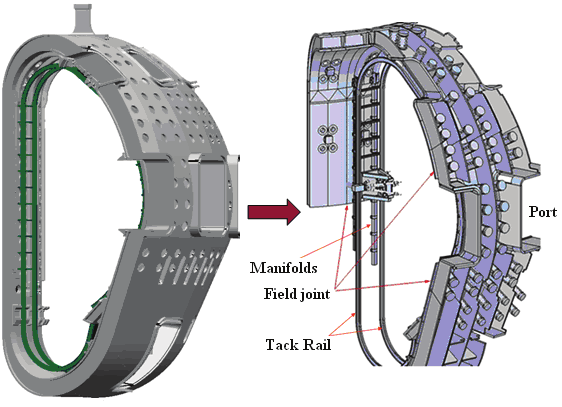

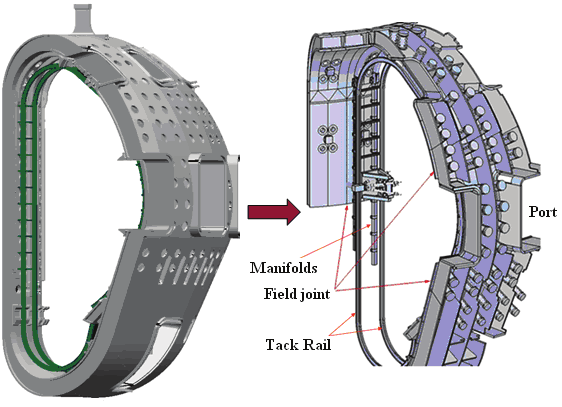

Fig.2 The track rail mounted inside VV and robot on the track

In order that the robot can operate in the cross section of the vessel, a track is assembled

inside the sector. The track has a rack on one side of the rail and it is supported by manifolds

and beams (shown in Fig. 2). The robot driven on the rail carries out welding or machining

along the edge of the sector. After finishing the assembly of two sectors, the robot has to be

moved to the next sector where there is also a track assembled. After finishing the assembly

of all the sectors, the robot can be taken out via the port of VV.

3. Kinematics of parallel robot

3.1 Structure of parallel robot

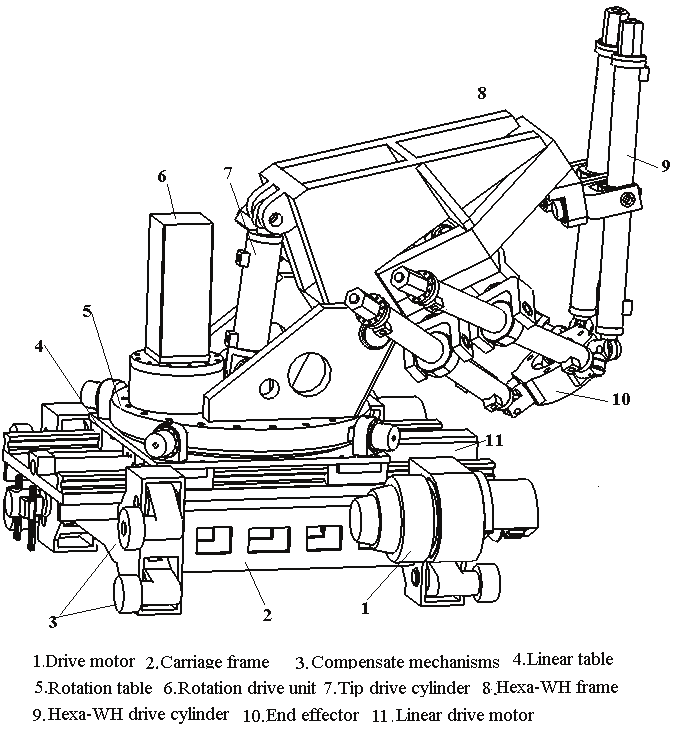

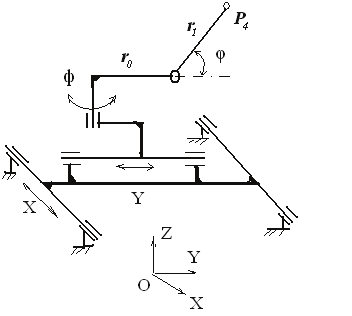

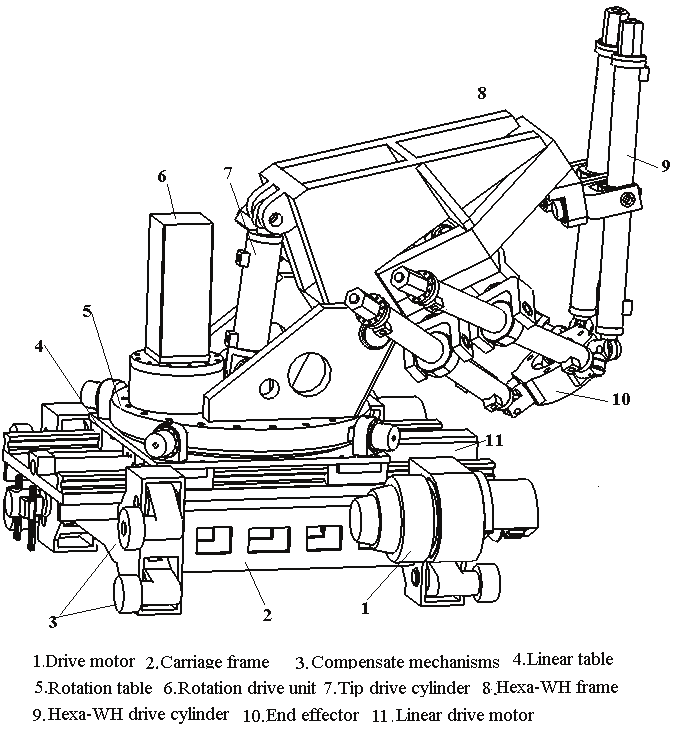

The proposed parallel robot has ten degrees of freedom (Fig. 3). It consists of two relatively

independent sub-structures: ( i) carriage, which provides four additional degrees of freedom,

i.e., rotation, linear motion, tilt rotation and tracking motion, and these four degrees are

added to enlarge the workspace and to offer high mobility; and ( ii) the Hexa-WH parallel

mechanism driven by six hydraulic cylinders contributes six degrees of freedom for the end-

effector. Thus the robot is a hybrid redundant manipulator with four extra degrees of

freedom provided by serial kinematic links.

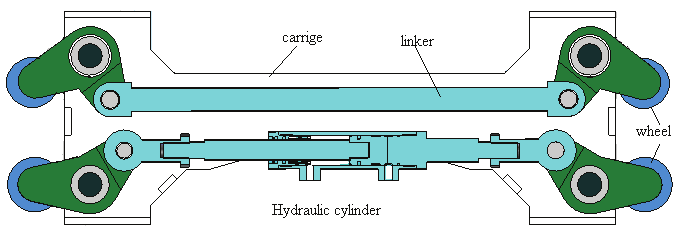

a). Carriage mechanism

The carriage mainly consists of 5 units. i) Carriage frame: The carriage frame is a complex

structure welded by multi-steel-plates, and it is able to carry high payload and offers

enough room to maintain mechanisms. Stiffness and weight are the most important

considerations in the design, and they have been optimized to achieve necessary stiffness

366

Parallel Manipulators, Towards New Applications

with light weight. ii) Tracking drive unit: The tracking drive unit consists of electric motor,

reduction unit CYCLO, V-shape bearing, and driving gear. The electric servo motor with

Fig. 3 Parallel robot

position feedback controller offers the high accurate motion. In order to output large torque

to drive the heavy mass and payload, the reduction unit CYCLO is added to the motor

to reduce speed and to transmit high torque to the driving gear. Two V-shaped wheels keep

the carriage on the tracking rail at right position to avoid the cross motion. Two drive units

are used in the carriage to offer enough torque in order to drive the robot and payload

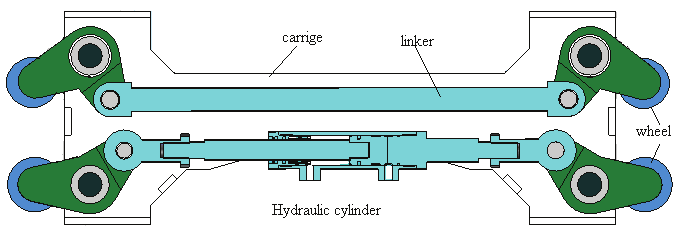

around inside the VV. iii) Compensation mechanism: The compensation system is an important

unit that limits the backlash caused by the inaccurate assembling of the tracking rail and

compensates the distance changing between the wheels in bending area. As the shape of the

VV is very complicated, it is difficult to keep the tracking rails lying on the VV surface in the

accurate position. The position tolerance can be up to ±2mm. The distance of the coupled

wheels has to be adjusted to follow the changes of the rail, and all the wheels must touch the

parallel rails with certain force during motion; hence an adaptive distance compensation

system is needed and it should be able to undertake the summed weight of the robot and

the payload, when the robot is upside down at the top position insider VV. Since the total

Hybrid Parallel Robot for the Assembling of ITER

367

payload is very heavy, a hydraulic cylinder is applied to justify the compensation force

according to the position where the robot is located. Fig. 4 shows the compensation system,

where the upside is the tolerance adaptive mechanism that passively follows the changes of

track rail and the downside is the hydraulic distance compensation system that ensures a

constant force is applied to the rails. iv) Linear drive unit: The linear drive unit enlarges the

workspace of the robot, and consists of five parts: ball screw drive unit, servo motor, rails,

linear bearings, and a table. Two parallel rails are fixed on the carriage frame to offer the

motion crossing the frame and to extend the distance of the robot in direction Y. In direction

Y, the distance from the inner board to the outer board can be 900mm in one VV sector, i.e.,

the robot needs longer reach in this direction, and the linear drive unit helps the robot end-

effector to reach the farther border of the VV. v) Rotation drive unit: This unit offers a rotation

motion about the Z axis, so that the robot can machine the flexible houses on the inner wall

at any position. The rotation drive unit consists of slewing bearing, drive gear, reduction

unit CYCLO, and servo motor. The slewing bearing integrates bearing and gear together,

leading to a compact structure with light weight. The rotation of the unit can reach ±180°.

Fig. 4 Compensation mechanism

b). Hexa-WH

A Stewart based mechanism, driven by six servo control water hydraulic cylinders, offers

six-degree freedom to the end-effector, where the machining head and welding gun are

mounted. Because of the special shape of the VV, a full six-degree freedom motion for tool is

needed to enable the robot to carry out welding and machining. The Hexa-WH can offer the

required accuracy and the high force capacity due to its novel configuration and the

hydraulic drive.

3.2 Kinematics model

The kinematics model is very important for the robot motion control. As the robot has

redundant degree freedom, it is difficult to find the kinematics solution directly. The

kinematics models can first be set up for the carriage and the Hexa-WH separately, and then

be combined together by using an optimization algorithm in solving the redundant problem

[4], [5].

a). Forward kinematics

As described above, the carriage offers the robot the four-degree freedom: two linear

motions and two rotations; while the Hexa-WH offers the end-effector the full six-degree

freedom. The transformation matrix of the robot can be defined as:

368

Parallel Manipulators, Towards New Applications

Tc =T1 ·T2 · T3 ·T4 ·T5 ,

(2)

where

⎡1 0 0 X 1⎤

⎢

⎥

0 1 0 Y ,

T = ⎢

1 ⎥

1

⎢0 0 1 Z ⎥

⎢

1 ⎥

⎣0 0 0

1 ⎦

⎡1 0 0 X 2 ⎤

⎢

⎥

0 1 0 Y

,

T = ⎢

2 ⎥

2

⎢0 0 1 Z ⎥

⎢

2 ⎥

⎣0 0 0

1 ⎦

⎡ cφ − sφ 0 X 3⎤

⎢

⎥ ,

sφ

cφ

0 Y

T = ⎢

3 ⎥

3

⎢ 0

0

1 Z ⎥

⎢

3 ⎥

⎣ 0

0

0

1 ⎦

⎡1 0

0

X 4 ⎤

⎢

⎥ ,

⎢0 cϕ − sϕ Y

T =

4 ⎥

4

⎢0 sϕ

cϕ

Z ⎥

⎢

4 ⎥

⎣0 0

0

1 ⎦

⎡ cα cβ cα sβ sγ − sα cγ cα sβ cγ + sα sγ X 5 ⎤

⎢

⎥ .

⎢ sα cβ sα sβ sγ + cα cγ sα sβ cγ − cα sγ

Y 5 ⎥

T =

5

⎢ − sβ

cβ sγ

cβ cγ

Z ⎥

⎢

5 ⎥

⎣ 0

0

0

1 ⎦

Once the parameters of joints are given, the forward kinematics of the robot can be defined

as

G

G

G

P = T • P = T ⋅ T ⋅ T ⋅ T ⋅ T ⋅ P .

(2)

0

1

2

3

4

5

0

To solve the forward kinematic model of the Hexa-WH, the numeric iterative method can be

employed and it can be solved from its inverse kenamatic model given later in the chapter.

b). Inverse kinematic model of robot

As the robot has four-degree freedom of redundancy, we give an inverse kinematic model

first to the carriage, then to the Hexa-WH.

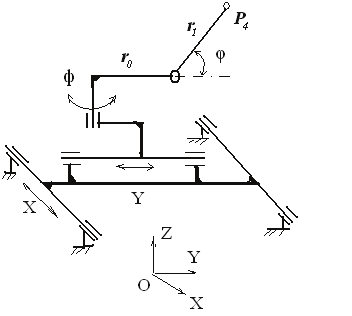

Inverse kinematic model of carriage: The inverse kinematic model of the carriage is defined to

find the values of the four actuators with respect to the frame o for a given position and an

orientation of P 4 on the Hexa-frame. The principle of the carriage mechanism is shown in

Fig. 5. In the application, rotation angle φ is fixed only at a few values, 0°, ±90°, and 180°,

and we can calculate the values of other actuators by fixing φ , i.e., for a given position P4( x,

y, z), the centre of the Hexa-Frame, we have

Hybrid Parallel Robot for the Assembling of ITER

369

X + ( r + r cosϕ) cosφ = x

0

1

,

(3)

Y + ( r + r cosϕ)sinφ = y ,

(4)

0

1

r sin ϕ = Z

1

.

(5)

Then

ϕ = arcsin( Z / r ) ,

(6)

1

X = x − ( r + r cosϕ)cosφ

0

1

,

(7)

Y = y − ( r + r cosϕ) sinφ

0

1

.

(8)

Fig. 5 a) Mechanism of carriage, b) Hexa-WH

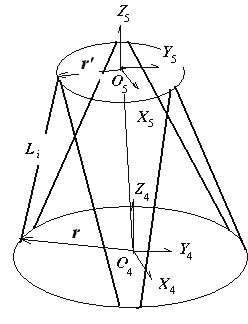

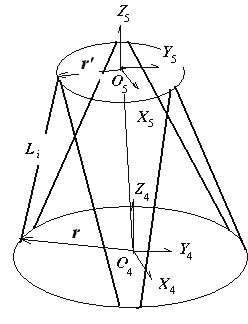

Inverse kinematic model of Hexa-WH: The inverse kinematic model for the Hexa-WH is defined

to find the values for each cylinder at a given position and an orientation of the end-effector

with respect to the Hexa-frame. Here O 4 is coincided with P 4 on the carriage side. Fig.5 b)

demonstrates the coordinates of the Hexa-WH.

The inverse kinematics model for the Hexa-WH is

G

G

=

+ ⋅ ' − ( i = 1, 2, …,6),

(9)

i

L

O O

R

4 5

i

r

i

r

where

⎡ α

c β

c

α

c β

s γ

s − α

s γ

c

α

c β

s γ

c + α

s γ

s ⎤

⎢

⎥

R =

,

⎢ α

s β

c

α

s β

s γ

s + α

c γ

c

α

s β

s γ

c − α

c γ

s ⎥

⎢ − β

s

β

c γ

s

β

c γ

c

⎥

⎣

⎦

370

Parallel Manipulators, Towards New Applications

G ri denotes the vector of the joint of the i th cylinder on the Hexa-frame with respect to frame

o4 and '

ri is the vector of the joint of the i th cylinder on the end-effector with respect to

frame o5.

The length of each cylinder can be found, when ( x, y, z, γ, β, α) is defined with respect to frame o4.

'

G

'

G

l =

= ( O O + R ⋅ − ) • ( O O + R ⋅ − ) .

(10)

i

L

i

4 5

i

r

i

r

4 5

i

r

i

r

There are two ways to combine the two inverse kinematic models to get the solution of the

whole robot. One simple way is to calculate the coordinates (x, y, z, γ , β , α ) of the end-

effector with respect to {O4} and the values for each actuator from equations (3-10) for the

given coordinates of the end-effector with respect to frame {o}, while fixing {O4} at a certain

position with respect to frame {o} according to experience. The another way is to use an

optimization algorithm to find redundant solution, which is subjected to minimize the

deflection of the robot during motion, i.e., min f ( q, l ) , where f is the deflection model of the

l

robot, q is the position vector of the end-effector, and l is the value vector of ten actuators.

For a given q we can find l by solving the optimization problem min f ( q, l ) .

l

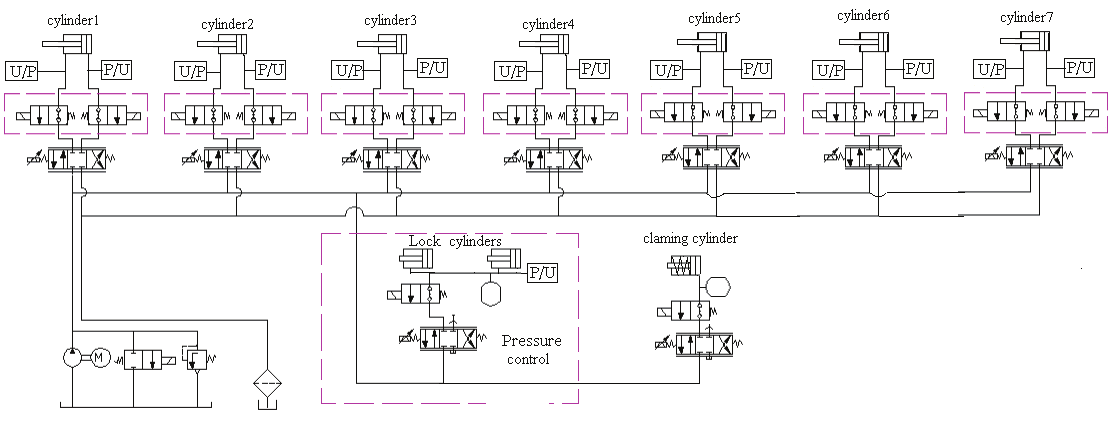

4. Control system

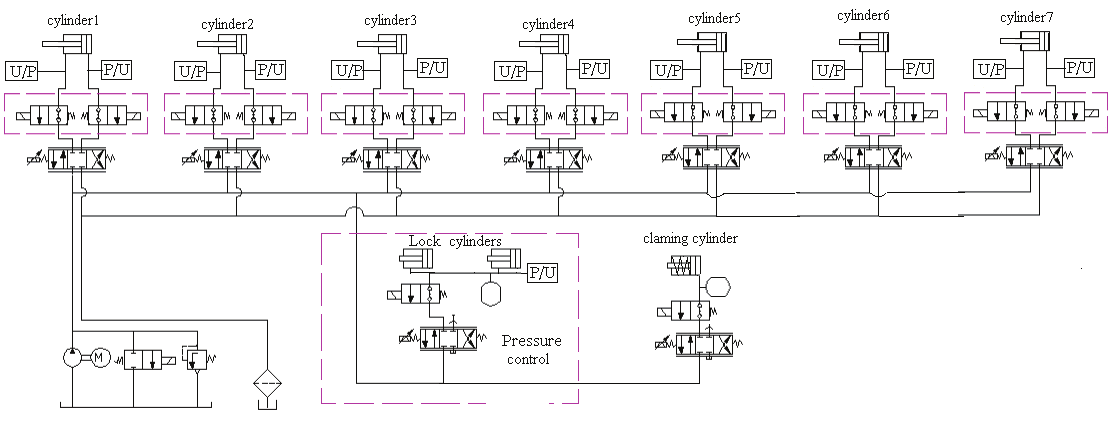

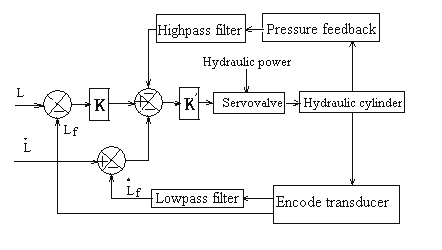

4.1 Hydraulic control system

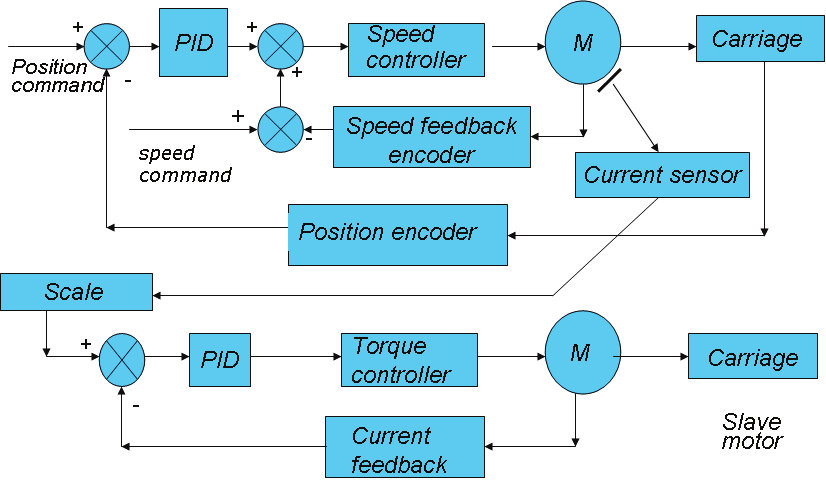

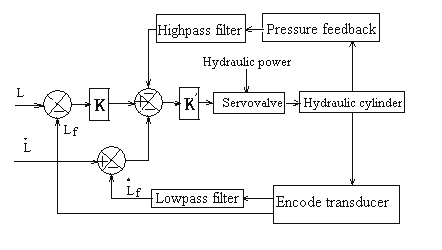

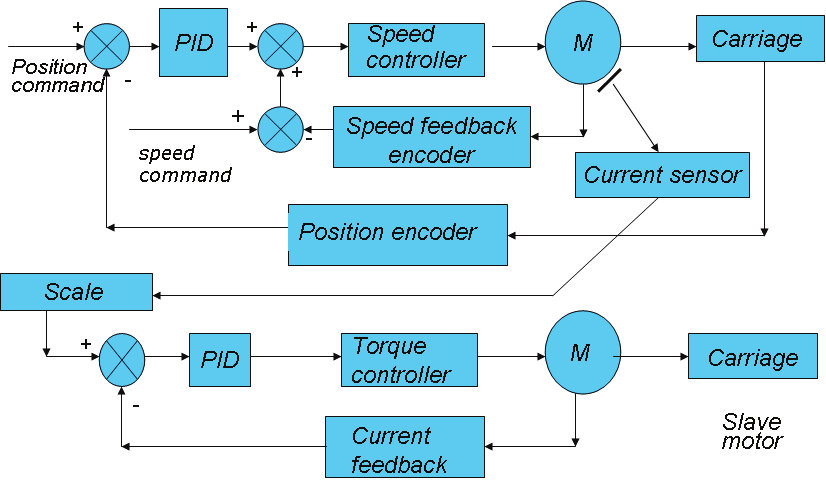

Fig.6 shows the water hydraulic system. Pressure servo control is applied in locking

cylinders. Position servo controller is used in cylinders 1-7. There are three loops in the

servo position control: the position loop together with the speed loop that provide an

accurate and fast trajectory tracking; and the load pressure feedback loop that is applied to

damping the self-excited oscillations, which normally occur in the natural frequency. The

speed loop can eliminate the speed error, while the pressure feedback damps the vibration

of hydraulic actuators (Fig. 7).

Fig.6 Water hydraulic circle

Hybrid Parallel Robot for the Assembling of ITER

371

The hydraulic cylinders normally lack damping that makes the cylinder contro