z

Training to the highest level possible with available resources.

z

Submitting the unit’s status between regular reports, as required.

z

Ensuring the unit has computer hardware/software to process and submit the USR.

4-30. A unit’s C-level indicates the degree to which the unit has achieved prescribed levels of fill for personnel and equipment, the training status of those personnel, and the maintenance status of its equipment. Detailed procedures for reporting C-level are contained in AR 220-1.

ASSESSING AND REPORTING UNIT PROFICIENCY

4-31. As indicated earlier, the unit’s METL is derived from an analysis of the assigned wartime missions and is approved by its next higher headquarters in the reporting chain of command. The commander, at all levels, assesses the unit’s ability to execute mission essential tasks to standard. Commanders consider the unit’s ability to perform in unique operational environments as required by the unit’s METL. When assessing ATS unit proficiency, commanders use personal observations, records, reports and the assessments of others (internal and external to the unit). The commander considers the demonstrated proficiency of subordinate elements, leaders, and Soldiers; and the availability of critical resources required to support METL training as follows:

z

The unit and organic sub-elements demonstrate proficiency during external evaluations of ARTEP/MTP standards; deployment at collective training centers; emergency deployment readiness, field training, CP, combined arms live-fire, and operational readiness exercises; and other training events described in the unit’s CATS. Proficiency is measured in terms of the unit’s demonstrated ability to perform the tasks as stated in the approved METL, including supporting tasks not specified in the METL but necessary for performing METL tasks. Proficiency is judged on the performance of these tasks to standard. Full METL proficiency is achieved when a unit has attained a trained/T level of proficiency in all METL tasks as defined in FM 7-1. Sustaining proficiency then becomes the commander’s challenge.

z

Leader qualification includes not only those areas of training required by their base branch, but also those areas required by professional leadership development programs supporting the unit’s mission.

4-32. In addition to maintaining a minimum number of qualified air traffic controllers and ATS

maintenance personnel to perform most of the critical warfighting tasks to standard, commanders must satisfactorily accomplish collective training events as defined in the appropriate CATS. Commanders perform T-level assessments per AR 220-1 to review and confirm the results of their T-level assessments in light of their unit’s accomplishments during critical training events. The T-level rating provides meaningful information for the entire chain of command. The ATS unit training T-level is a major factor in determining how many days the unit needs to train to standard on METL tasks. Additionally, this T-level provides an indicator to the aviation commander and staff on aircraft support requirements to achieve training goals of the ATS company. Commanders use the number of days the unit needs to train to standard 16 February 2007

FM 3-04.120

4-7

Chapter 4

METL tasks, along with the information in AR 220-1 to determine the overall T-level. The following guidelines apply to T-level requirements for ATS units—

z

T-1. At least 85 percent of air traffic controllers and ATS maintenance personnel are RL-1.

z

T-2. At least 65 percent of air traffic controllers and ATS maintenance personnel are RL-1.

z

T-3. At least 50 percent of air traffic controllers and ATS maintenance personnel are RL-1.

z

T-4. Less than 50 percent of air traffic controllers and ATS maintenance personnel are RL-1.

4-33. The use of RLs does not supersede ATC training time limitations or rating/certification system requirements detailed in AR 95-2, FAA orders, and other appropriate maintenance and air traffic control guidelines. Commanders and examiners should develop ATTPs and AMTP’s consistent with training time limitations contained within these documents.

4-34. The guidelines detailed should serve as a training indicator for controller and ATS maintenance personnel qualifications as they relate to the units overall ability to accomplish assigned mission(s).

Commanders and leaders must continually assess the environment and make determinations on individual skill proficiency required to safely execute aviation operations. Commanders should always consider minimum operating requirements and maximum hours of operation (fighter management/crew rest) for the safe operation of air traffic systems.

SECTION V – ADDITIONAL TRAINING CONSIDERATIONS

4-35. ATS leaders must keep in mind ATC skills are a challenge to train in tactical ATS units and extremely perishable. The crew-level training progression of the aviation brigade does not inherently support the traffic density requirements to train and sustain air traffic controllers of many ATS units. It remains critical that ATS leaders maximize opportunities to participate in the collective training events of the aviation brigade.

4-36. ATS leaders should explore other training opportunities with installation ATC facilities within their geographical area. ATS units fostering relationships and training opportunities with installation ATC

facilities are uniquely better prepared to execute ATS operations in heavy air traffic environments.

Likewise, ATS maintenance should not be excluded from installation training partnerships. Training on the NAVAIDs and radio systems employed by installation ATC facilities may significantly increase the skills and abilities of ATS maintainers.

4-8

FM 3-40.120

16 February 2007

Chapter 5

Maintenance Operations

Repairing equipment far forward enhances the ability to quickly return the maximum number of systems at the earliest opportunity. The concept of replacing components and modules instead of repairing them is a key element in the logistic support and maintenance operations of all modern ATS systems. This concept leverages advanced prognostics and diagnostic tools, support equipment, and training of ATS

maintainers.

SECTION I – UNIT-LEVEL MAINTENANCE

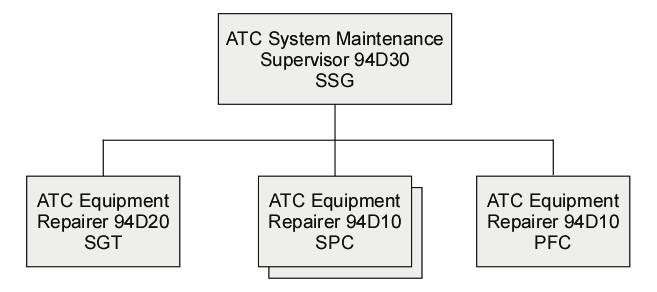

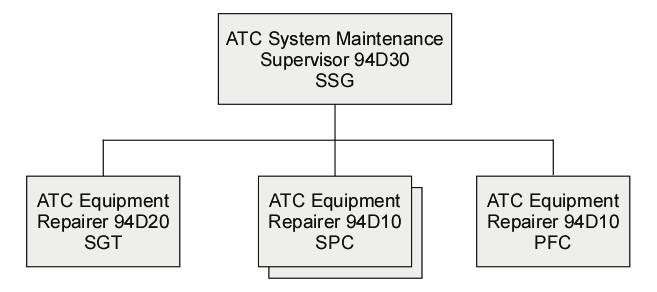

5-1. The COMNAV maintenance section of the

GSAB ATS company and AOB are the maintenance

Contents

enablers of the air traffic mission area. ATS

maintainers not only execute field-level Section I – Unit-Level Maintenance..........5-1

maintenance, but also perform sustainment-level Section II – External Maintenance maintenance actions on air traffic systems. This

Organizations .........................................5-3

unique replace and fix forward capability ensures Section III – Additional Maintenance critical systems are available to accomplish the

Considerations.......................................5-5

multitude of ATS missions assigned to air traffic

organizations. Figure 5-1 illustrates the COMNAV

section organized under the GSAB ATS company and AOBs.

Figure 5-1. COMNAV section

TWO-LEVEL MAINTENANCE OPERATIONS

5-2. During the past decade, the United States Army has been engaged in a deliberate and seeping effort to adapt its organizations, Soldiers, equipment, and methods or operations to requirements of a rapidly changing strategic and technological landscape. The power of advanced technologies, especially information technology, enables the Army to achieve situational dominance and decision-making momentum, creating a new construct for the application of force.

5-3. The Army vision calls for transforming from a forward-deployed force to a strategically responsive force projection Army. Today’s reactive maintenance system creates a large battlefield logistical footprint reliant on multiple headquarters to coordinate forward support activities and evacuation of inoperative 16 February 2007

FM 3-04.120

5-1

Chapter 5

systems. The current methodology of “fix forward” is changing to a “replace forward-repair rear”

methodology. Clearly, the skills and abilities of our ATS maintainers executing this shift in doctrine will also change.

5-4. The air traffic maintenance program is aligned with the Army maintenance system detailed in AR 750-1 and FM 4-30.3. Unique to the ATS maintenance strategy is the alignment of repair functions for both field and sustainment-level maintenance. Field maintenance, also known as on-system maintenance, is primarily associated with repairs that return equipment to operators. Sustainment maintenance, also known as off-system maintenance, primarily repairs and returns equipment to the supply system. Each of these functions is supported by ATS maintainers.

5-5. ATS maintainers perform the following maintenance actions under field maintenance—

z

Preventive maintenance checks and services (PMCS).

z

Inspections by sight and touch of accessible components per the TM XX-10 series and condition-based maintenance indicators or instrumentation.

z

Lubrication, cleaning, preserving, tightening, replacement, and minor adjustments.

z

Limited diagnosis and fault isolation.

z

Replacement of combat spares.

z

Requisition, receipt, storage, and issue of repair parts.

z

Evacuation to the appropriate maintenance support activity of unserviceable reparables.

z

Coordination and transportation of ATS systems.

z

Materiel readiness reporting.

z

Fabrication as identified by the appropriate TM.

5-6. ATS maintainers perform the following maintenance actions under sustainment maintenance—

z

Inspection, diagnosis, isolation, and repair of faults within modules and components.

z

Turn-in of unserviceable end items and components through the appropriate supply activity.

z

Fabrication or manufacture of repair parts, assemblies, components, jigs, and fixtures.

z

Equipment modifications as required by AR 750-10.

z

Manufacturing of end items and parts not provided or stocked by the national supply system.

z

Special inspections and modifications of equipment requiring extensive disassembly or elaborate test equipment.

z

Nondestructive testing to determine the acceptability of removed parts.

z

Installation of all outstanding modification work orders and minor alterations directed by the materiel proponent.

z

Postproduction software support, the sustainment of the operational software embedded in weapon systems after closure of the production line.

Note: In accordance with AR 750-1, modified table of organization and equipment (MTOE) ATS maintenance personnel may perform duties at table of distribution and allowances (TDA) maintenance activities to maintain skills and update MOS training.

POSITIONING MAINTENANCE SUPPORT ASSETS

5-7. The nature of the modern battlefield demands that ATS systems be repaired quickly and as far forward as possible. This requirement implies a forward thrust of maintenance within the division AO.

Maintenance assets move as far forward as the tactical situation permits, repairing unserviceable and damaged ATS systems to return them as quickly as possible.

5-8. A viable maintenance system complements the capabilities of the supply system. When equipment is in short supply or unavailable to support requirements, commanders use the maintenance system to offset 5-2

FM 3-04.120

16 February 2007

Maintenance Operations

the shortfall. Equipment has become complicated and technically advanced, making it easier to meet surge requirements by redirecting the maintenance effort rather than influencing the supply effort.

5-9. The job of maintenance managers is to ensure the proper mix (type and location) of maintenance that best supports the commander’s tactical and operational requirements. Early movement of essential maintenance capabilities ensures that deployed ATS systems are operational upon arrival in a theater of operations.

SPLIT-BASED OPERATIONS

5-10. Split-based operations refer to performing certain logistic and maintenance functions within a given theater of operation, in more than one location. This is a principal concern of the COMNAV section due to the nature of ATS operations within the CAB and additional ATS maintenance support to the brigade aviation element and division airspace cell. By all accounts, this is the most significant challenge of the ATS COMNAV section. Commanders must develop detailed plans and support agreements between supported elements/staffs of their respective commands to ensure timely repair of ATS systems emplaced throughout the battlefield.

5-11. Strategic split-based operations refer to performing certain logistic and maintenance administrative and management functions outside the joint operations area (JOA). These functions can be performed in a secure theater location, an ISB, or home station. Soldiers and civilians can perform personnel, materiel, and distribution management functions without deploying to the JOA if standard Army management information systems (STAMIS) are adequate. The STAMIS help minimize strategic lift requirements and reduce the sustainment footprint in theater while still meeting support requirements.

CONTRACT AND CIVILIAN MAINTENANCE SUPPORT

5-12. AR 750-1, AR 70-1, and AR 700-127 contain policy guidance on the utilization and employment of contractors, DA civilians, and local national augmentation used for supporting Army operations.

Specifically, AR 750-1 details the utilization of military and non-military personnel in maintenance operations with the following:

z

Military personnel will perform maintenance in combat or hazardous duty areas as much as possible. The employment of civilians in hazardous duty areas for the performance of maintenance of field equipment that can be maintained by a Soldier is strongly discouraged.

z

Civilians will not be permanently stationed in combat areas or hazardous duty areas as determined by the combatant commander (see AR 715-9). Civilians may travel forward to a brigade combat team operational area on a case-by-case basis as individual equipment failures occur to provide temporary onsite maintenance and technical advice (sustainment-level maintenance assistance teams and/or modification application teams).

z

Outside the brigade operational area, in addition to military personnel, civilian maintenance personnel (contract, TDA, local nationals, and so on) may be acceptable as a prudent risk on the probability of maintenance services being continued in wartime and in support of other operations.

5-13. Certification is the quality control used by ATS maintainers to ensure ATS systems are operating with required parameters. Independent discretionary judgment about the provision of services, the need to separate profit motivations from operational decisions, and the desire to minimize liability, make the regulatory function of certification and oversight inherently a governmental function. Contractors and host nation augmentation will not be used in the certification or verification of ATS systems, NAVAIDS, and ATS maintenance training programs.

SECTION II – EXTERNAL MAINTENANCE ORGANIZATIONS

5-14. Sustainment maintenance support is divided and primarily performed by three separate entities: the original equipment manufacturers (OEMs), their civilian field service representatives (CFSRs), and Army depots. These Army depots, located at fixed bases in CONUS, are the national maintenance sources of 16 February 2007

FM 3-04.120

5-3

Chapter 5

repair (SORs). Sustainment maintenance supports the supply system by economically repairing or overhauling components.

5-15. Sustainment maintenance refers to all maintenance performed on equipment above and outside of the combat aviation brigade. The OEM CFSRs may be placed within the combat aviation brigade to provide a limited forward sustainment maintenance capability. They operate out of fixed or semi-fixed facilities.

ATS MAINTENANCE COMPANY–FORSCOM

5-16. A deployable special repair activity with mobile maintenance contact teams is organized under the FORSCOM aligned Ordnance Branch. This company operates a supply support activity and provides class IX materiel support for tactical ATS systems worldwide. This organization executes general support/limited depot ATS maintenance operations in CONUS and through deployed ATS maintenance teams in the theater of operation.

UNITED STATES ARMY MATERIEL COMMAND

5-17. The United States Army Materiel Command’s (USAMC’s) mission is complex and ranges from developing sophisticated weapon systems to maintaining and distributing spare parts. The USAMC’s mission is to provide superior technology, acquisition support, and logistics. The USAMC operates the research, development and engineering centers; Army Research Laboratory; depots; arsenals; ammunition plants; and other facilities. Subordinate commands provide specific aviation support within the USAMC

structure. These commands include the United States Army Aviation and Missile Command (AMCOM) and United States Army Communications-Electronics Command (CECOM).

5-18. The USAMC—

z

Overhauls and upgrades Army equipment during the reset phase of the Army force generation (ARFORGEN) process.

z

Produces and provides bombs and ammunition for all military services.

z

Provides on-the-ground logistics assistance to every unit in the Army.

z

Provides new equipment training.

z

Maintains the Army's pre-positioned stocks on land and at sea.

z

Researches, develops, and acquires conventional ammunition for DOD.

z

Supports acquisition of end items and parts for military weapon systems.

CECOM

5-19. The CECOM mission is to develop, acquire, and sustain superior information technologies and integrated systems. CECOM controls and operates Tobyhanna Army Depot.

5-20. This particular depot is the largest, full-service electronics maintenance facility within DOD. Its mission is total sustainment, including design, manufacture, repair, and overhaul of hundreds of electronic systems. These include satellite terminals, radio and radar systems, telephones, electro-optics, night vision and anti-intrusion devices, airborne surveillance equipment, navigational instruments, electronic warfare, guidance and control systems for tactical missiles, and BFT installation kits.

UNITED STATES ARMY AVIATION AND MISSILE COMMAND

5-21. AMCOM is a major subordinate command of the USAMC. AMCOM has direct operational control of the national maintenance SOR and two Army depots: Corpus Christi Army Depot and Letterkenny Army Depot.

5-4

FM 3-04.120

16 February 2007

Maintenance Operations

NATIONAL MAINTENANCE SORS

5-22. The national maintenance manager is responsible for managing all sustainment-level reparables and selected field-level reparables according to AR 750-1. The national maintenance manager uses various sources of repair. The national maintenance program distributes sustainment maintenance workload across depot and nondepot activities based on national needs. The national maintenance program manager may establish the use of a theater aviation sustainment manager within a specific theater. The theater aviation sustainment manager provides a unified aviation maintenance life-cycle management command focused on the use of theater assets, providing airframe maintenance, overhaul of aviation subassemblies, and crash/battle damage repair.

5-23. Performance-based logistics (PBL) is a support strategy that places primary emphasis on optimizing system support to meet the needs of the warfighter. Its primary tenets are documentation of warfighter performance requirements as measurable metrics in performance-based agreements designation of single point accountability for performance with a product support integrator and development of support metrics and accompanying incentives to ensure that the performance objectives are met. In short, PBL is buying performance, not transactional goods and services. PBL delineates outcome performance goals of systems; ensures that responsibilities are assigned; provides incentives for attaining these goals; and facilitates the overall life-cycle management of system reliability, supportability, and total ownership costs. It is an integrated acquisition and logistics process for buying system capability.

5-24. Source-of-support decisions for PBL do not favor either organic or commercial providers. The decision is based upon a best value analysis or business case analysis of the provider's product support capability to meet set performance objectives.

5-25. Depot level maintenance includes the repair, fabrication, manufacture, rebuilding, assembly overhaul, modification, refurbishment, rebuilding, test, analysis, repair-process design, in-service engineering, upgrade, painting and disposal of parts, assemblies, subassemblies, software, components, or end items that require shop facilities, tooling, support equipment, and/or personnel of higher technical skills, or processes beyond the organizational level capability. Depot level maintenance can be independent of the location at which the maintenance or repair is performed, the source of funds, or whether the personnel are government or commercial (contractor) employees.

SECTION III – ADDITIONAL MAINTENANCE CONSIDERATIONS

ARMY WARRANTY PROGRAM

5-26. The Army warranty program covers all items procured for Army use purchased with an accompanying warranty. This program includes aircraft, aircraft weapon systems, ATS systems, repair parts and components. The Army also purchases warranties for items such as trucks, tractors, engines, transmissions, and construction equipment.

Note: Refer to AR 700-139 for additional guidance on the Army’s warranty program.

5-27. ATS units receiving newly fielded equipment and components should check to see what type of warranty the Army purchased for their newly fielded equipment. Tailoring the warranty concept to fit the item and its intended use in a comprehensive manner with minimal effect on standard Army logistical procedures is the single most important aspect of the warranty acquisition process. Warranty tailoring is intended to protect the Army from the costs and frequency of systemic failures and to enact responsive remedies for failures of significant operational effect on aircraft readiness.

5-28. When newly fielded equipment under warranty experiences a malfunction, aviation maintenance officers/technicians should request assistance from the logistics assistant program (LAP) office for answers to or resolution of warranty issues or questions.

16 February 2007

FM 3-04.120

5-5

Chapter 5

5-29. Logistics assistant officers (LAOs) or logistics assistant representatives provide advice and assistance to the Army command warranty claims officer (WARCO) and aviation unit maintainers as part of their service interface as established in AR 700-4. Representatives of the LAP will—

z

Clarify warranty applications/exclusions and warranty claim/report procedures upon user or WARCO request.

z

Provide warranty information to users/WARCOs as a secondary source of information.

z

Provide specific assistance as outlined in materiel fielding plans and technical and supply bulletins/manuals and related documents for warranty management.

5-30. ATS equipment and components covered by the Army warranty program require special handling during the warranty period to keep it valid. Details concerning warranty provisions are published in supply letters. The WARCOs or LAOs will have a copy of the warranty supply letter on items within their area of support. Warranties will increase the time required to perform maintenance.

5-31. Once assistance and guidance is received from LAP technical representatives and warranty issues and concerns are addressed and resolved, aviation unit maintenance personnel shall submit a product quality deficiency report. DA Pamphlet 738-751 provides procedural guidance and information for this report.

NEW EQUIPMENT TRAINING TEAMS

5-32. The Logistics Assistance and New Equipment Training Division is one of the subordinate divisions of the Directorate for Readiness. Its mission is staff supervision and operational control of worldwide LAPs for Army ATS systems and related support equipment. The division also provides representatives to make command visits and manage all aspects of the new equipment training and support services.

ARMY TEST, MEASUREMENT, AND DIAGNOSTIC EQUIPMENT

5-33. United States Army test, measurement, and diagnostic equipment (TMDE) is essential to ATS

maintenance due to its distinctive ability to test, adjust, synchronize, repair, and verify accuracy, safety, readiness, and information assurance of ATS systems. The capability of ATS systems, radios and communication devices to operate accurately and effectively depends on the synchronization of precise measurements against known standards.

5-34. AR 750-43 assigns management of the TMDE calibration and repair support program to Headquarters, Air Mobility Command. In turn, the TMDE activity is responsible for DA TMDE program execution and management. National Guard Bureau is assigned management, command, and control over Army National Guard (ARNG) maintenance companies and their assigned TMDE. It also controls calibration facilities at combined support maintenance shops. AR 750-43 prescribes policies and procedures, assigns responsibilities, and establishes goals and objectives applicable to the development, selection, acquisition, management, sustainment, and support of Army TMDE, associated test program sets, embedded diagnostics and prognostics, and interactive technical manuals.

5-6

FM 3-04.120

16 February 2007

Appendix A

Deployment-Redeployment Life-Cycle

This appendix addresses deployment of ground vehicles and equipment. The

capability to quickly and safely deploy ATS assets from CONUS or forward-

deployment sites to another theater of operation is critical. Units that plan, train, and validate movement strategies increase chances of success.

FUNDAMENTALS

A-1.