CHAPTER 5

HOT WATER HEATING SYSTEMS

Section I. GRAVITY SYSTEMS

5-1. General.

5-2. Equipment.

a. In gravity systems, water flow is produced by

a. Pressure gauge/thermometer. For this type

the temperature difference between hot water in the

system, a combination pressure gauge and ther-

supply risers and cooler water in the return risers.

mometer is used. Water temperature in the system

The velocity and rate of flow through the system

is indicated on the thermometer scale and the

piping is low, so pipe sizes must be relatively large.

system pressure on a standard gauge dial.

Gravity systems may have either an open or a

b. Radiator valve. Each radiator has a valve for

closed expansion tank.

closing off circulation through the radiator. To

b. Distribution supply mains may be located in

prevent freezing of water in a radiator that is closed

the basement with up-feed to the radiators and

off, a weep hole is provided to allow sufficient

risers (as shown in figure 5-1), or the supply mains

water to circulate at all times. Unlike ordinary

may be located in the attic with overhead down-

steam or water pressure valves, there is no seal in

feed supply risers and return mains located in the

these valves. There is a barrel-like section in which

basement. The return connections are piped into a

a disk or gate makes a half turn to close the water

gravity return main which pitches downward to the

passage.

return opening in the boiler. Because there are

c. Radiator air vent. Each radiator has a com-

supply and return pipes throughout the building, all

pression air valve for venting air from the system

radiators are connected in parallel. The water

and radiator. Radiators are tapped at the top-feed

temperature is practically the same in all radiators,

and bottom return at opposite ends. Air is also

except for slight temperature drops in supply mains

vented from radiators through supply piping up-

between the boiler and the end of the circuit. Water

risers to the high point in the system, from which

temperatures at ends of circuits are lower than the

air is vented through a connection made to the ex-

rest of the circuit and are dependent on length of

pansion tank.

run and heating load. The rate of heat emission is

d. Expansion tanks. All heating systems require

also slightly lower per foot of radiation at the ends

an expansion tank to accommodate expansion and

of the circuit due to the slight drop in water

contraction of water which occurs as its tempera-

temperature.

ture changes. Excess water is stored in the expan-

sion tank until the water temperature decreases and

it is returned to the system. Gravity systems are

defined by the type of expansion tank installed:

open tanks or closed tanks.

(1) Open tank system. In open tank systems, the

expansion tank is freely vented to atmosphere.

Normally, these systems are limited to operating

temperatures of less than 180F.

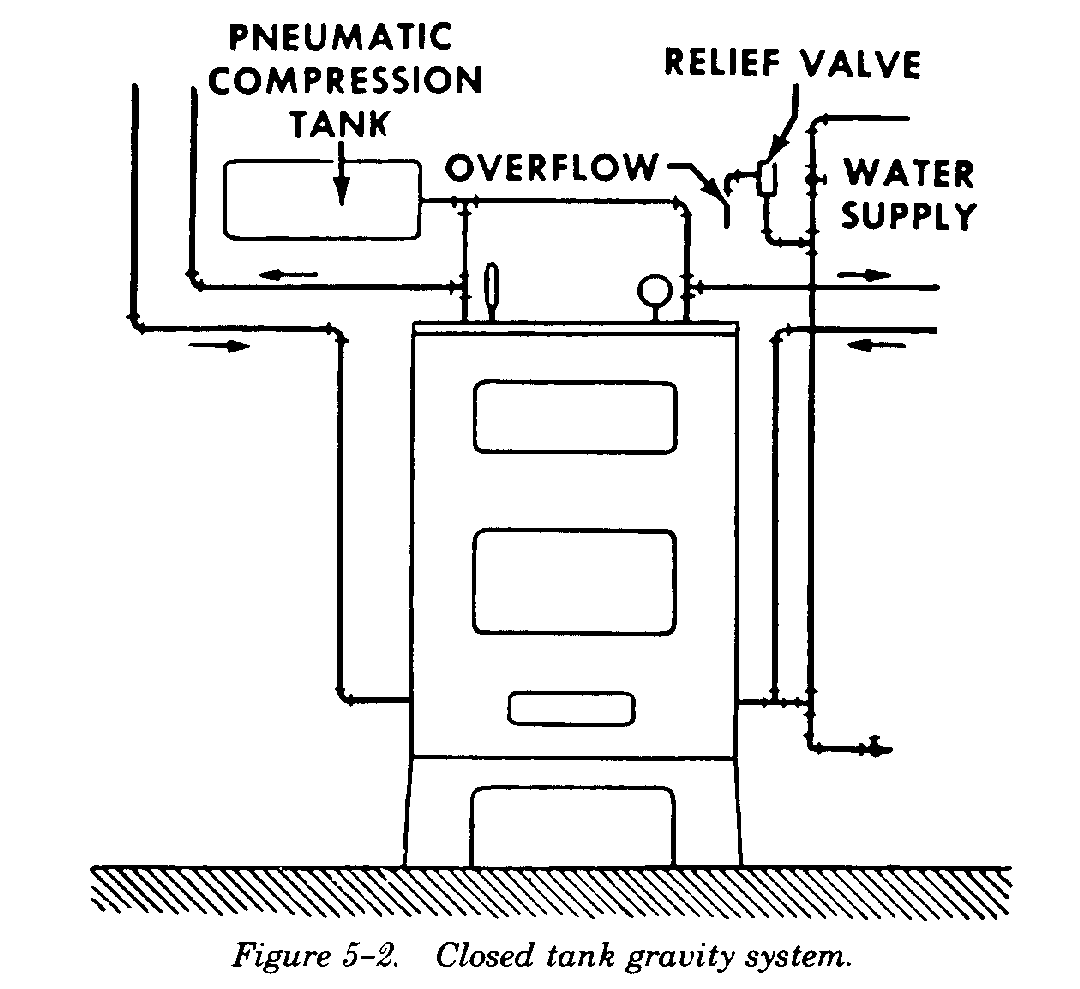

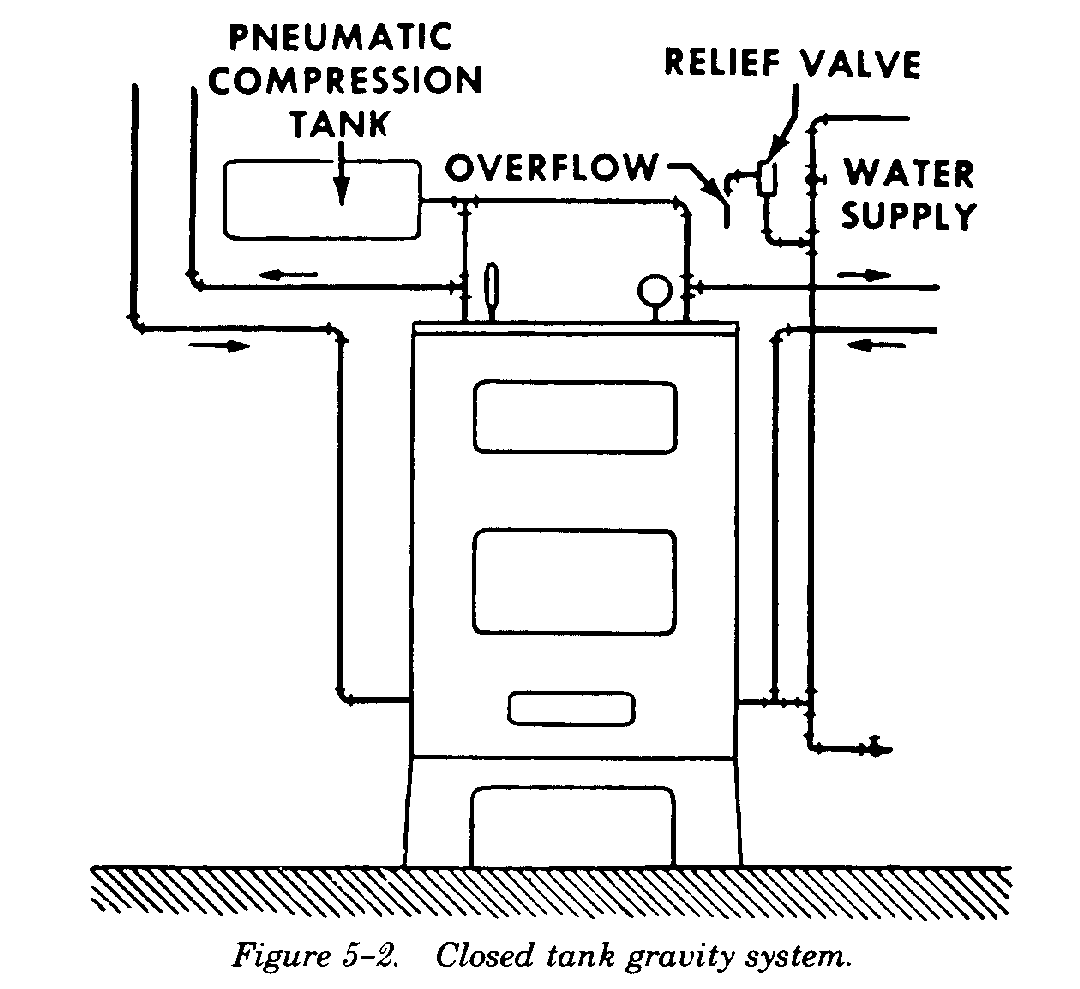

(2) Closed tank system. In closed tank systems

(figure 5-2), the expansion tank is airtight, sealed to

prevent free venting to atmosphere. As heated

water expands, the excess water moves into the

tank and compresses the entrapped air thereby in-

creasing the pressure on the system. When the

water temperature decreases, the water contracts,

air in the tank expands, the excess water returns to

the system, and the pressure drops. A closed ex-

pansion tank must be large enough to keep a res-

ervoir of compressed air above the water level to

cushion the excess water that enters. Thus the tank

must provide space for changes in both water and

air volume. A small tank with insufficient air can

5-1

TM 5-642

cause two undesirable conditions to occur. As the

occurs. It may be found necessary to add water to

temperature increases, the water expands and the

the system to enable venting of all radiators as the

system pressure may increase above the permissible

procedure progresses. A new system should be

level. This can cause the relief valve to open and

drained and refilled several times before starting the

waste water. As the temperature drops, the water

fire to remove grease, core sand, and other foreign

contracts and the pressure may drop below the

material. In the initial firing of a newly filled system,

permissible minimum. Air will not vent from the

it is advantageous to bring the system up to

system and additional air may be drawn in if the

temperatures considerably in excess of anticipated

high points of the system have automatic air vent

operating temperatures. This will tend to expel

valves.

entrained air from the system water and thoroughly

vent the system at start which will eliminate future

difficulties due to air pockets. After a new system

is in operation for a short period, open boiler

drains, since heavy core sand and similar materials

have a tendency to flow to this low part of the

system. When opening drains and feeding make-up

water to a hot water heating system in operation, be

careful that flow is not too fast. Otherwise,

excessive stress will be set up in the boiler structure

due to excessive temperature changes. After the

system has been fired approximately 10 days, open

air vents again and release air from radiators. Check

the system periodically for venting requirements.

5-4. Water level.

Probably the most important consideration in op-

erating a hot water system is maintaining the proper

water level in the expansion tank. Frequent

observation of the water level should be made. The

water level should be low enough in a cold system

to allow ample space for heated water to expand.

e. Boiler drain and cleanout openings. The low

point in the system has a boiler drain valve and the

5-5. Inspection and maintenance.

boiler is provided with rod-out openings so all

Operating difficulties of gravity systems are negli-

sediment, rust, and the like can be flushed out

gible, and corrective measures are seldom required.

readily.

Air which may accumulate in radiators should be

vented periodically to assure consistent heating

5-3. Startup.

system performance. If rapid fluctuation or

Close all vents, open all radiator valves, and open

pulsation of pressures should occur, check for

the water supply valve allowing water to flow until

system leaks, stoppages and relief valve operation.

the expansion tank is approximately half filled or

When a system is to be removed from service, drain

until water runs out of the overflow connection.

the system completely to remove accumulated

Beginning with the lowest radiators, open vent

sediment, rust, etc., and refill with clean water.

valves to remove air. Hold a small pail at each vent

and close the vent valve when free flow of water

Section II. FORCED CIRCULATION SYSTEMS

5-6. General.

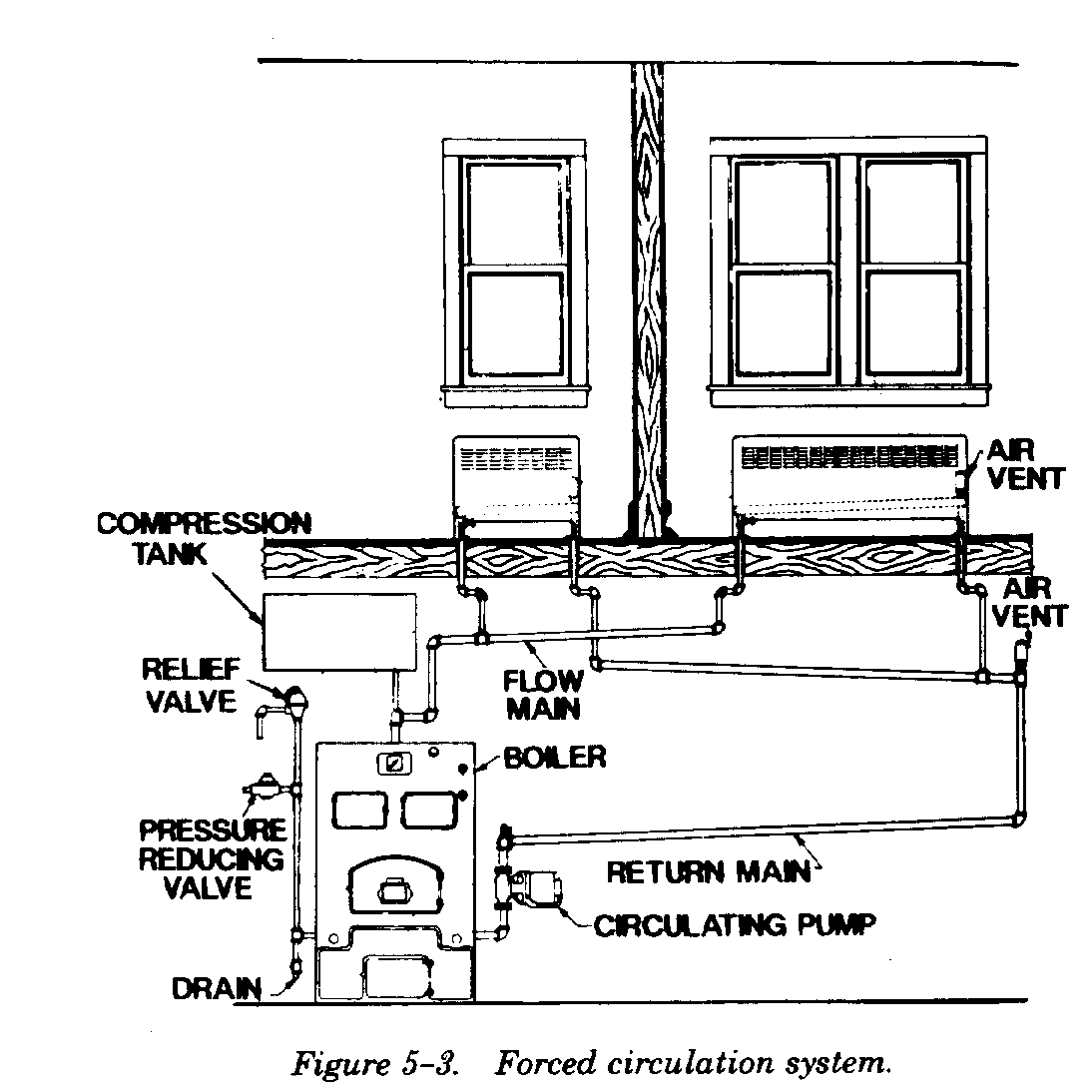

differs from the gravity flow type only in that a

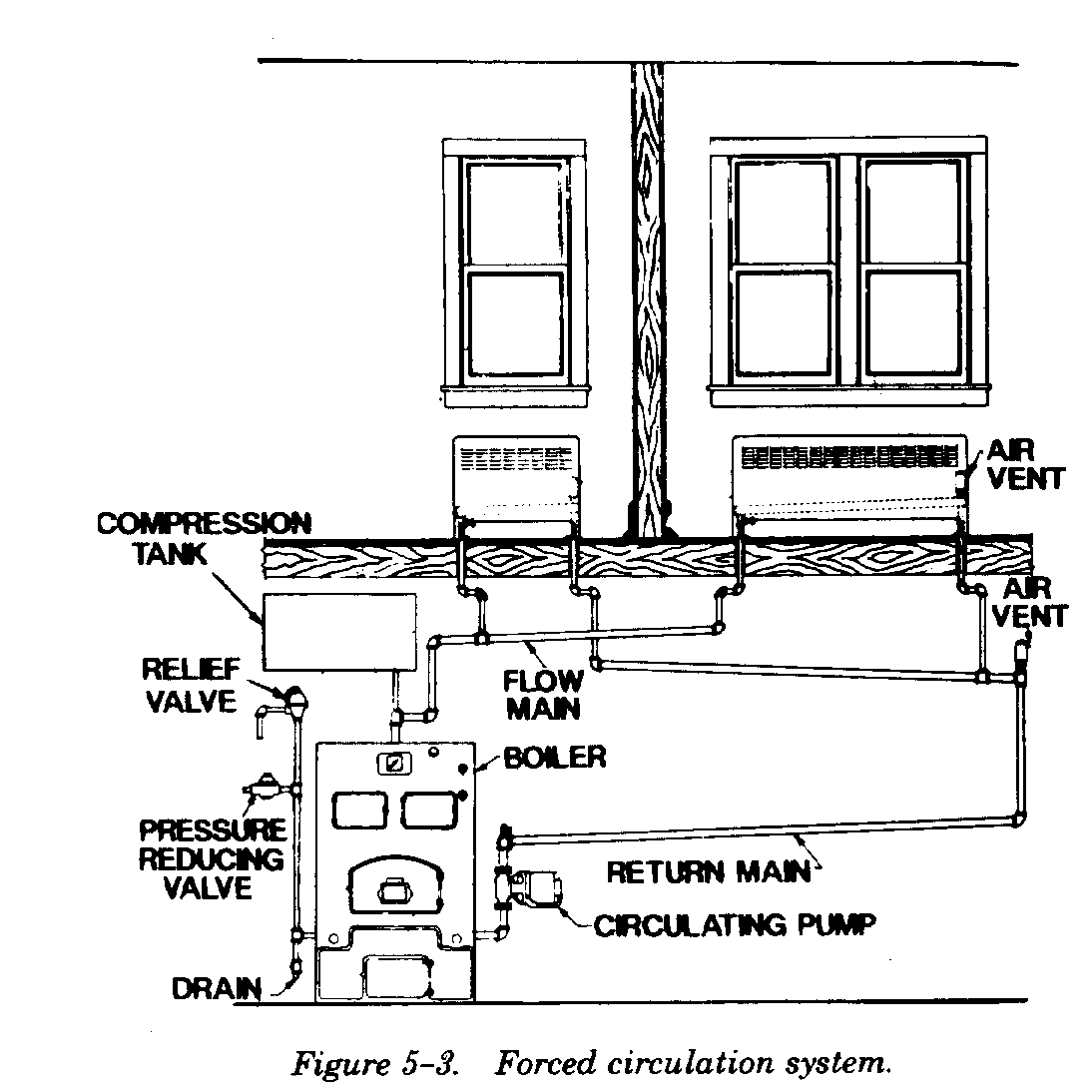

a. Forced circulation system piping and equip-

pump is installed at the termination of the

ment (figure 5-3) is similar to that of gravity flow

return piping near the boiler. Advantages of using

systems, except that pipe and equipment sizes are

a pump to produce the circulation are that much

generally smaller due to increased flow velocities.

smaller pipes are required and positive circulation

The general arrangement of the forced flow system

is assured throughout the system.

5-2

TM 5-642

thermometers are placed in the return or pro visions

are made for inserting immersion type test

thermometers near the pump. Circulation pump

rotation should be checked to make certain that

rotation is in the proper direction. Location of the

pump in the return line is suitable for small systems

where pump head is low, as in most residential

systems. Larger systems require the pump on the

supply side of the boiler, with the expansion tank

connected to the pump inlet.

b. Expansion tanks. Forced circulation hot water

systems almost always employ closed expansion

tanks. Since a closed expansion tank is sealed

against free venting to the atmosphere, the tank

may be above the highest radiator or heat trans-

mitter, or may be below the lowest one. The mini-

mum volume of a closed expansion tank is such that

expansion of water due to an increase in tem-

perature is cushioned against a reservoir of com-

pressed air above the water level in the tank. The

tank provides space not only for changes in water

volume, but also for variations in air volume within

the tank due to changes in air pressure. If the

b. There are some essential differences in circu-

closed expansion tank is below the radiators, the

lation in a forced circulation system as compared

tank is larger than if it is above them. The higher

with a gravity system. It is necessary to understand

the building the larger the air capacity should be

what takes place in order to remedy problems that

within the tank in excess of that required for

may be encountered in the field. The most

increase in water volume due to an increase in

important difference is that in the forced circulation

temperature. The closed expansion tank should be

system, the circulating force, neglecting gravity

located above the highest heat transfer surface in

effect, is produced locally by the pump. In the

tall buildings. A closed expansion tank located

gravity system, the circulating force is produced

above heat transfer surfaces of a hot water heating

uniformly throughout the system in the vertical runs

system should be connected by a direct pipe to the

of piping. A second difference is that the self-

flow main leaving the boiler in order to enable air to

regulating property of a gravity system is almost

migrate easily to the expansion tank. In a closed hot

lacking in the forced circulation system. Therefore,

water heating system, water tends to absorb air at

if pipe size and radiator connections in the forced

a rate which increases with an increase in pressure

circulation system are greatly restricted at some

and decreases with an increase in temperature.

points or improperly sized and balanced for uniform

Means should be provided to adjust and to observe

flow, the effect is likely to be serious.

the proportion of air within any closed expansion

tank. This includes provision of an air inlet valve, a

5-7. Equipment.

water gauge, and a relief valve. A source of

The principle equipment of a forced circulation

compressed air for renewing the air cushion is

system includes a boiler or heat exchanger, radia-

highly desirable, especially in large, high pressure

tors or fan-coil units, one or more circulating

hot water heating systems where it is inconvenient

pumps, an expansion tank, a relief valve, a hand or

and impractical to drain water in the system to

automatic fill valve to maintain set system pressure,

permit introduction of air.

and appropriate controls for pump operation and

c. Relief valves. All hot water heating systems

automatic firing equipment.

require proper provision for pressure relief. Equip-

a. Hot water pumps. Circulating or booster

ment can be subjected to excessive pressure by ex-

pumps are usually of the centrifugal type and are

pansion of confined water in the system if: connec-

installed in the pipe line with flanged fittings. In a

tions to expansion tanks are closed due to freezing

system that includes only one pump, each return

or other stoppage causes; the system*s expansion

line is connected to a common pump inlet header

tank becomes completely filled with water or; the

through a square-head cock to enable balancing of

air volume is inadequate to allow for necessary ex-

the system by equalizing return temperatures from

pansion. A conventional type hot water pressure

various circuits. In large installations immersion

relief valve which employs a spring-loaded dia-

5-3

TM 5-642

phragm to raise a valve seat when water pressure

standard hot water heating system equipment, and

exceeds 30 psig is installed in each system. This

the reducing valve setting should be kept as low as

valve is located in the cold water supply line be-

possible. The valve should be located at approxi-

tween the boiler and the reducing valve. The con-

mately the same level as the top of the boiler.

ventional reducing and relief valve installation does

not provide adequate protection for systems in

5-8. Piping systems.

which radiators are at boiler level as in a single

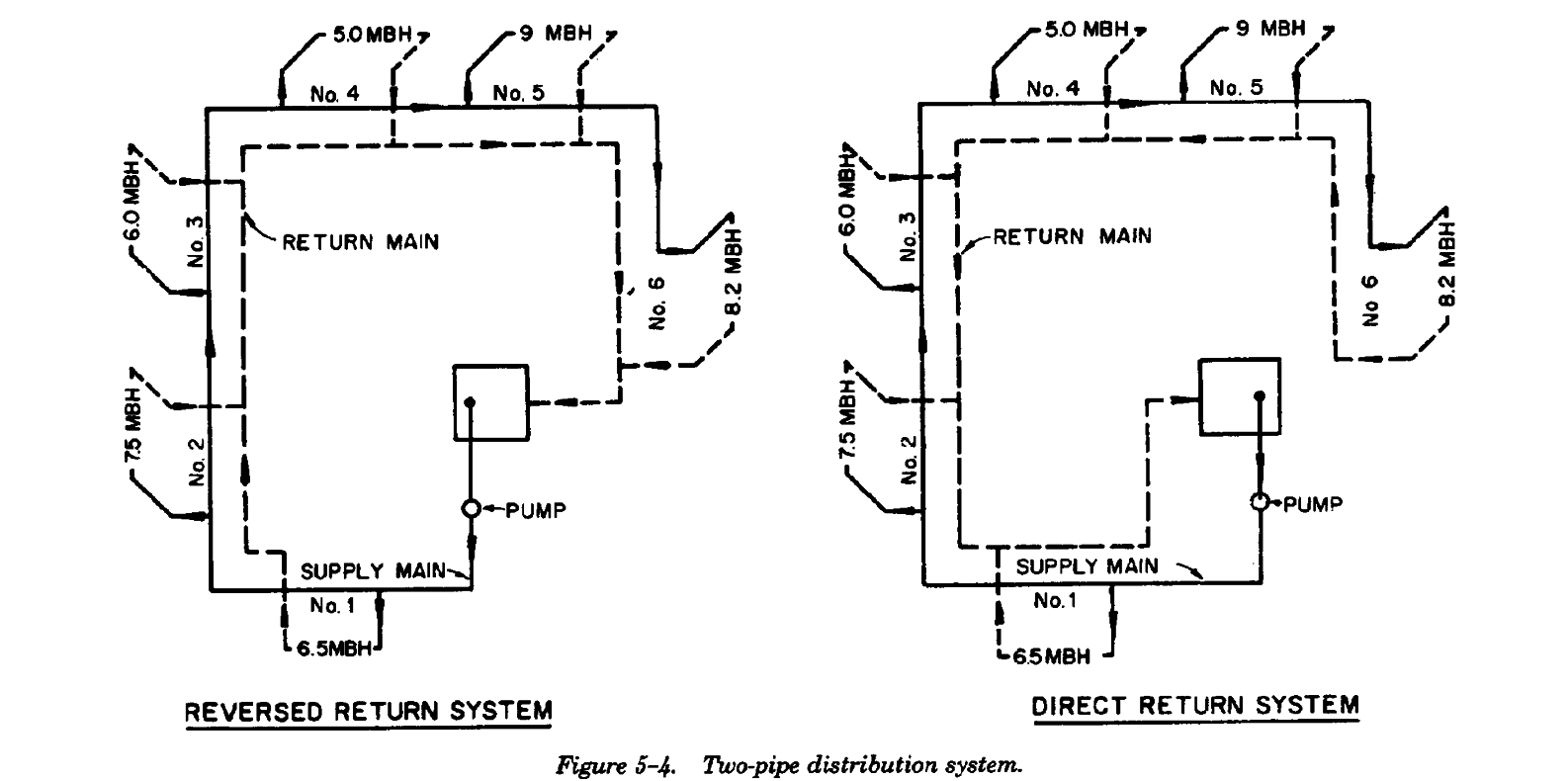

Forced circulation hot water heating systems gen-

story building without a basement where the boiler

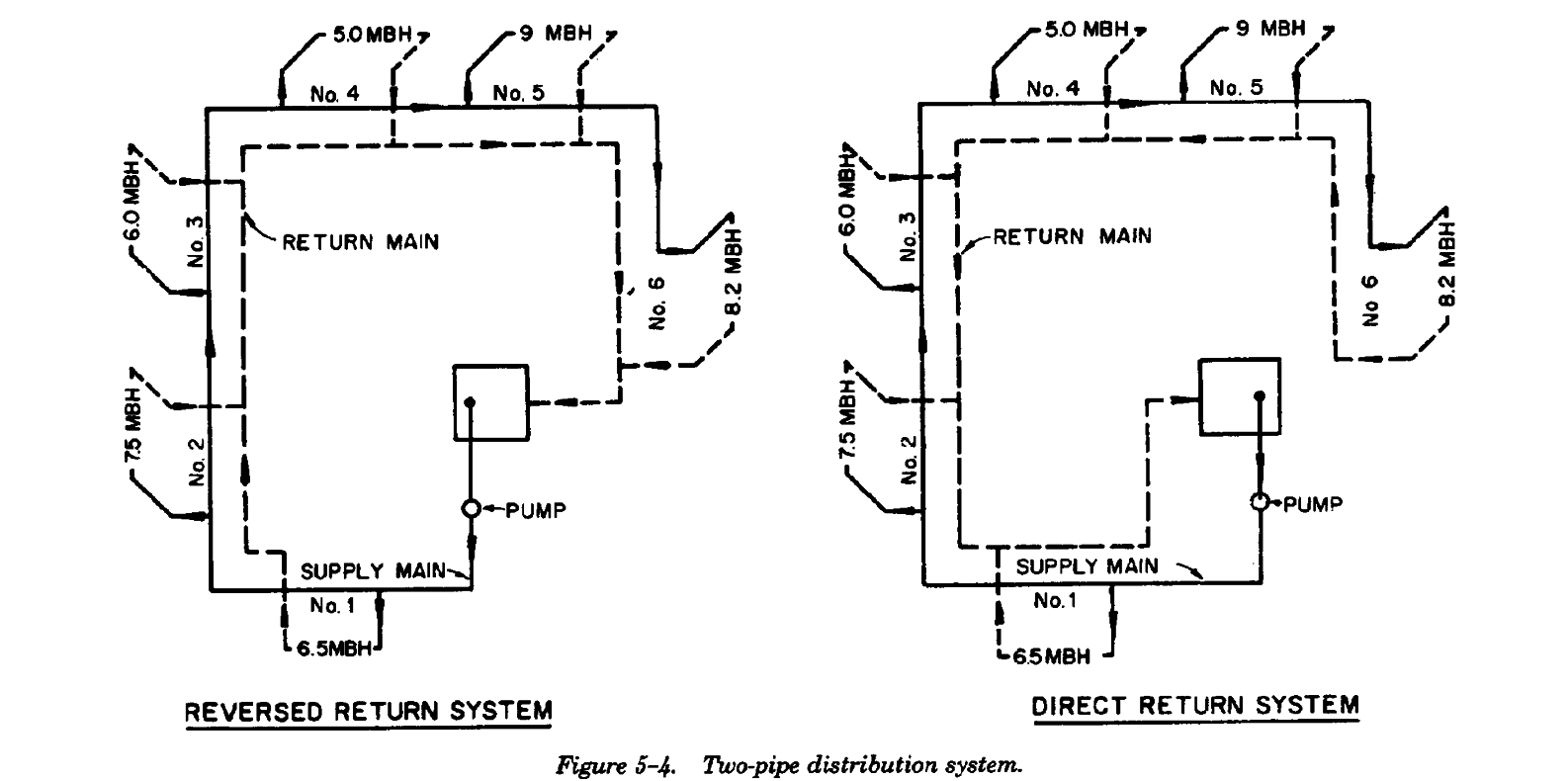

erally use two-pipe systems. The two-pipe system

is installed at grade level in a utility room or similar

has two mains: the supply main which feeds water

location. Where radiators are at boiler level, instead

to the risers that serve the heating units, and the

of the conventional make-up water connection, an

return main which collects the water returned from

automatic water line regulator is installed in the

those units. The two mains run side by side; the

vertical riser between the main boiler take off and

supply main decreases and the return main increases

overhead expansion tank. The relief valve is located

in size where the branches connect. Since the

in the vertical riser at the water line of the

heating units of a two-pipe system are connected in

regulator.

parallel, a minimum pumping head is required.

d. Reducing valves. A reducing valve in the

Also, if throttle valves or restricting orifices are

make-up or cold water line to the boiler automati-

used in the risers, the flow through individual units

cally keeps the closed system supplied with water

can be adjusted easily over a wide range. The two-

at the predetermined safe system pressure. The

pipe system, however, requires more pipe and

valves are usually factory set at 12 psig pressure,

fittings than the one-pipe system. Two pipe systems

which is equivalent to a static head of 27.6 feet of

may be classified as either direct-return or reverse-

water, suitable for buildings up to three stories

return depending on the direction of the return

high. The valves can be reset for higher pressures if

(figure 5-4).

desired. Thirty (30) psig is the maximum for

a. Direct return systems (figure 5-4.2). The

tional circuits, the flow circuits are hydraulically

heating units of the two-pipe, direct return system

unbalanced. This condition may cause the first unit

are in parallel. Water taken from the main to feed

to have a greater flow than is required to develop

the first unit is returned first; that removed for the

its full capacity, while, in a large system, flow

second unit is returned second; and so forth

through the last unit may be so small that

throughout the heating units. Since this procedure

practically no heat is delivered. Restricting orifices

causes a progressively greater friction loss in addi-

or throttle valves are sometimes used to correct

5-4

TM 5-642

flow distribution and to balance the system after it

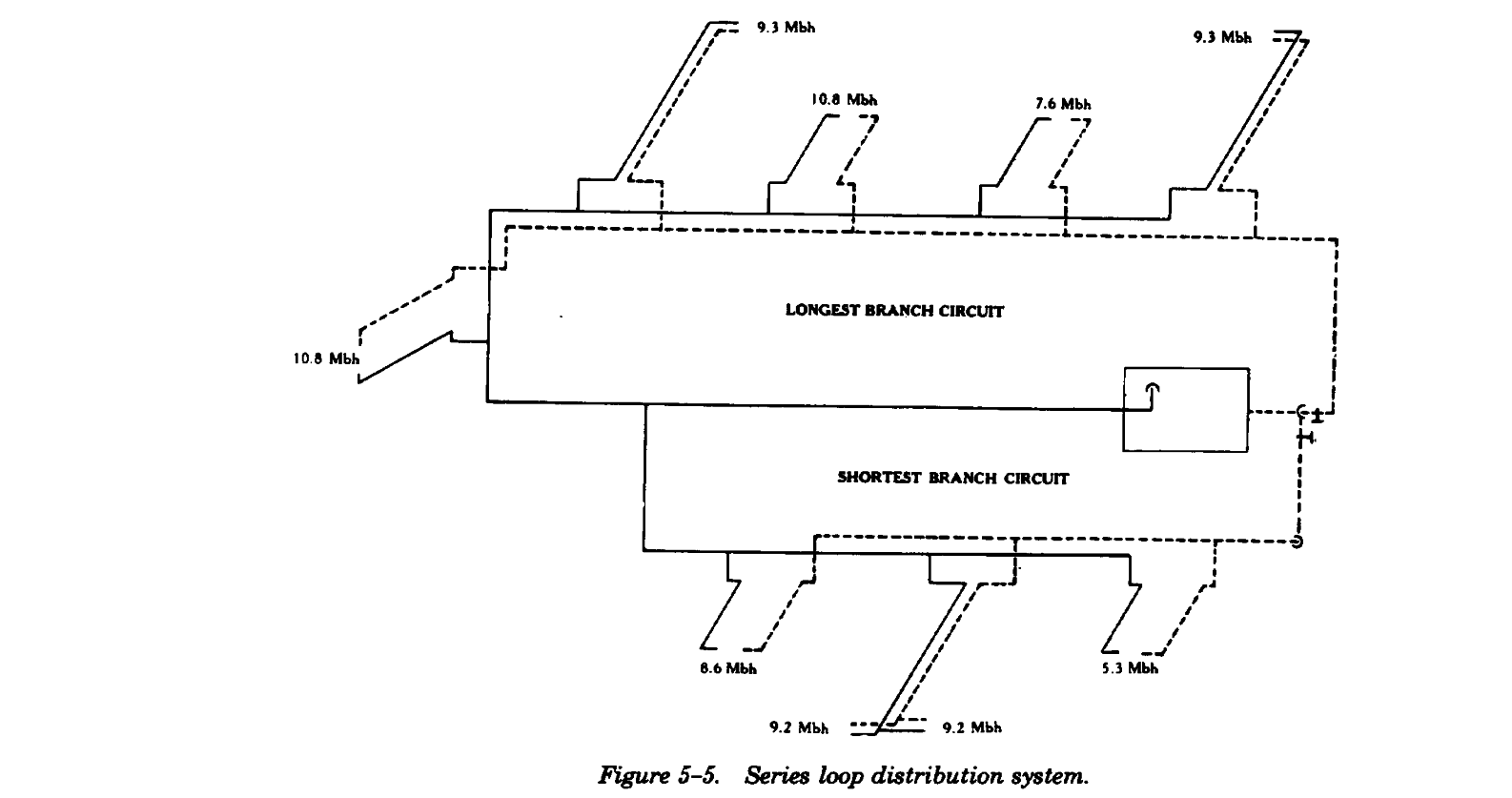

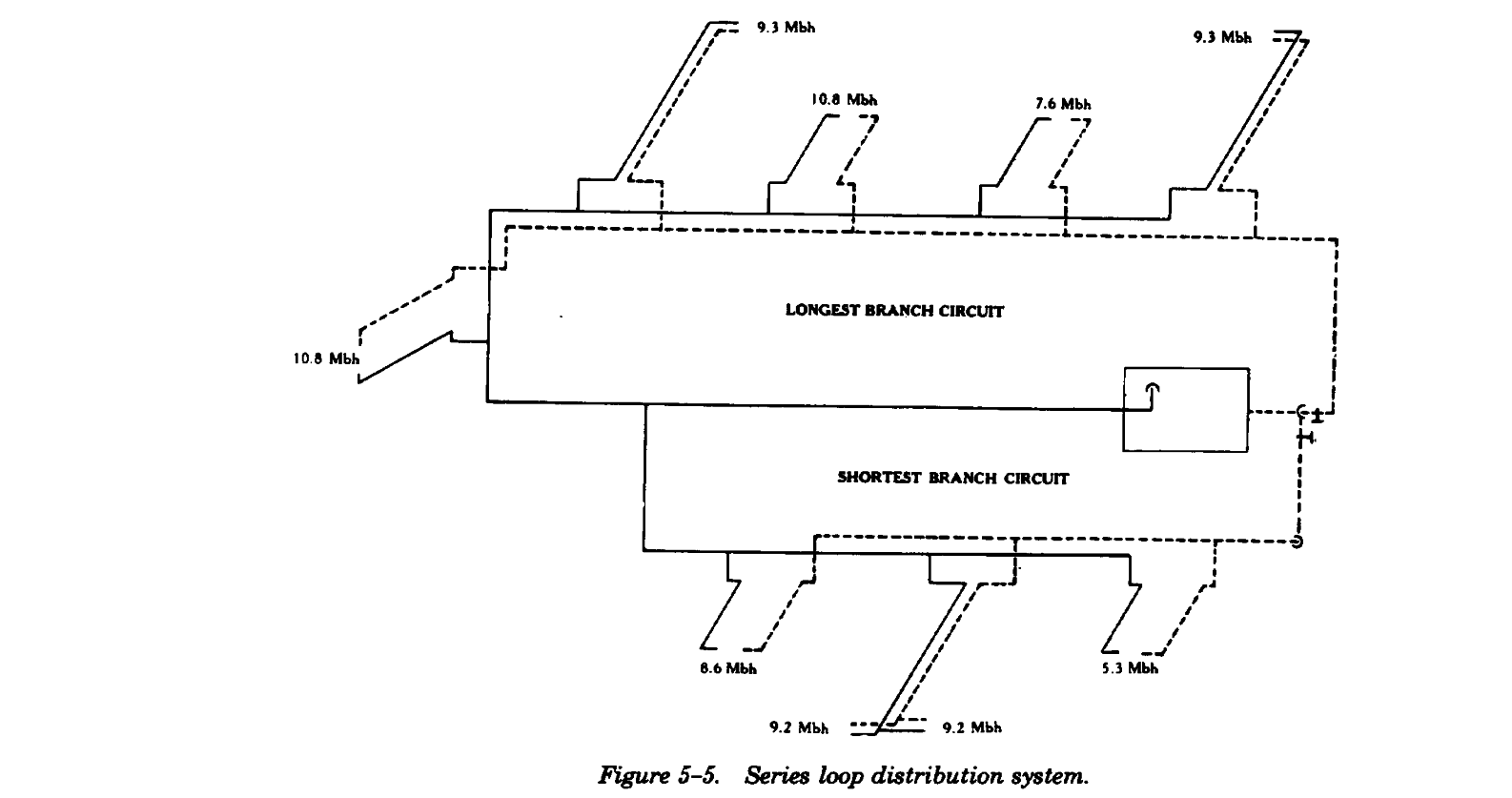

loop system may have one or more loops or

is placed in service.

circuits. All the heating units in a circuit are

b. Reversed return systems (figure 5-4.1). In the

installed in series and the same amount of water

two-pipe reversed-return system, water taken from

flows through each and through the connecting

the main to feed the first unit is returned last to the

main. For a given available head, the length of the

return main; the water supplied to the last unit is

circuit and the number and type of heating units de-

returned first. As a result, all unit circuits are

termine the water flow rate and temperature drop.

approximately equal in length, a condition

The water temperature decreases progressively as

conducive to system balance. The reversed return

the water flows through each successive heating

system may require more pipe than the direct

unit. Series systems are frequently used in connec-

return; however, its inherently better flow distri-

tion with baseboard radiation. Neither the flow nor

bution and natural balance without the aid of ad-

the temperature of the water supplied to individual

ditional valves or orifices, compensate for the addi-

heating units can be regulated in this system.

tional cost.

Delivery of heat, therefore, is usually controlled by

c. Series-loop systems (figure 5-5). A series-

air dampers in the baseboard radiation cabinets.

5-9. Inspection and maintenance.

capacity of the system and the size of the expansion

Generally, a good hot water heating system rarely

tank. Observe and record this characteristic when

presents operating difficulties if temperatures and

the system is in perfect operating condition. Any

pressures are kept within normal ranges. If rapid

later deviations from the established pressure may

fluctuation or pulsation pressures should occur,

indicate that the water level is low (if pressure

check for system leaks, stoppages, and relief valve

decreases) or that the system is stopped or plugged

operation. The indicated pressures of a closed

(if the pressure is above normal). When a system is

system may increase slightly with the increase of

to be removed from service, drain the system

water temperature. Each system has its own defi-

completely of accumulated sediment, rust, and the

nite increase characteristic, determined by the water

like, and refill with clean water.

5-5

TM 5-642

Section III. HOT WATER FAN-COIL UNITS

5-10.

General.

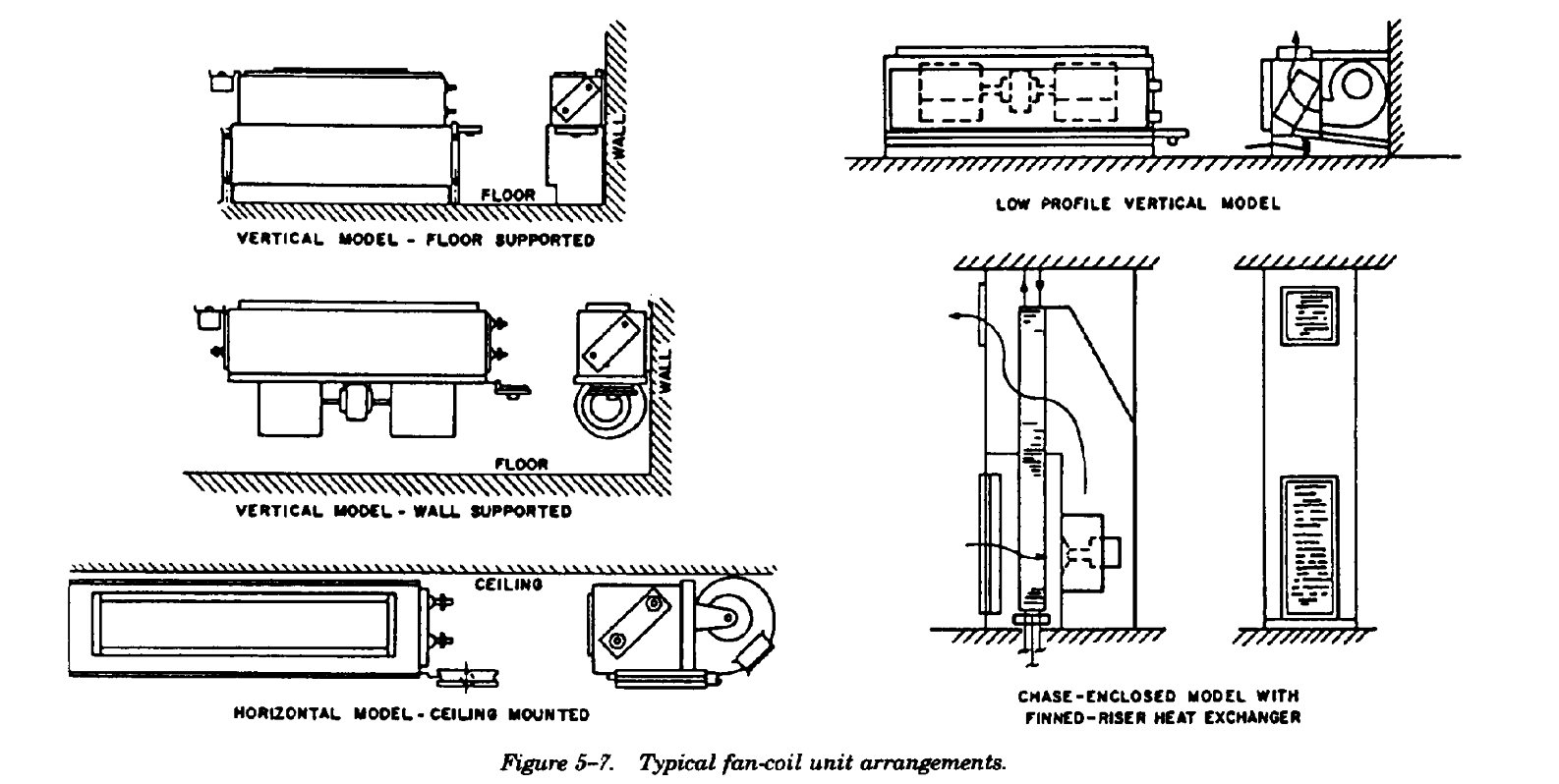

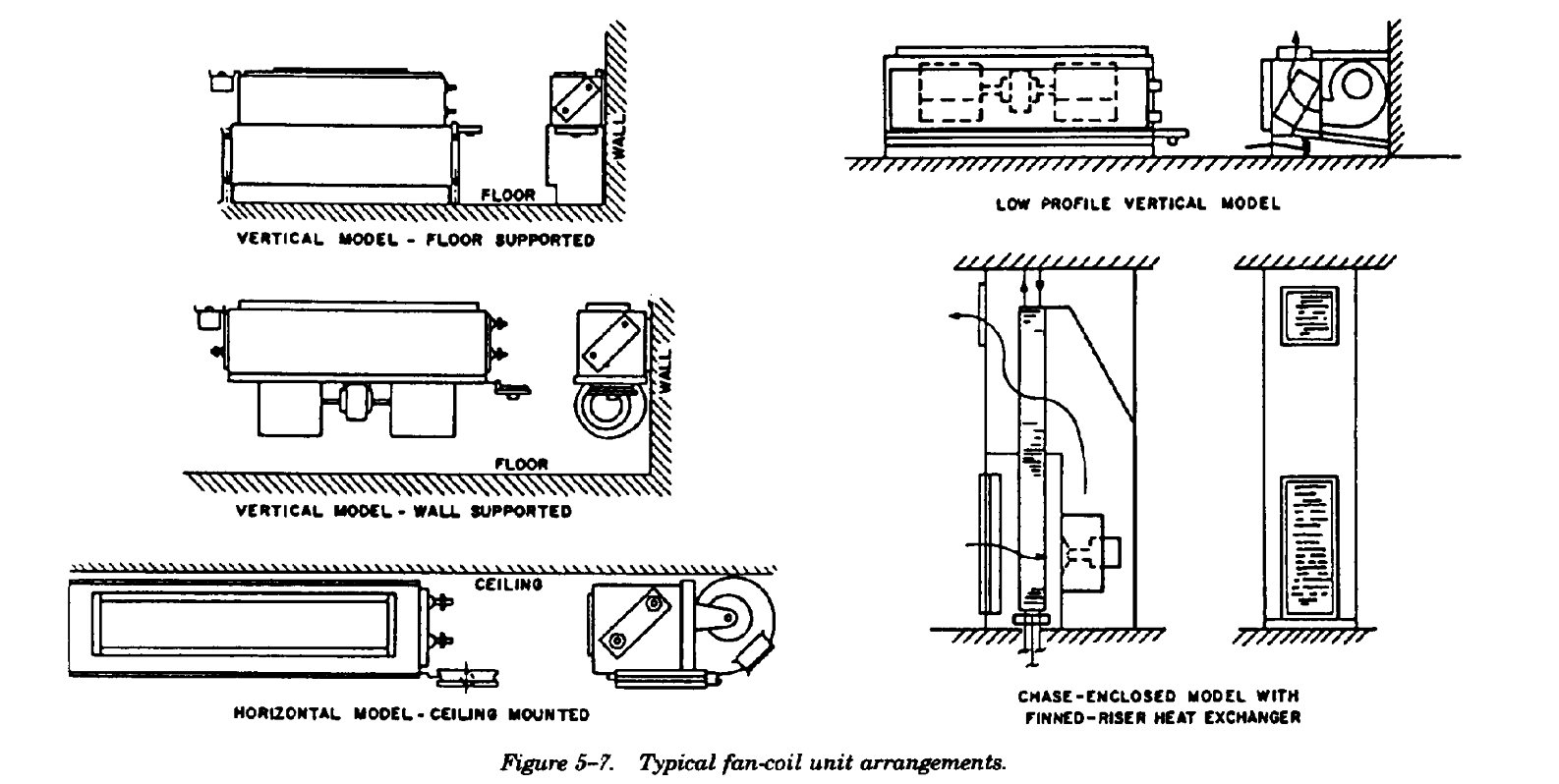

b. Room fan-coil units are available in a number

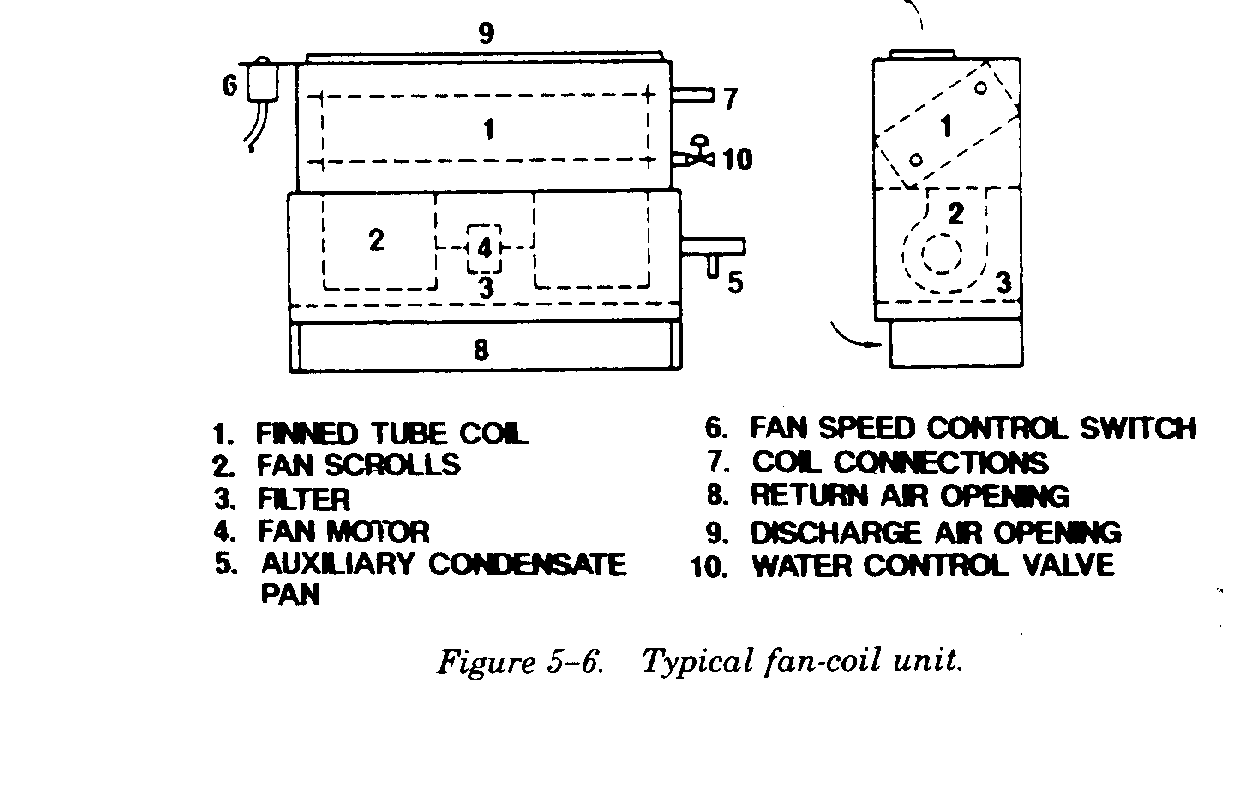

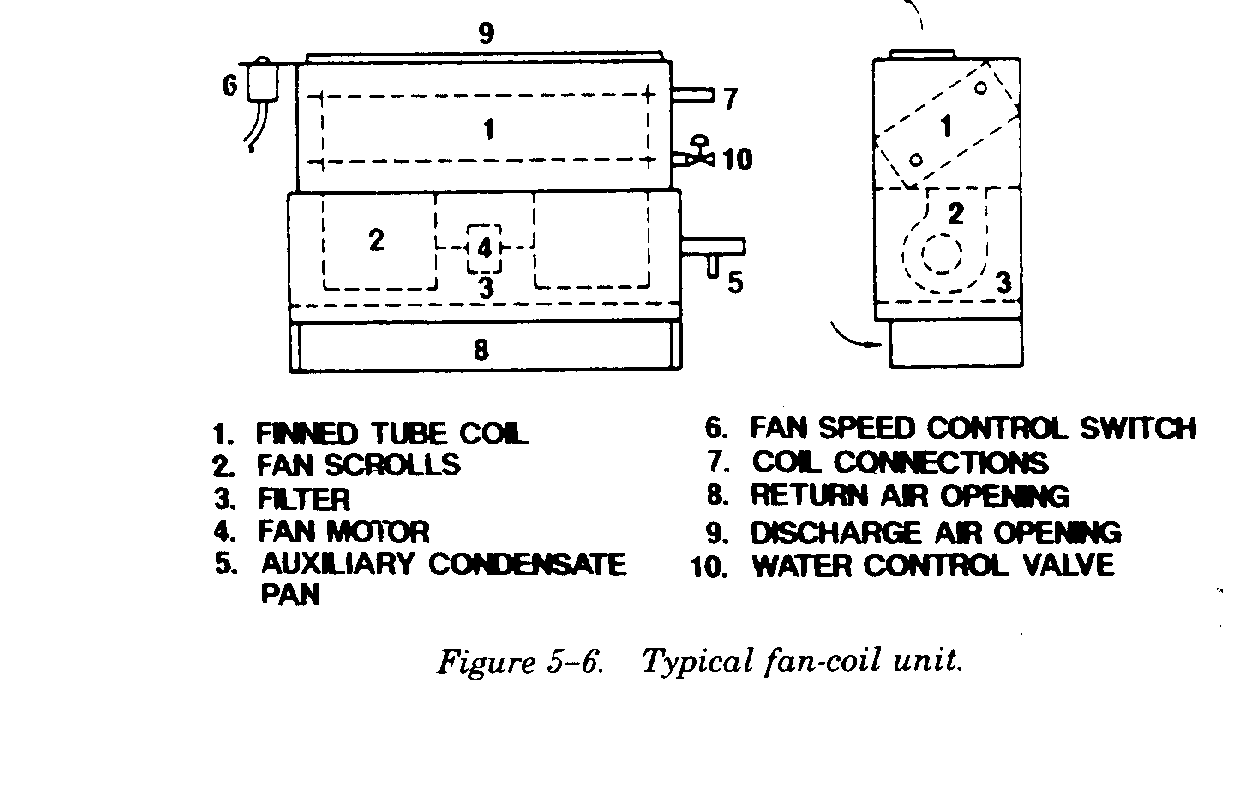

a. Basic elements of fan-coil units are a finned-

of physical configurations. Figure 5-7 show several

tube coil and a fan section (figure 5-6). The fan

arrangements of vertical wall mounted units and a

section recirculates air continuously from within the

horizontal ceiling mounted model. Low vertical

space through the coil which contains hot water.

units are available for use under windows with low

The unit may also contain chilled water or an

sills; however, in some cases the low silhouette is

electric resistance, steam, or hot water type of

achieved at a compromise of such features as filter

heating coil. A cleanable or replaceable low effi-

area, motor serviceability, and cabinet style.

ciency filter is located upstream of the fan. This

filter prevents the coil from becoming clogged with

dirt or lint entrained in the recirculated air. It also

protects the motor and fan, and reduces the level of

airborne contaminants within the conditioned space.

The unit is equipped with an insulated drain pan.

The fan and motor assembly is arranged for quick

removal to facilitate servicing. Ventilation air boxes

with a dampered opening for connection to

openings in the outside wall are optional.

5-6

TM 5-642

c. Floor-to-ceiling chase-enclosed units are

b. Water control valves should not be used

available in which the water and condensate drain

where aperture outdoor intakes are used, unless

risers are part of the factory furnished units. If the

there is a provision for freeze protection. Capacity

riser is located in the partition between two rooms,

control is achieved in certain configurations, by

both rooms can be served by the same unit. One

modulating a damper to bypass all or part of the air

style combines the water risers and coil into one

around the unit coil.

assembly by finning a portion of the water riser.

c. Fan speed control may be automatic or

Water flow is continuous through all units and air

manual. Automatic control is usually on-off with

bypass room temperature control is used. A

manual speeds selection. Some units are equipped

limitation of this style of unit is the size of the

with variable speed motors for modulated speed

finned riser; usually only 10 or 12 floors can be

control. Room thermostats are preferred where fan

stacked on a common riser. Another style of floor-

speed control is used. Return air thermostats will

to-ceiling unit overcomes this limitation by using a

not give a reliable index of room temperature when

separate coil which is sized independently of the

the fan is off.

risers.

d. If horizontal units are installed, air velocity

d. Horizontal overhead units may be fitted with

must be maintained to reach (throw) to the outside

ductwork on the discharge to supply several out-

wall area, and manual readjustment of fan speed

lets. A single unit may serve several rooms, e.g. in

may be undesirable.

an apartment house where individual room control

is not essential and a common air return is feasible.