Angeles, J. (2005). The degree of freedom of parallel robots: a group-theoretic approach,

Proceedings of IEEE International Conference on Robotics and Automation, pp. 1017-

1024, Barcelona, Spain, April 2005

Basu, D. & Ghosal, A. (1997). Singularity analysis of platform-type multi-loop spatial

mechanisms. Mechanism and Machine Theory, Vol. 32, No. 3, pp. 375-389

Benov, I. (2001). Delta parallel robot – the story of success. May, 6,

http://www.parallemic.org/Reviews/Review002.html

Bonev, L. & Zlatanov, D. (2001). The mystery of the singular SUN translational parallel

robot. June, 12, 2001, http://www.parallemic.org/Reviews/Review004.html

Bonev, I.A. et al. (2001). A closed-form solution to the direct kinematics of nearly general

parallel manipulators with optimally located three linear extra sensors. IEEE

Transaction on Robotics and Automation, Vol. 17, No. 2, pp. 148-156

Bottema, O. & Roth, B. (1990). Theoretical kinematics. New York: Dover Publications

Brogardh, T. PKM research – important issues, as seen from a product development

perspective at ABB robotics, Workshop on Fundamental Issues and Future Research

Directions for parallel Mechanisms and Manipulators, Quebec, Canada, 2002

444

Parallel Manipulators, Towards New Applications

Bruyninckx, H. (1997). The 321-hexa: a fully parallel manipulator with closed-form position

and velocity kinematics, Proceedings of IEEE Conference on Robotics and Automation,

pp. 2657-2662, Albuquerque, April, 1997

Carretero, J.A.; Podhorodeski, R.P.; Nahon, M.A. & Gosselin, C.M. (2000). Kinematic

analysis and optimization of a new three degree-of-freedom spatial parallel

manipulator. ASME Journal of Mechanical Design, Vol. 122, pp. 17-24

Chablet D, D.; Wenger, P. Design of a three-axis isotropic parallel manipulator for

machining applications: the orthoglide, Workshop on Fundamental Issues and Future

Research Directions for Parallel Mechanisms and Manipulators, Quebec, Canada, Oct.,

2002

Cheung, J.W.F.; Hung, Y.S. & Widdowson, G.P. (2002). Design and analysis of a novel 4-dof

parallel manipulator for semiconductor applications, Proceedings of the 8th

Mechatronics Forum International Conference, pp. 1358-1366, Twente, Netherlands:

Drebbel Institute for Mechatronics

Chiu, Y.J. & Perng, M-H. (2001). Forward kinematics of a general fully parallel manipulator

with auxiliary sensors. International Journal of Robotics Research, Vol. 20, No. 5, pp.

401-414

Choi, H.-B.; Konno, A. & Uchiyama, M. (2003). Closed-form solutions for the forward

kinematics of a 4-DOFs parallel robot H4, Proceedings of IEEE/RSJ International

Conference on Intelligent Robots and Systems, pp. 3312-3317, Las Vegas, USA, October,

2003

Clavel, R. (1988). DELTA, a fast robot with parallel geometry, Proceedings of the 18th

International Symposium on Industrial Robot, pp. 91-100, April, 1988, Lausanne

Collins, C.L. & Long, G.L. (1995). The singularity analysis of an in-parallel hand controller

for force-reflected teleoperation. IEEE Transactions on Robotics and Automation, Vol.

11, No. 5, pp. 661-669

Company, O. & Pierrot, F. (1999). A new 3T-1R parallel robot, Proceedings of the 9th

International Conference on Advanced Robotics, pp. 557-562, October, 1999, Tokyo,

Japan

Company, O.; Marquet, F. & Pierrot F. (2003). A new high-speed 4-DOF parallel robot

synthesis and modeling issues. IEEE Transactions on Robotics and Automation, Vol.

19, No. 3, pp. 411-420

Company, O.; Pierrot, F. & Fouroux, J.C. (2005). A method for modeling analytical stiffness

of a lower mability parallel manipulator, Proceedings of IEEE International Conference

on Robotics and Automation, pp. 18-22, Barcelona, Spain, April, 2005, Milan,

September, 1995

Di Gregorio, R. & Parenti-Castelli, V. (1999). Mobility analysis of the 3-UPU parallel

mechanism assembled for a pure translational motion, Proceedings of the

IEEE/ASME International Conference on Advanced Intelligent Mechatronics, pp. 520-

525, Atlanta, GA, September, 1999

Fattah, A. & Kasaei, G. (2000). Kinematics and dynamics of a parallel manipulator with a

new architecture. Robotica, Vol. 18, pp. 535-543

A Novel 4-DOF Parallel Manipulator H4

445

Faugère, J.C. & Lazard, D. (1995). The combinatorial classes of parallel manipulators.

Mechanism and Machine Theory, Vol. 30, No. 6, pp. 765-776

Feng-Cheng, Y. & Haug, E.J. (1994). Numerical analysis of the kinematic working capability

of mechanism. ASME Journal of Mechanical Design, Vol. 116, pp. 111-117

Funabashi, H. & Takeda, Y. (1995). Determination of singular points and their vicinity in

parallel manipulators based on the transmission index, Proceedings of the Ninth

World Congress on the Theory of Machine and Mechanism, pp. 1977-1981,

Gosselin, C.M. & Angeles, J. (1989). The optimum kinematic design of a spherical three-

degree-of-freedom parallel manipulator. ASME Journal of Mechanisms, Transmission

and Automation in Design, Vol.111, No.2, pp. 202-207

Gosselin, C. & Angeles, J. (1990). Singularity analysis of closed-loop kinematic chains. IEEE

Transaction on Robotics and Automation, Vol. 6, No. 3, pp. 281-290

Gosselin, C. (1990). Dexterity indices for planar and spatial robotic manipulators. Proceedings

of the IEEE International Conference on Robotics and Automation, pp. 650-655,

Cincinnati, May, 1990

Gosselin, C. (1996). Parallel computational algorithms for the kinematics and dynamics of

planar and spatial parallel manipulators. A SME Journal of Dynamic Systems,

Measurement and Control, Vol. 118, No. 1, pp. 22-28

Gosselin, C.M. & St-Pierre, É. (1997). Development and experimentation of a fast 3-DOF

camera-orienting device. The International Journal of Robotics Research, Vol.16, No.5,

pp. 619-629

Gough, V.E. (1956). Contribution to discussion of papers on research in automobile stability,

control and tyre performance, Proceedings of the Automotive Division of the Institution

of Mechanical Engineers, Part D, pp. 392-394

Gregorio, R. D. (2001). A new parallel wrist using only revolute pairs: the 3-RUU wrist.

Robotica, Vol. 19, pp. 305-309

Hao, F. McCarthy, J.M. (1998). Conditions for line-based singularities in spatial platform

manipulators. Journal of Robotic Systems, Vol. 15, No. 1, pp. 43-55

Hesselbach, J. & Kerle, H. (1995). Structurally adapted kinematic algorithms for parallel

robots up to six degrees if freedom (dof), Proceedings of the 9th World Congress on the

Theory of Machines and Mechanisms, pp. 1935-1939, Milan, Italy, August, 1995

Hunt, K.H. (1978). Kinematic geometry of mechanism. Department of Mechanical

Engineering, Monash University, Clayton, Victoria, Australia

Husty, M.L. (1996). On the workspace of planar three-legged platforms. Proceedings of the

World Automation Congress, Vol. 3, pp. 339-344, Montpellier, May, 1996

Jo, D.Y. & Haug, E.J. (1989). Workspace analysis of closed loop mechanism with unilateral

constraints. Proceedings of the ASME Design Automation Conference, pp. 53-60,

Montreal, September, 1989

Joshi, S.A. & Tsai L.-W. (2002) Jacobian analysis of limited-dof parallel manipulators. ASME

Journal of Mechanical Design, Vol. 124, No. 2, pp. 254-258

446

Parallel Manipulators, Towards New Applications

Kim, D.; Chung, W. & Youm, Y. (2000). Analytic jacobian of in-parallel manipulators.

Proceedings of IEEE International Conference on Robotics and Automation, pp. 2376-

2381, San Francisco, April, 2000

Kim, S.-G. & Ryu, J. (2003). New dimensionally homogeneous jacobian matrix formulation

by three end-effector points for optimal design of parallel manipulators. IEEE

Transactions on Robotics and Automation, Vol. 19, No. 4, pp. 731-736

Krut, S.; Company, O. &Benoit, M. et al. (2003). I4: a new parallel mechanism for scara

motions, Proceedings of IEEE International Conference on Robotics and Automation, pp.

1875-1880, Taipei, Taiwan, September, 2003

Krut, S.; Nabat, V.; Company, O. & Pierrot, F. (2004). A high-speed parallel robot for scara

motions, Proceedings of IEEE International Conference on Robotics and Automation, pp.

4109-4115, New Orleans, USA, April, 2004

Li, Q. & Huang, Z. (2003). Mobility analysis of lower-mobility parallel manipulators based

on screw theory, Proceeding of IEEE International Conference on Robotics and

Automation, pp. 1179-1184, Taipei, Taiwan, September, 2003

Liu, G.F.; Lou, Y.J. & Li, Z.X. (2003). Singularities of parallel manipulators: a geometric

treatment. IEEE Transactions on Robotics and Automation, Vol. 19, No. 4, pp. 579-594

Merlet, J.P. (1992). On the infinitesimal motion of a parallel manipulator in singular

configurations, Proceedings of IEEE International Conference on Robotics and

Automation, pp. 320-325, Nice, France, May, 1992

Merlet, J.-P. (2000). Kinematics’ not dead, Proceedings of IEEE International Conference on

Robotics & Automation, pp. 1-6, San Francisco, CA, April, 2000

Merlet, J.-P. & Daney, D. (2005). Dimensional synthesis of parallel robots with a guaranteed

given accuracy over a specific workspace, Proceedings of IEEE International

Conference on Robotics and Automation, pp. 19-22, Barcelona, Spain, April, 2005

Merlet, J.-P. (2006). Parallel Robots (Second Edition), Springer, Dordrecht, The Netherlands

Nabat, V.; Company, O. & Krut, M. et al. (2005). Part 4: very high speed parallel robot for

pick-and-place, Proceedings of IEEE International Conference on Intelligent Robots and

Systems, pp. 553-558, Edmonton, Canada, August, 2005

Nabat, V.; Company, O. & Pierrot, F. (2006). Dynamic modeling and identification of Part 4,

a very high speed parallel manipulator, Proceedings of the International Conference on

Intelligent Robots and Systems, pp. 496-501, Beijing, China, October, 2006

Parenti-Castelli, P. & Di Gregorio, P. (20010). Real-time actual pose determination of the

general fully parallel spherical wrist, using only one extra sensor. Journal of Robotic

Systems, Vol. 18, No. 12, pp. 723-729

Pennock, G.R. & Kassner, D.J. (1990). Kinematic analysis of a planar eight-bar linkage:

application to a platform-type robot, ASME Proceedings of the 21th Biennial

Mechanism Conference, pp. 37-43, Chicago, September, 1990

Pierrot, F. & Company, O. (1999). H4: a new family of 4-dof parallel robots, Proceedings of the

1999 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, pp.

508-513, Atlanta, USA, September, 1999

A Novel 4-DOF Parallel Manipulator H4

447

Pottmann, H.; Peternell, M. & Ravani, B. (1999). An introduction to line geometry with

applications. Compter Aided Design, Vol. 31, pp. 3-16

Reboulet, C. & Robert, A. (1985). Hybrid control of a manipulator with an active compliant

wrist, The 3rd International Symposium of Robotics Research, pp. 76-80, Gouvieux,

France, October, 1985

Renaud, P.; Andreff, N. & Marquet, F. et al.. (2003). Vision-based kinematic calibration of a

H4 parallel mechanism. Proceedings of the IEEE International Conference on Robotics &

Automation, pp. 1191-1196, Taipei, Taiwan, September, 2003

Robotics Department of LIRMM. H4 with rotary drives: a member of H4 family, dedicated

to high speed applications.

http://www.lirmm.fr/w3rob/SiteWeb/detail_resultat.php?num_resultat=7&num

_topic=1& num_projet=1&num_activite=3

Rolland, L. The manta and the kanuk: novel 4-dof parallel mechanisms for industrial

handling. ASME Dynamic Systems and Control Division, IMECE’99 Conference, pp.

831-844, Nashville, USA, November 1999

Romdhane, L.; Affi, Z. & Fayet, M. (2002). Design and singularity analysis of a 3-

translational-DOF in-parallel manipulator. ASME Journal of Mechanical Design, Vol.

124, pp. 419-426

Ryu, J. & Cha, J. (2003). Volumetric error analysis and architecture optimization for accuracy

of HexaSlide type parallel manipulators. Mechanism and Machine Theory, Vol. 38, pp.

227-240

Steward, D. (1965). A platform with 6 degrees of f reedom. Proceedings of the Institution of

Mechanical Engineers, Vol. 180, Part 1, No. 15, pp. 371-386, British

St-Onge, B.M. & Gosselin, C.M. (2000). Singularity analysis and representation of the general

Gaugh-Steward platform. International Journal of Robot Research, Vol.19, No. 3, pp.

271-288

Su, Y.X.; Duan, B.Y. & Peng, B. et al.. (2003). Singularity analysis of fine-tuning stewart

platform for large radio telescope using genetic algorthm. Mechatronics, Vol. 13, pp.

413-425

Tsai, L.-W. (1996). Kinematics of a three-DOF platform with three extensible limbs. Recent

Advances in Robot Kinematics, Kluwer Academic Publishers, pp. 401-410

Tsai, L.-W. & Joshi, S.A. (2000). Kinematics and optimization of a spatial 3-UPU parallel

manipulators. A SME Journal of Mechanical Design, Vol. 122, No.4, pp. 439-446

Wolf, A. & Shoham, M. (2003). Investigation of parallel manipulators using linear complex

approximation. ASME Journal of Mechanical Design, Vol. 125, No. 3, pp. 564-572

Wu, J.; Yin, Z. & Xiong, Y. (2006). Singularity analysis of a novel 4-dof parallel manipulator

H4. International Journal of Advanced Manufacturing and Technology, Vol. 29, pp. 794-

802

Zlatanov, D.; Fenton, R.G. & Benhabit, B. (1994). Singularity analysis of mechanism and

robots via a motion-space model of the instantaneous kinematics. Proceedings of

IEEE International Conference on Robotics and Automation, pp. 980-991, San

Diego, CA, May, 1994

448

Parallel Manipulators, Towards New Applications

Zlatanov, D.; Benov, I.A. & Gosselin, C.M. (2002). Constraint singularities of parallel

mechanisms, Proceedings of the IEEE International Conference on Robotics and

Automation, pp. 496-502, Washington DC, May, 2002

Zobel, P.B., Di Stefano, P. & Raparelli, T. (1996). The design of a 3 dof parallel robot with

pneumatic dirves, Proceedings of the 27th International Symposium on Industrial Robot,

pp. 707-710, October, 1996, Milan

20

Human Hand as a Parallel Manipulator

Vladimir M. Zatsiorsky ad Mark L. Latash

Department of Kinesiology, The Pennsylvania State University

1. Introduction

When a human hand grasps an object the hand can be viewed as a parallel manipulator. In

general, the mathematical analyses of the human hands and multi-fingered robot hands

(Murray et al. 1994) are similar. In particular, concepts developed in robotics such as contact

models, e.g. soft-finger model, grasp matrix, form and force closure grasps, internal forces,

etc. can be applied to analyze the performance of the human hands. Multi-finger prehension

is an example of a mechanically redundant task: the same resultant forces on the object can

be exerted by different digit forces. People however do not use all the mechanically

available options; when different people perform a certain manipulation task they use a

limited subset of solutions.

Studies on human prehension deal with four main issues:

1. Description of the behavior: What are the regularities in force patterns applied at the

fingertip-object interfaces when people manipulate objects?

2. Are the observed patterns dictated by the task and hand mechanics? The mechanical

properties of the hand and fingers are complex, and it is not always evident whether the

findings are direct consequences of the mechanical properties of the hand or they are

produced by a neural control process.

3. If the observed facts/phenomena are not of mechanical origin are they mechanically

necessitated? In other words, can the task be performed successfully in another way?

4. If reproducible phenomena are not mechanical and not mechanically-necessitated, the

question arises why the central nervous system (CNS) facilitates these particular

phenomena. This is a central question of the problem of motor redundancy in general:

Why does the CNS prefer a certain solution over other existing solutions?

The present chapter briefly reviews some specific features of the human hand and the

involved control mechanisms. To date, the experimental data are mainly obtained for the so-

called prismatic grasps in which the thumb opposes the fingers and the contact surfaces are

parallel (Figure 1). The contact forces and moments are typically recorded with 6-

component force and moment sensors.

Experimental ‘inverted-T’ handle/beam apparatus commonly used to study the prismatic

precision grip. Five six-component force sensors (black rectangles) are used to register

individual digit forces. During testing, the suspended load could vary among the trials. The

load displacement along the horizontal bar created torques from 0 N⋅m to 1.5 N⋅m in both

directions. The torques are in the plane of the grasp. While forces in all three directions were

recorded the forces in Z direction were very small and, if not mentioned otherwise, were

450

Parallel Manipulators, Towards New Applications

neglected. When the handle is oriented vertically the force components in the X and Y

directions are the normal and shear, (or tangential) forces, respectively. The figure is not

drawn to scale.

60 mm

Y

Z

Index

X

30 mm

Thumb

Middle

30 mm

Ring

30 mm

Little

Torque 0.0-1.5 Nm

Load 0.5 kg

Figure 1. Experimental ‘inverted-T’ handle/beam apparatus

2. Digit contacts

During an object manipulation the finger tips deform and the contact areas are not constant

(Nakazawa et al. 2000; Paré et al. 2002; Serina et al. 1997; Srinivasan, 1989; Srinivasan et al.

1992; Pataky et al. 2005). The fingers can also roll on the sensor surface. As a result, the point

of digit force application is not constant: it can displace by up to 5-6 mm for the fingers and

up to 11-12 mm for the thumb (Figure 2). Therefore the digit tip contacts should be as a rule

treated as the soft-finger contacts (Mason & Salisbury, 1985).

When a soft-finger model of the digit-object contact is employed, the contact is characterized

by six variables: three orthogonal force components (the normal force component is uni-

directional and the two tangential force components are bi-directional), free moment in the

plane of contact, and two coordinates of the point of force application on the sensor. To

obtain these data the six-component force and moment sensors are necessary. The

coordinates of the point of force application are not recorded directly; they are computed

from the values of the normal force and the moment around an axis in the contact plane.

Such a computation assumes that the fingers do not stick to the sensor surfaces, in other

words the fingers can only push but not pull on the sensors. In such a case the moment of

force about the sensor center is due to the application of the resultant force at a certain

distance from the center. The displacements of the points of digit force application change

the moment arms of the forces that the digits exert on the hand-held object and make the

computations more cumbersome.

Human Hand as a Parallel Manipulator

451

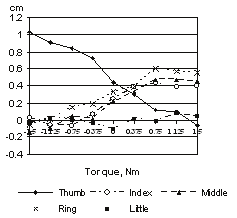

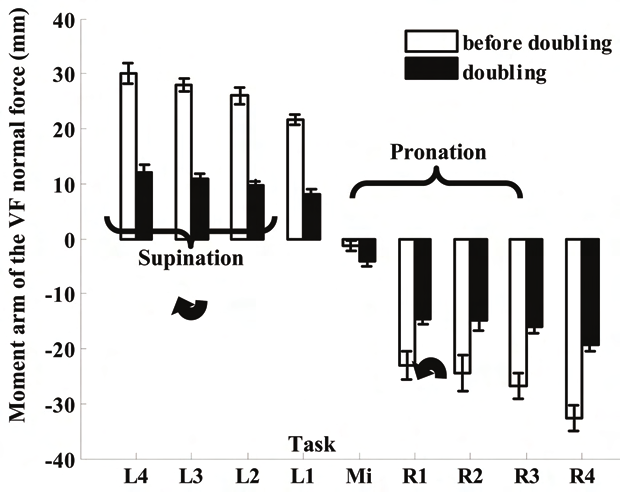

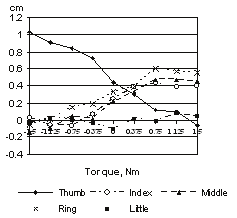

Figure 2. Displacement of the point of application of digit forces in the vertical direction at

the various torque levels. The results are for an individual subject (average of ten trials). The

positive direction of the torque is counterclockwise (pronation efforts), the negative

direction is clockwise (supination efforts). Adapted by permission from V.M. Zatsiorsky, F.

Gao, and M.L. Latash. Finger force vectors in multi-finger prehension. Journal of

Biomechanics, 2003a, 36:1745-1749.

3. Hand asymmetry and hierarchical prehension control

Asymmetry in the hand function is an important feature that differentiates the hand from

many parallel manipulators used in engineering as well as from some robotic hands (Fu &

Pollard 2006). The functional hand asymmetry is in part due to the hand design (e.g. the

thumb opposing other fingers, differences in the capabilities of index and little fingers, etc.)

and in part is due to the hand control.

Due to the specific function of the thumb opposing other fingers in grasping, the forces of

the four fingers can be reduced to a resultant force and a moment of force. This is

equivalent to replacing a set of fingers with a virtual finger, VF (Arbib et al. 1985, Iberall 1987;

Baud-Bovy & Soechting, 2001). A VF generates the same wrench as a set of actual fingers.

There are substantial differences between the forces exerted by individual fingers (IF) and

VF forces: (a) The IF force directions are as a rule dissimilar (for a review see Zatsiorsky &

Latash 2008) while their resultant (i.e., VF) force is in the desired direction (Gao et al. 2005).

(b) VF and IF forces adjust differently to modifications in task conditions (Zatsiorsky et al.

2002a, b). (c) IF forces are much more variable than VF forces (Shim et al. 2005a, b). The

desired performance at the VF level is achieved by a synergic co-variation among individual

finger forces at the IF level. The above facts support a hypothesis that multi-finger

prehension is controlled by a two-level hierarchical control scheme (reviewed in Arbib et al.

1985; Mackenzie & Iberall 1994). At the upper level, the required mechanical action on the

object is distributed between the thumb and the VF. At the lower level, action of the VF is

distributed among individual fingers.

452

Parallel Manipulators, Toward