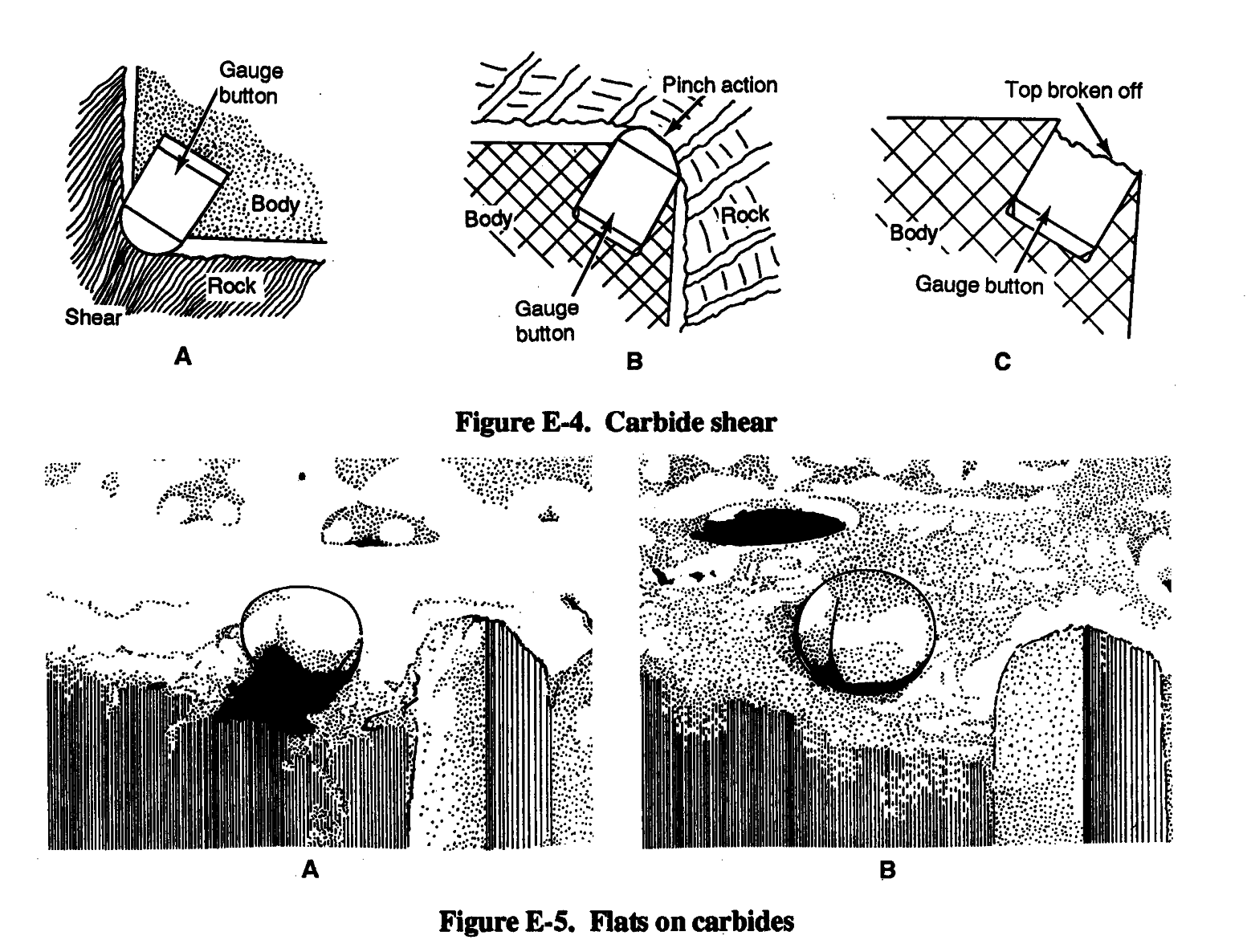

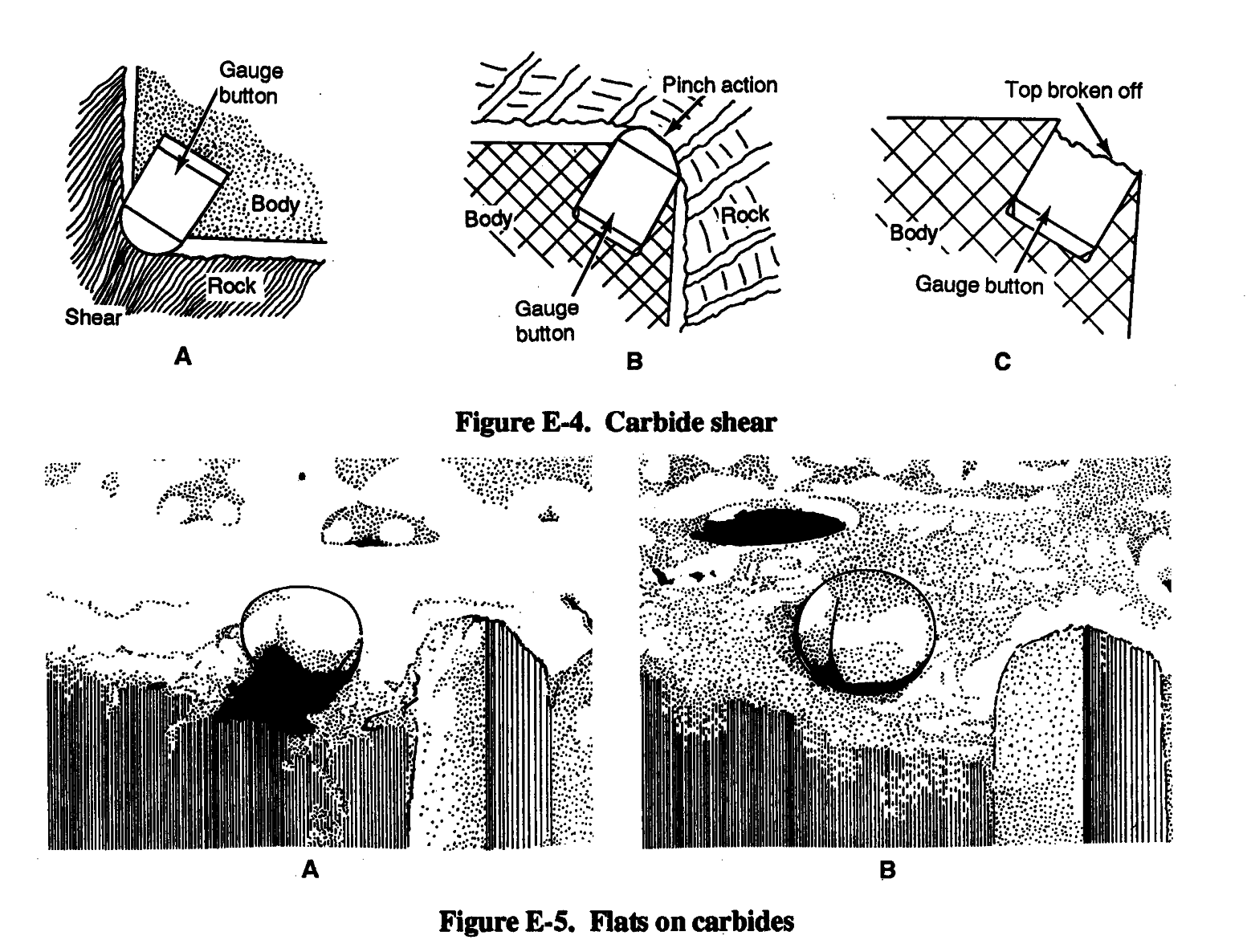

Buttons must be ground to restore their original shape at

the first sign of a developing flat. High rotation speeds tend to accelerate the development of flats on the carbide. Although RPM will vary with local conditions, rotating the bit faster will not increase

the penetration rate but will increase the chances of shearing a carbide (Figure E-5, B).

E-2

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

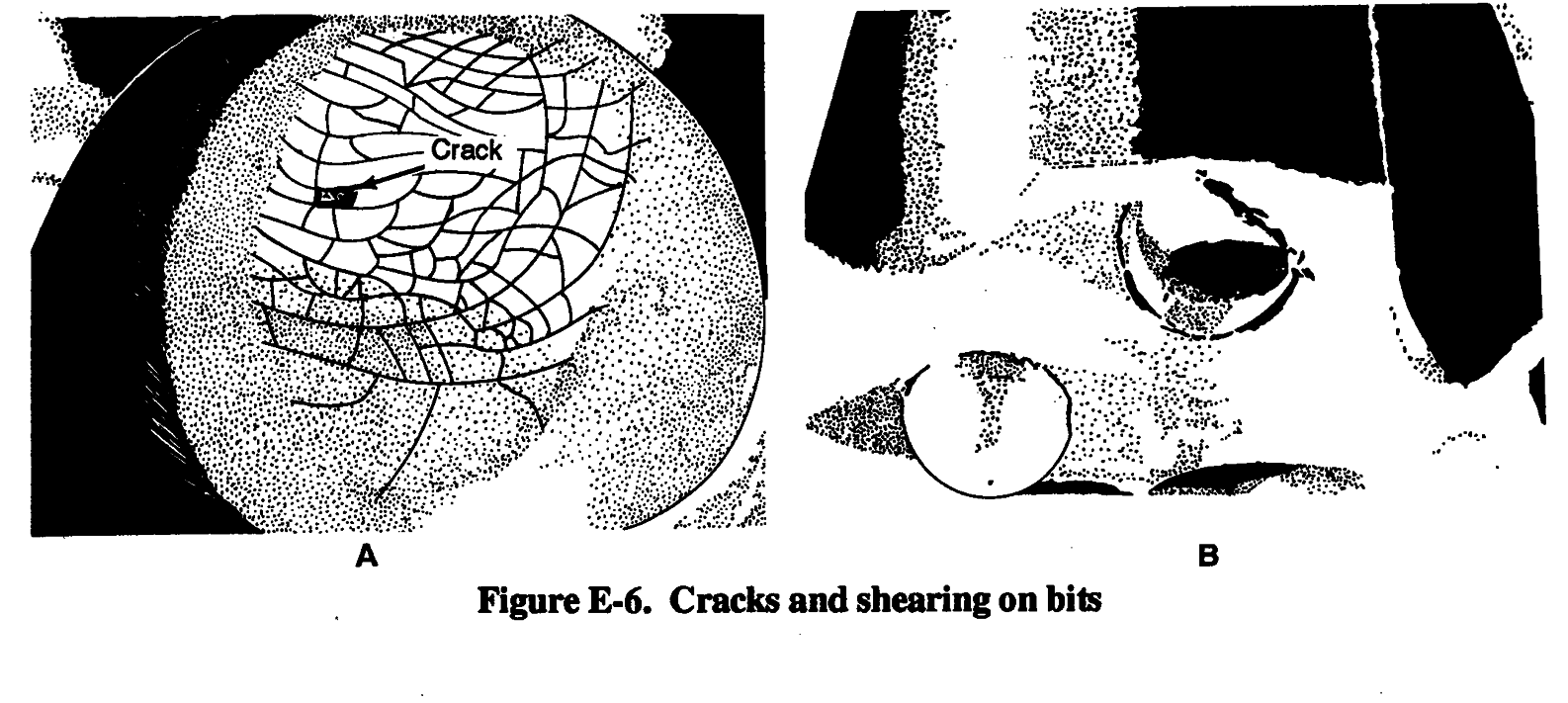

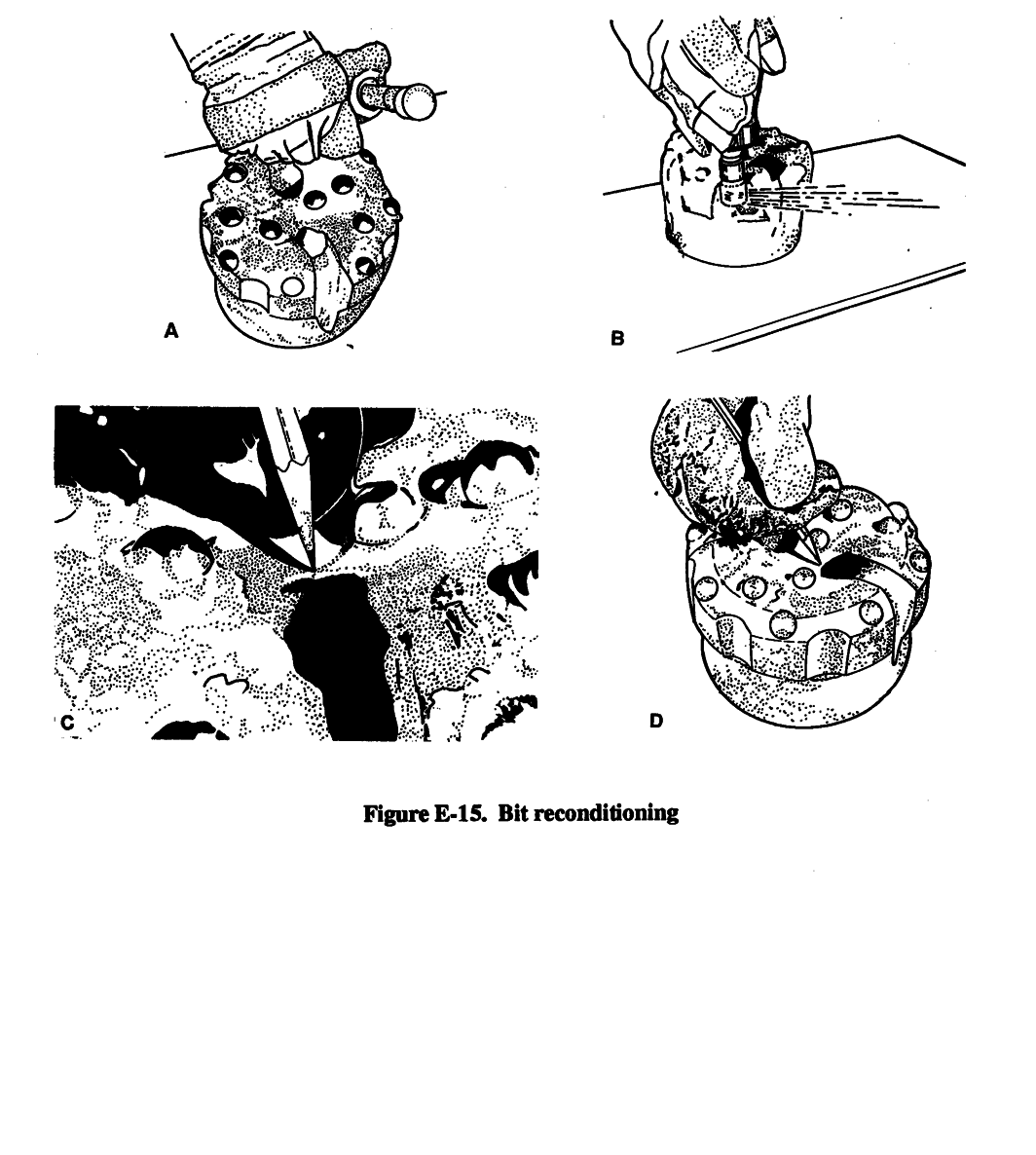

Progressive heat checking in the developed flats indicates excessive RPM. Small cracks (Figure E-6, A) develop on the face of the flat and if not reconditioned, breakdown of the button continues until it finally splits. The button then shears off and the effectiveness of the bit is lost (Figure E-6, B). A good rule of thumb is to rotate at the lowest RPM that permit smooth operation.

E-3

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

Another condition that can result in carbide shear is drilling through bent casing (Figure E-7, A). A bent casing will cause the carbides to be pinched as the drill string passes through it and the carbide breaks as a result. Also, when changing bits after starting a hole, do not put a larger bit into an existing smaller diameter hole. Always measure bit gauge and use the larger bit first to prevent pinching the gauge carbides (Figure E-7, B).

After many hours of drilling in

nonabrasive soft rock the carbide begins to

fatigue. A network of fine cracks appear

and small flecks of carbide break away

(Figure E-8). The buttons have a polished

effect with no flats, and there is minimum

abrasive wear on the bit body. If not

checked, this will lead to further

breakdown of the carbide, side loading, and

carbide shear. To prevent this type of

failure in soft formation drilling,

reconditioning must be scheduled at

intervals that do not exceed 10 percent of

the overall life expectancy of the bit.

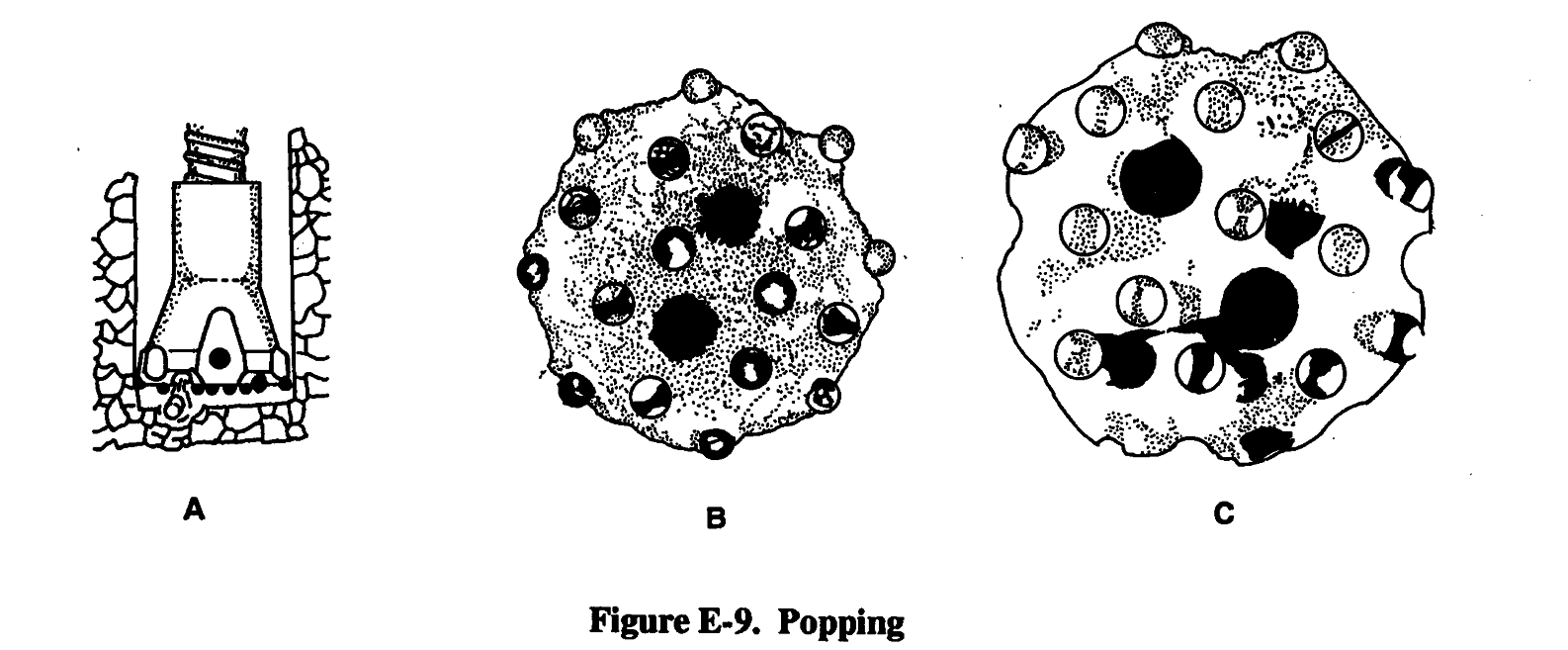

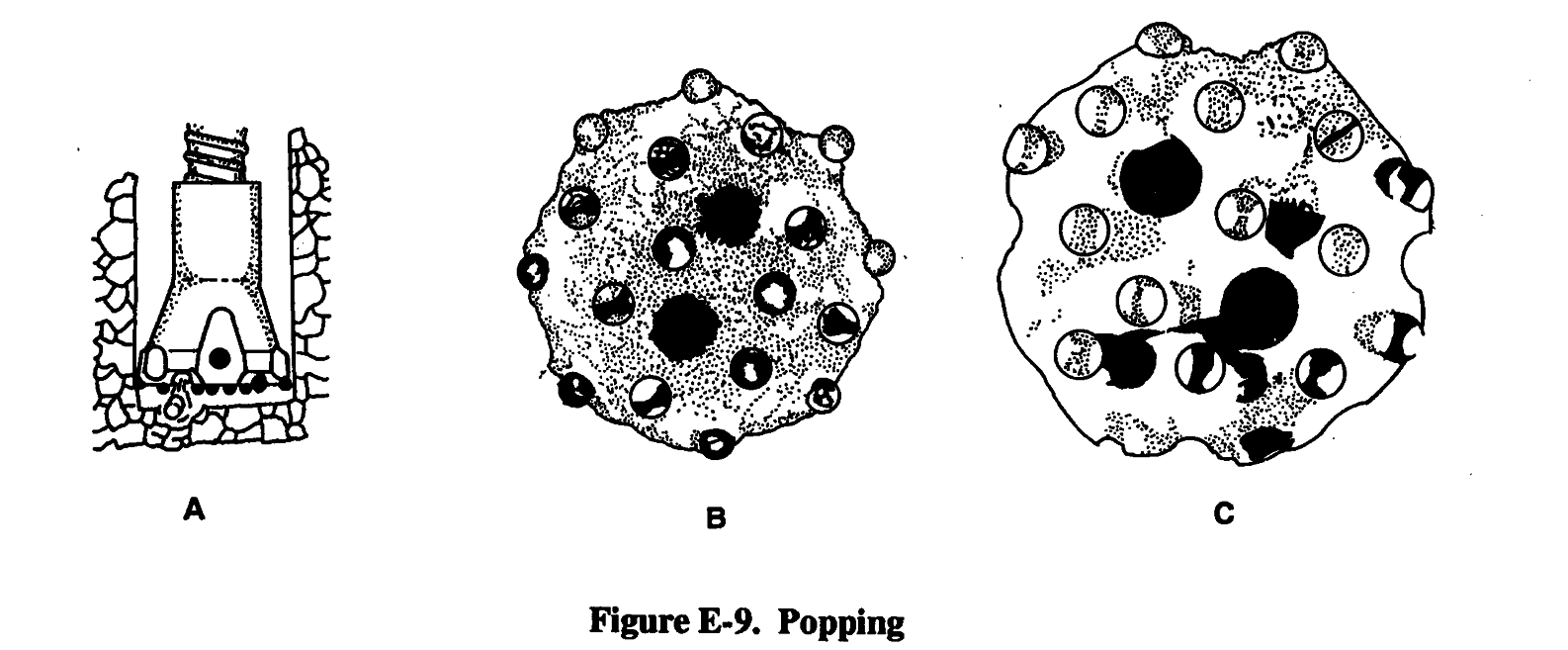

Popping of carbide inserts is a result of loose running. A carbide will pop clean from its socket

if the drill string is not properly fed up in the hole (Figure E-9, A). This is most common in

overburden drilling or in broken and unconsolidated formations. A large amount of energy is produced from the piston striking the shank in drifter drilling or the bit in down-hole drilling if the bit is not fed up to the rock. Instead of breaking the rock, this energy is retained in the bit and will

cause the carbides to pop (Figure E-9, B). When body metal around the carbide becomes too weak

due to overrunning the bit without proper grinding, the buttons pop out (Figure E-9, C). This greatly

—

reduces the life of the bit.

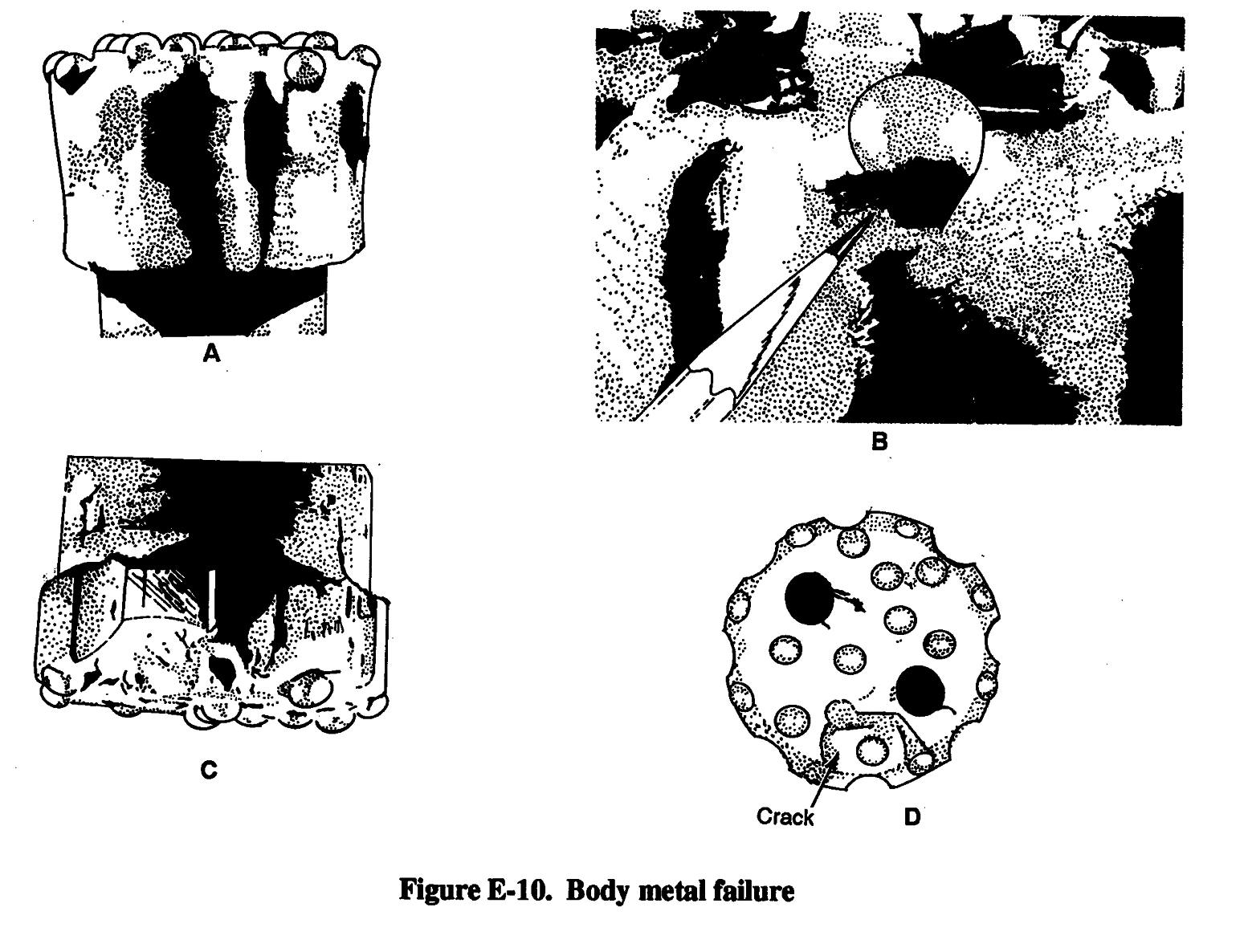

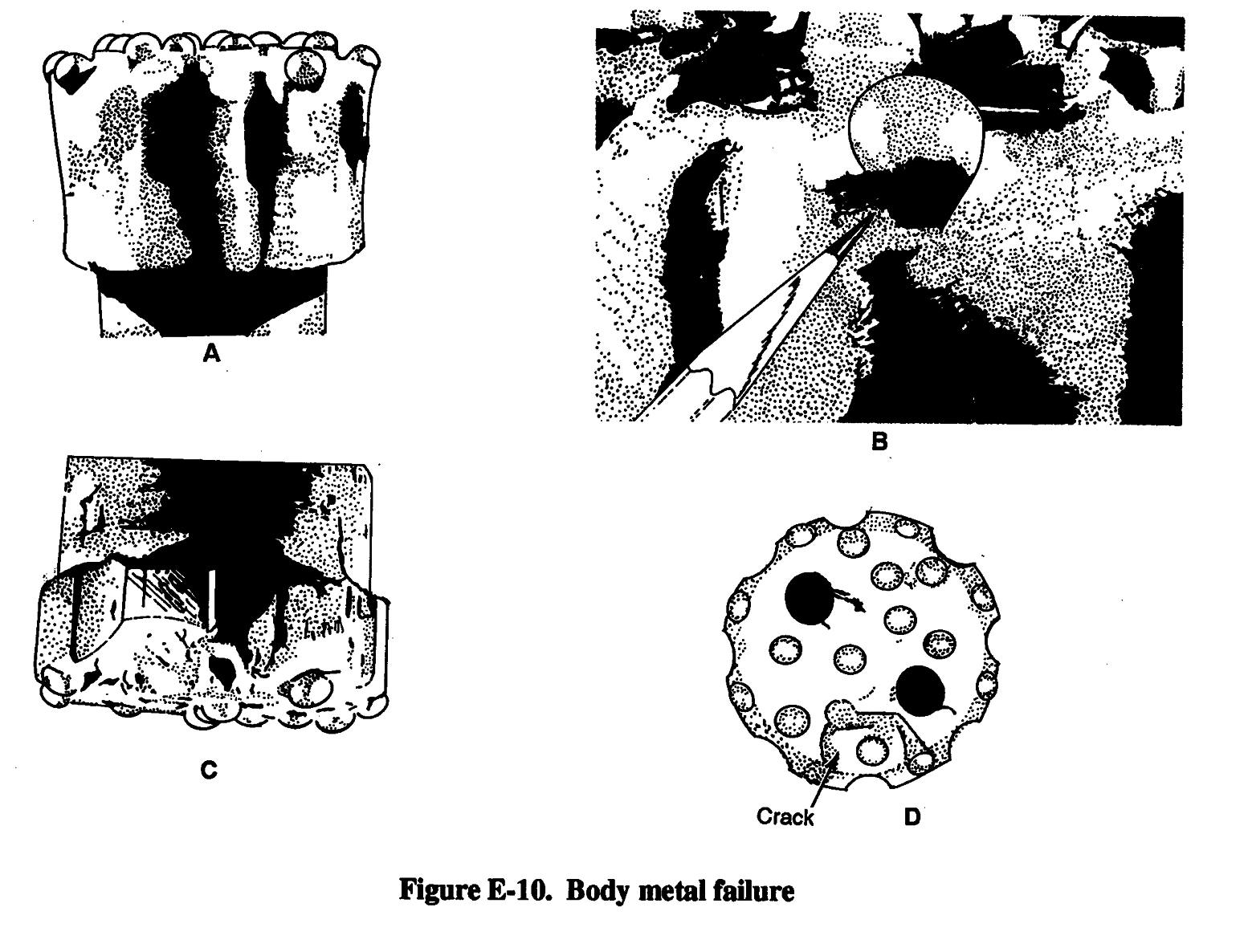

Body metal is another type of bit failure. Figure E-10, A shows a condition called body wash

(eroded body metal). Figure E-10, B shows the lip next to the button and the extent to which the

E-4

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

button is protruding. The combination of a flat carbide and a large beam of exposed carbide generates side loading which fatigues the base in which the button rests. Figure E-10, C shows that the carbide and body have separated just below the rim of the socket while a fatigue crack has developed in the body metal. Cracks in the body (Figure E-10, D) can lead to entire pieces of the bit shearing off.

E-5

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

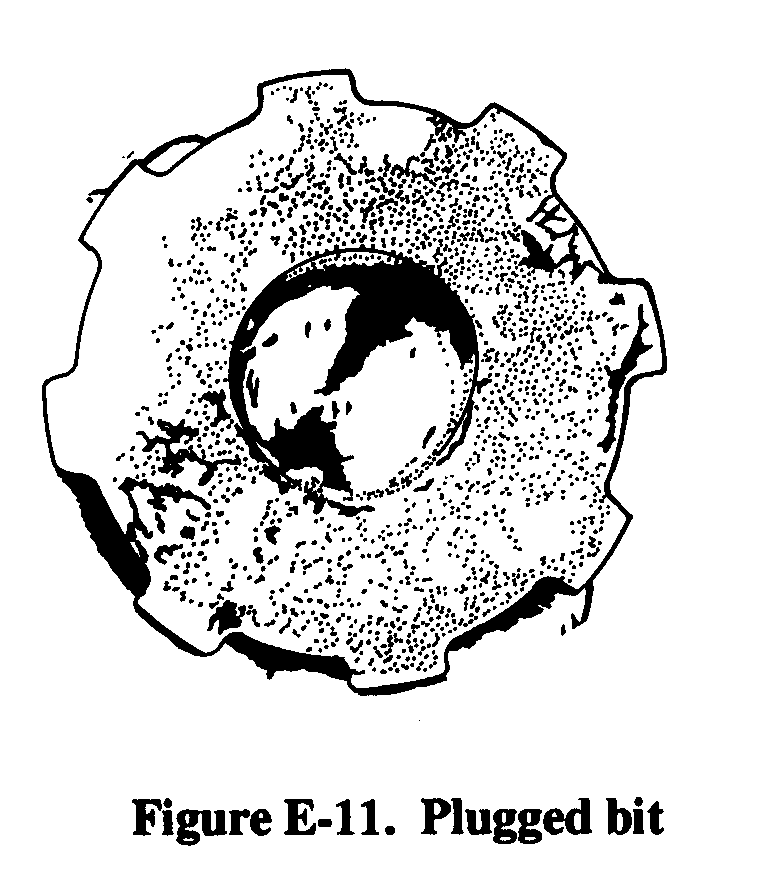

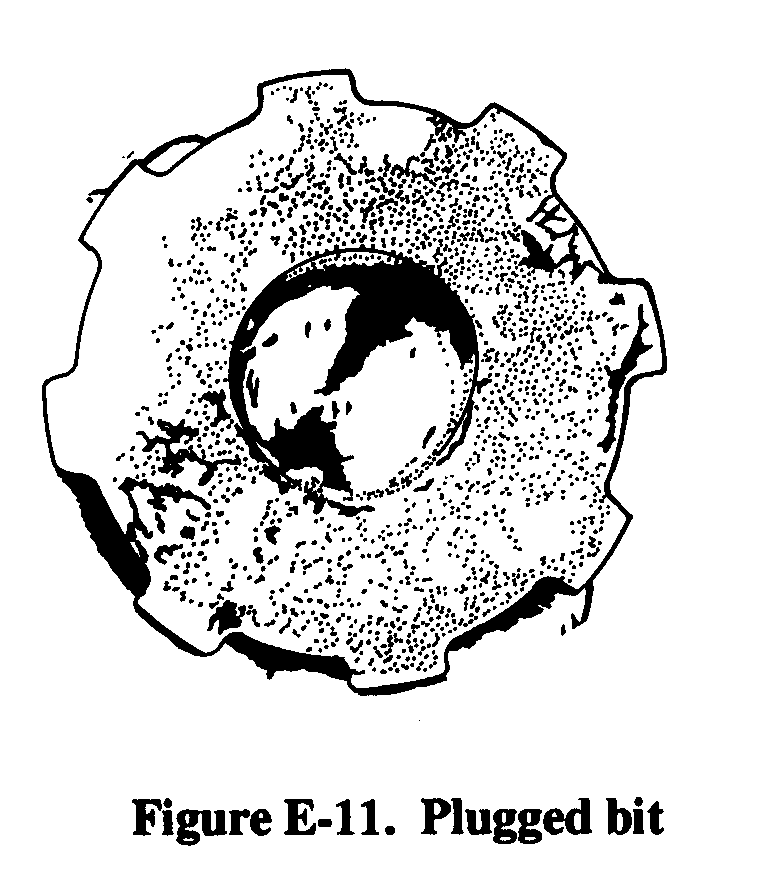

For optimum performance, introduce a bit to new rock regularity. If cuttings remain in the hole, the energy to break new rock is not transferred, putting undue stress on the bit, the drill, and the drill string. Each component will undergo more unnecessary stress and will fatigue faster and fail earlier. Figure E-11 shows an extreme example of what will happen if air is not continually fed down the hole. This bit has been plugged solid by the cuttings.

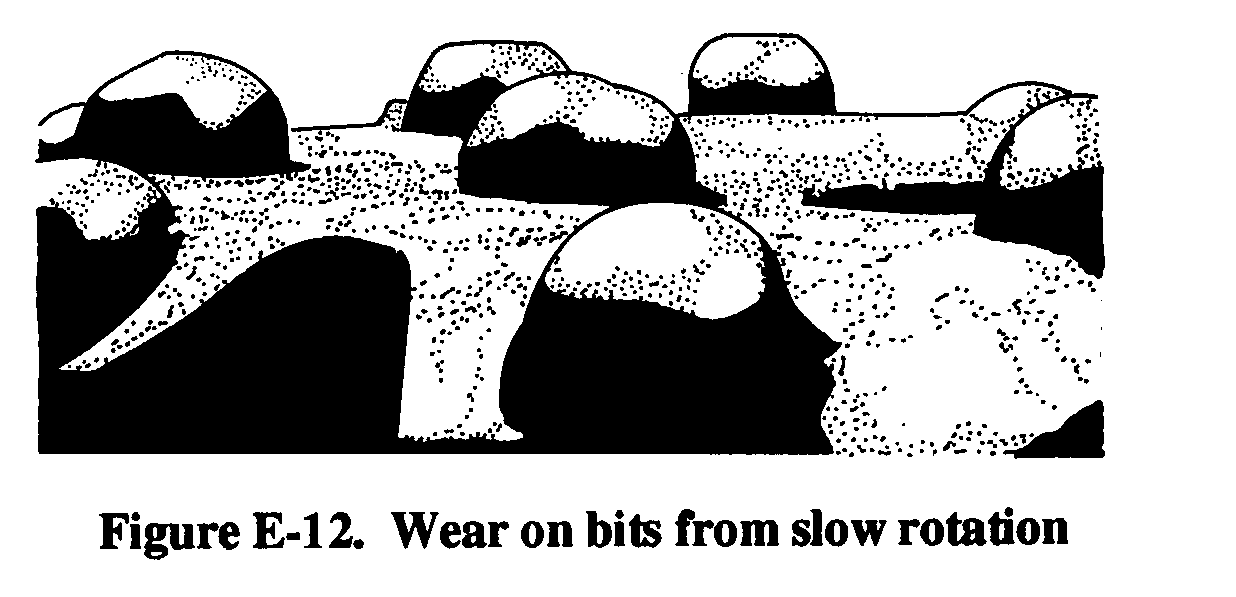

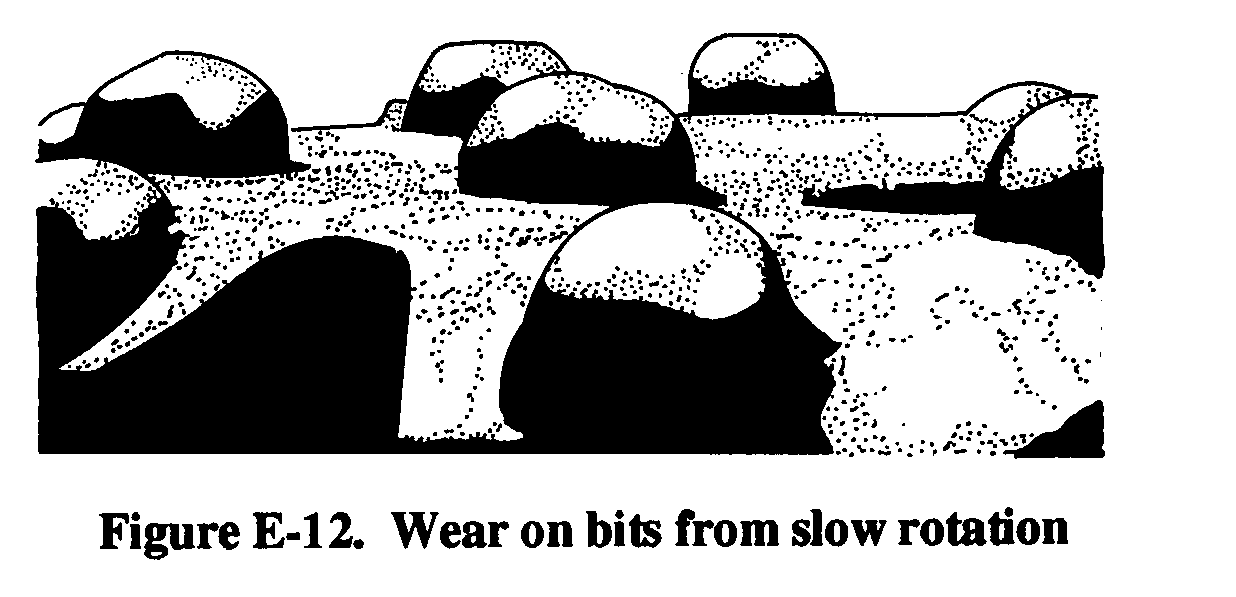

If rotation is too fast, flat spots, heat checks, and shearing will occur. If rotation is too slow, lopsided wear on the

carbides will occur. Figure E-12 shows a bit that has been

rotated too slowly. The button is barely out of the impression it made with the previous impact, when it is struck again.

Undue wear is caused on one side of the button, creating a

point on the carbide. When the point is sharp enough, it

chips, or portions of the button break away.

E-3. Reconditioning. The following lists some suggested equipment necessary for proper bit reconditioning:

A bit-grinding stand and a vitrified silicon carbide wheel that is 1 inch by 1 inch in diameter and rated at 25,000 RPM.

An I-R DIR DG121 grinder or its equivalent.

Safety glasses, hard hat, ear protection, and gloves

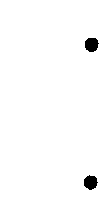

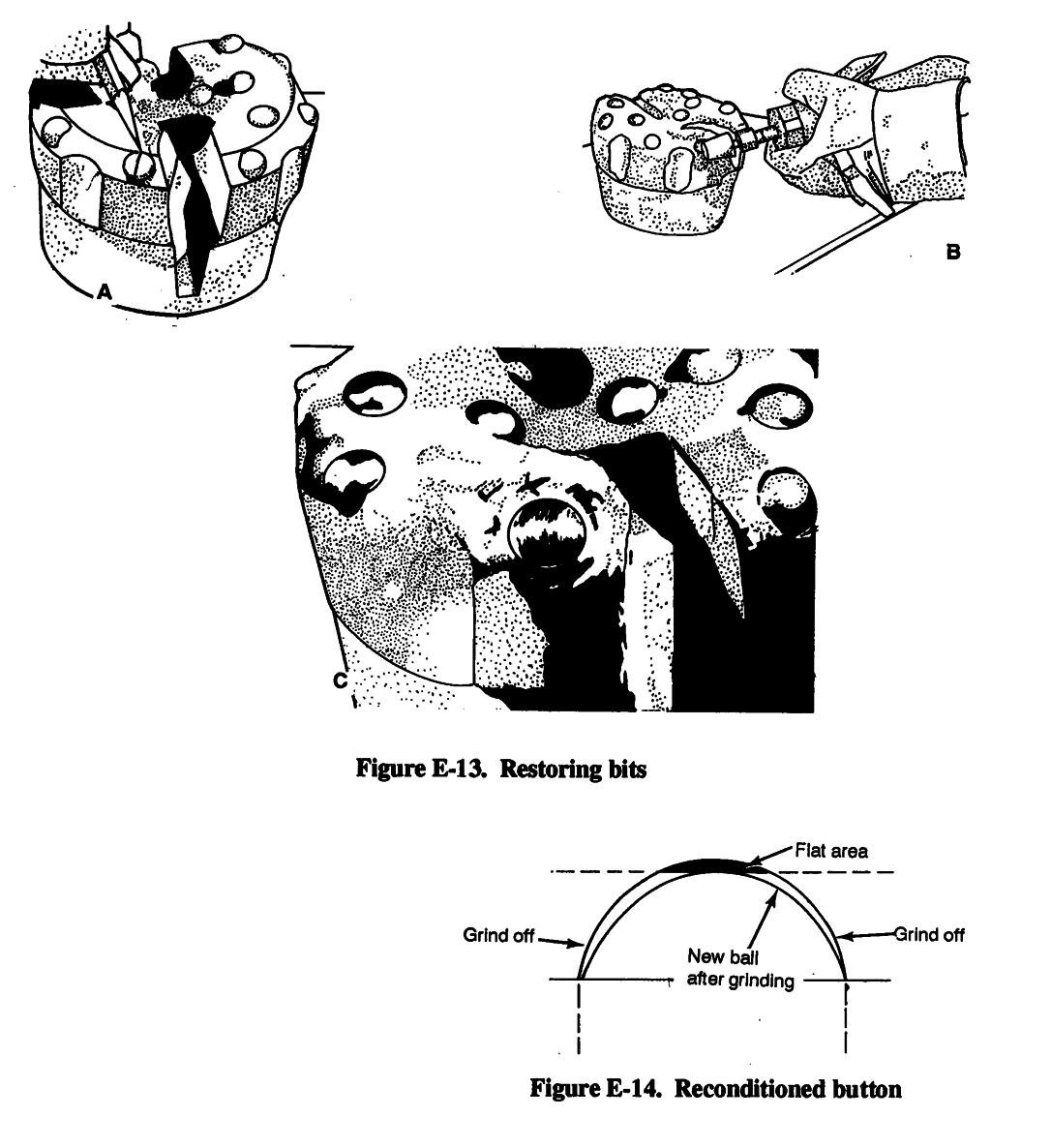

You must restore the original shape of the button when regrinding. To come close to this shape,

draw a pencil line down the center of the flat on the gauge button (Figure E- 13, A). Using the line

as a guide, grind the button on both sides, but leave the pencil line untouched (Figure E-13, B).

Leaving the pencil line ensures that the reground bit carbide will be concentric to the bit shank.

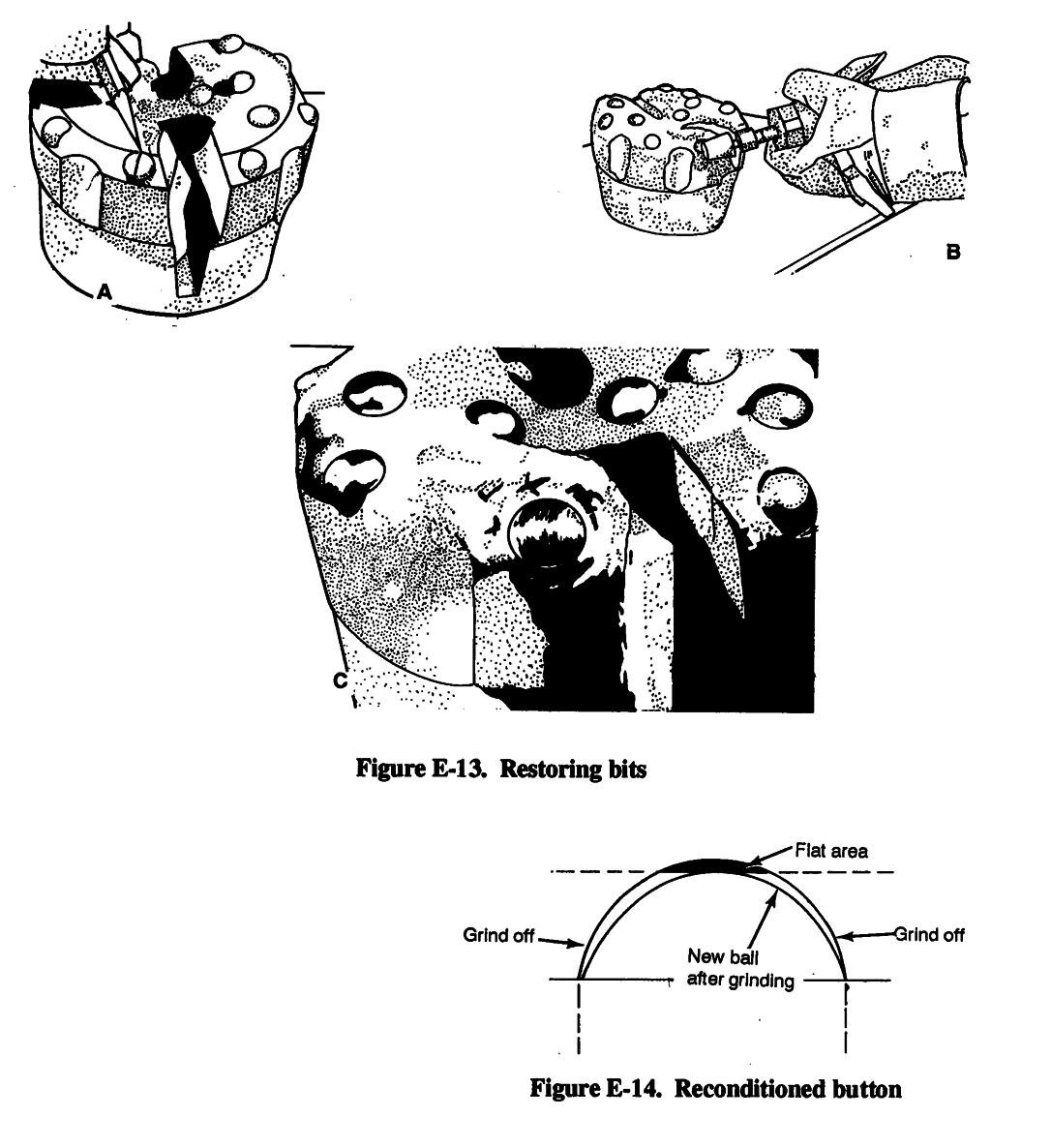

(When concentric, the carbides carry an equal share of the load.) Also, leaving the pencil line prevents you from grinding away too much carbide, thus extending bit life. Finally, blend the untouched line area (Figure E-13, C). When finished, the button should look almost new. Figure

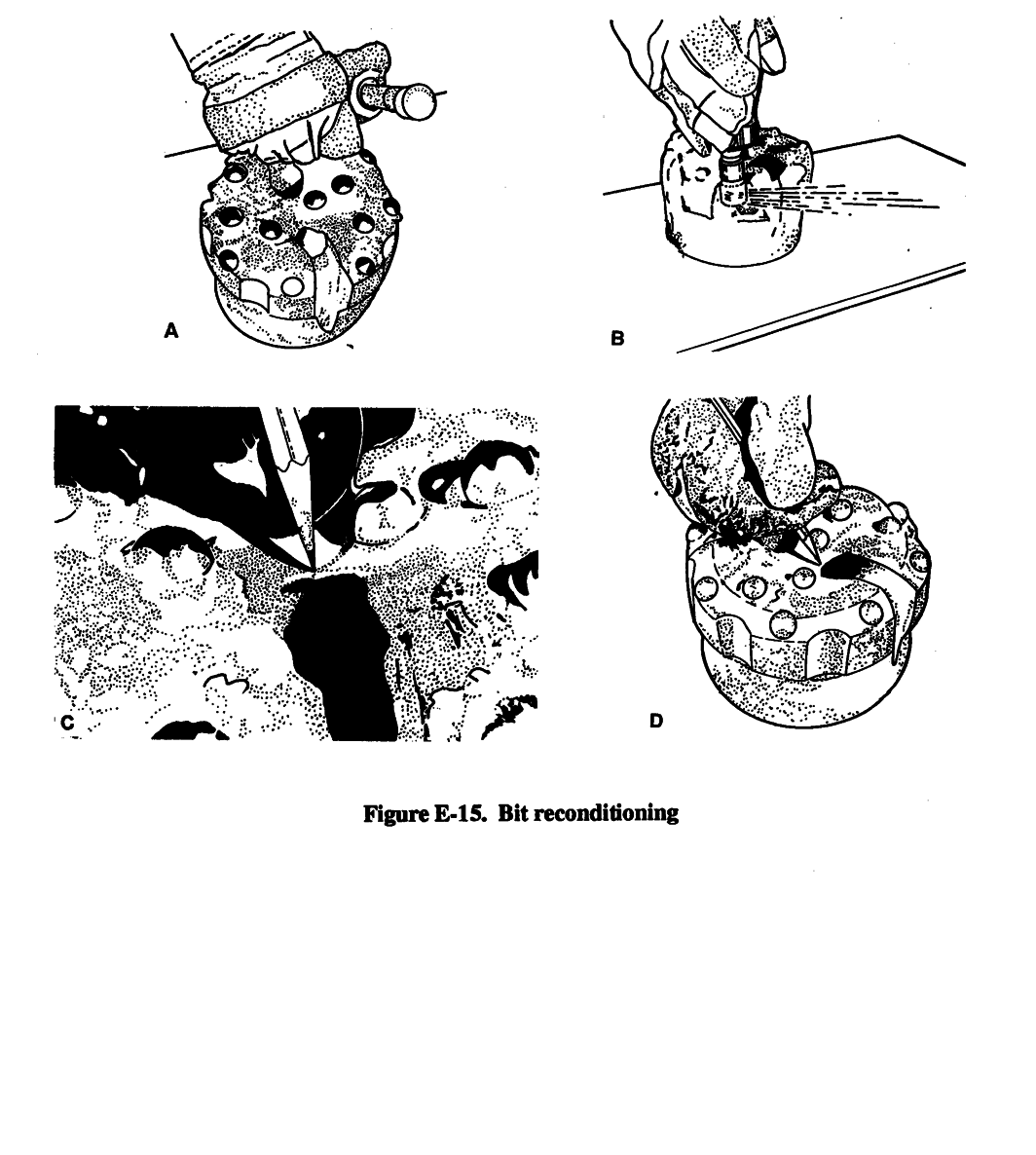

E-14 is a diagram of a reconditioned button. Although gauge buttons receive most of the wear,

grind all of the buttons, if necessary, (Figure E-15, A, page E-8); grind the flutes (Figure E-15, B);

check the blowholes (Figure E-15, C) and grind them back into shape (Figure E-15, D).

E-4. Rule of Thumb. In down-hole and drifter drilling, the most important factor contributing to poor performance and premature bit failure is operating the bit beyond the reconditioning point. A fixed guide outlining exact bit reconditioning intervals would be ideal. However, changing drilling E-6

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

conditions make the establishment of such a guide unrealistic. Therefore, establishing such intervals will ultimately be determined on the job. Consider the following recommendations: In hard abrasive rock recondition at the first sign of a flat on the button bit. A flat width should never exceed 1/4 inch.

In soft or less hard abrasive formations, recondition before reaching 10 percent of the expected life of the bit. This prevents alligator-type failures and ensures proper bit life.

E-7

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

E-8

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

Glossary

ACE Assistant Chief of Engineers

aquifer Saturated rock or soil unit, such as gravel,

AF Air Force

sand, sandstone, limestone, and fractured

igneous and metamorphic rock, that has

AFI Air Force instruction

sufficient hydraulic conductivity to supply water

for a well or spring.

AFP Air Force pamphlet

aquitard A unit that retards or slows the passage

AFSC Air Force Specialty Code

of water.

air-foam-gel technique Adding foamer to a fluid

AR Army regulation

in the same proportions as clear water to get a

richer, more stable foam.

Ark Arkansas

air-lift method A pump-testing method that uses

ARTEP Army Training and Evaluation Program

an air-lift pump,

attapuigite Commercially processed clay used for

air-line method A procedure to measure the

drilling in brackish or salty water.

water level using an air line; the air line is

ATTN

copper tubing or galvanized pipe that is long

attention

enough to extend below the lowest water level

augered well A well that is bored using hand-or

being measured.

power-driven earth augers.

air rotary driling A well-drilling method that

AWWA American Water Works Association

uses compressed air as the circulating fluid.

alligatoring A network of fine cracks and small

carbide flecks on a bit that appear after hours of

backwashing Well-development method. See

drilling in nonabrasive soft rock.

also jetting method; gravity-outflow

method; pressure-pumping method;

alluvium Soils that are deposited by running

pump-surge method; surge-block method

water.

ball-down method Installing screen using a

alt attitude

special end fitting,

ant-mound-like openings. See qanat

bail-down placement A method of

simultaneously placing the gravel pack and

AO area of operations

installing the screen.

APOD aerial port of debarkation

Barafos A white, granular sodium tetraphosphate

APOE aerial port of embarkation

thinner and dispersant added to drilling fluid to

prevent mud from sticking to sand grains.

aquagel Commercial chemical agent added to

mud drilling fluid to prevent it from freezing.

barite Commercial chemical agent added to mud

See also barite; fibratex; gel-flake;

drilling fluid to prevent it from freezing. See

impermex; micatex; smentex

also aquagel; fibratex; gel-flake; impermex;

micatex; smentex

aquiclude Subsurface rock or soil unit, such as

clay, shale, and unfractured igneous and

barreling A wear pattern that causes the diameter

metamorphic rock, that does not transmit water

of the bit body to exceed the gauge diameter of

readily and cannot be used as a water-supply

the buttons.

source.

basalt An igneous rock that is a very productive

water bearer.

Glossary-1

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

bentonite Commercially processed clay used for

cc cubic centimeter(s)

drilling; bentonite forms naturally from

decomposition of volcanic ash, consists of

centrifugal pump A variable displacement pump

aggregates of flat platelets, and contains sodium

in which water flows by the centrifugal force

montmorillonite, which is important in building

transmitted to the pump in designed channels of

viscosity.

a rotating impeller.

body metal A type of bit failure.

cfm cubic foot (feet) per minute

body wash Eroded body metal in bits.

cfs cubic foot (feet) per second

BOM bill of materials

circular-orifice meter A device used to measure

discharge rates.

boundary indicators Characteristics that are

indicative of local or regional groundwater flow

circular-orifice method A procedure to measure

systems.

discharge rates using a circular-orifice meter.

brass-jacket-type drive point Consists of a

closed-well method A compressed-air method

perforated pipe wrapped with wire mesh and

that involves using compressed air to close the

covered with a perforated brass sheet.

top of the well with a cap and by arranging the

equipment so air pressure can buiId up inside

brass-tube-type drive point Consists of a brass

the casing to force water out through the screen

tube slipped over perforated steel pipe for a

openings.

rugged construction.

cm cubic meter(s)

compressed-air methods Rapid, effective well-

cable jack A four-pronged receptacle located in

development methods. See also closed-well

the upper right comer of the panel on the

method; open-well method

electrical logging system.

CON DET A wetting agent added to drilling fluid

cable-tool method A very slow drilling method

to increase the dispersion action of

that can be used to penetrate rocky soil or

polyphosphates.

moderately hard sedimentary rock; the drill used

in this method does not require large amounts of

confined aquifer An aquifer that is completely

drilling fluid.

filled with water and is overlaid by a confining

bed.

CAL calibrate

confining bed Aquiclude that exists between

CAL ADJUST (calibration adjustment)

aquifers, water moves only within the aquifer.

Located in the lower right-hand comer of the

panel on the electrical logging system and used

consolidated deposit Rock that consists of

to zero the galvanometers when calibrating the

mineral particles of different sizes and shapes.

instrument.

continuous permafrost A zone where permafrost

carbide shear The most prevalent type of carbide

will be thick with no unfrozen ground. See also

breakage in bits

discontinuous permafrost; permafrost

casing ring and slip A device used to suspend the

continuous-slot drive point A screen with

casing at the ground surface and for pulling pipe

horizontal openings and one-piece welded

from the hole using jacks under each side of the

construction and contains no internal perforated

casing ring.

pipe to restrict the intake area.

catchment Formation whine impervious rock

CONUS continental United States

underlies a zone of fractured rock or alluvium

core barrel A double-tube sampler used to collect

that serves as a reservoir for infiltrated water; a

undisturbed soil samples in material that either

catchment can be a special type of aquifer.

contains gravel or is too hard for a thin-wall

cathodic protection. See sacrificial anode sample.

CB construction battalion

CPM critical-path method

Glossary-2

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

crop irrigation Surface indicator that shows the

double-casing placement A method of placing

use of surface water or groundwater for

gravel using a temporary outer casing.

agriculture.

drainage basin An area drained by a stream or

CSS combat service support

river. See also hydrographic basin (local

CUR (current) A red plug receptacle used to

drainage basin); major river basin; regional

connect the surface-current ground wire to the

river basin

instrument.

drawdown Measure of how much the water level

current switch The ON-OFF switch located

near the well is lowered when the well is

directly below the function switch; the current

pumped.

switch is a momentary spring-return toggle

draw works Main drill-head hoists that are

switch.

mechanically or hydraulically driven wire-line

winches,

d depth

drilling blind A condition that exists when a

driller continues to drill when fluid circulation is

DA Departmnt of the Army

lost,

Darcy’s Law Principle that describes the flow of

drive clamp Uused in driving easing or pipe and is

groundwater.

attached to the square of the drill stem.

DC direct current

drive head Device that is placed on the pipe to

protect the threads the the driving blows of the

Denisen sampler, See core barrel

drive clamps; a drive head is put on by

DD Department of Defense

unscrewing the bit, slipping the drive head over

the drilling stem, and making up the joint again.

DHD down-hole drilling

drive monkey A weight that slides over the pipe

discharge Water that moves from one area into

and is used in the falling-weight method of

another.

driving a well.

discontinuous permafrost A zone where

driven method Installing casing as with the

permafrost will be thin and maybe absent on

borehole, the cable-tool, or driven-point well

the south slopes of hills, in valley bottoms

method.

containing permeable alluvial material, and

under surfaces that have been cleared of

drive point Perforated pipe with a steel point at

vegetation. See also continuous permafrost;

the lower end to breakthrough pebbles or thin,

permafrost

hard layers.

dispersion treatment Adding dispersing agents to

drive shoe Device attached to the lower end of the

drilling fluid, backwashing, jetting water, or

pipe to prevent the pipe from crumpling while

water standing in the well to counteract the

being driven; a drive shoe is threaded to fit the

tendency of mud to stick to sand grains.

pipe or casing.

dissolution potential The possibility of

dump-bailer method Placing grout in a casing

developing high secondary permeability in a

using a dump-bailer machine.

soluble rock because the rock dissolves through

contact with groundwater.

EAC echelons above corps

DMA Defense Mapping Agency

electric-line method A procedure to measure the

DOD Department of Defense

water level using an M-Scope. See also

dolomite A carbonate rock that dissolves when

M-Scope

carbon dioxide from the atmosphere and

electrode selector switch A five-position switch

groundwater mix to form carbonic acid.

located directly above the ohmmeter on the

electrical logging system.

Glossary-3

FM 5-484/NAVFAC P-1065/AFMAN 32-1072

elev elevation

foot piece A device at the end of an air pipe that

breaks the air into small streams so that the

elevator (casing) A device used to handle pipe;

bubbles formed will be as small as possible.

the elevator is clamped around the pipe directly

under the coupling. See also pin hook; sand

formation stabilizer Material placed on the

line

outside of the screen to help prevent

deterioration of the annular space; using

ENGR engineer

formation stabilizer is an alternative method to

evaporation Direct radiation from the sun that

using gravel-pack material.

causes liquid at the surface of a body of water to

fpm foot (feet) per minute

change from a liquid to a vapor.

ft foot (feet)

evaporite Sedimentary rock that is generally

capable of storing and transmitting groundwater

ft/min foot (feet) per minute

but teds to dissolve in the water

function switch A three-position selector switch

E-Z Mud A synthetic, inorganic polymer.

located directly beneath the galvanometers on the

electrical logging system.

F Fahrenheit

gal gallon(s)

fall-in Material that accumulates in the bottom of

the borehole after circulation stops,

galvanometers A zero-centered micrometer on the

electrical logging system.

falling weight Driving method that uses a steel

driving bar attached to a rope; the bar falls

gel-flake Commercial chemical agent added to

freely inside the pipe and strikes the base of the

mud drilling fluid to prevent it from freezing.

drive point.

See also