easily; glasses no longer than 12 inches are

b. Keep gauge dials and glass covers clean and

preferable.

well lit to permit easy reading at any time.

c. Test and reset pressure gauges as required by

4-38.

Installing gauge glasses.

manufacturer*s instructions or when readings

a. Fuse cut ends since glasses are weakened by

appear abnormal.

broken surfaces.

d. Installation of suitable connections to each

b. Place glass connections in perfect alignment

boiler for inserting a test gauge is of great assist-

and free from strain on glasses. Jamming or twist-

ance. Install a tee connection on the gauge line so

ing glasses when tightening the stuffing box nuts

that a standard test gauge may be used to check the

causes breakage.

condition of an indicating gauge.

c. Gauge glasses are broken easily if scratched.

e. Never admit steam directly to the gauge. If

Exercise great care in storing.

steam is admitted to the gauge, the gauge should be

d. Gauge glasses should be protected from an

retested. Be sure the siphon is properly filled with

accidental blows. Provide rods or other means of

water at all times.

guarding the glass.

f.

Steam gauges on a battery of boilers should

e. Open and close all cocks slowly.

be graduated alike and should be of the same type.

f.

Wear goggles during this phase of installation.

Remove all broken pieces. Open valves slowly and

4-41.

Safety valves.

blow out any debris taking care to turn face away.

a. Never operate a boiler without one or more

Make sure new glass is of the proper length, that

safety valves of sufficient capacity as indicated by

the drain is open and connections are lined up.

the ASME Code. Keep those valves free and in

Insert glass, but do not set up too tight. Replace the

working order at all times.

guard if cocks must be opened and closed near the

b. Never place a stop valve between the boiler

position of the glass or cannot be operated from the

and a safety valve.

floor.

c. Test the safety valve periodically by lifting the

g. Open the top valve slightly and warm glass by

valve off of the seat by hand. This should not be

allowing a little steam to pass through so that heat

done unless the boiler pressure is from 80 to 85

is evenly distributed over the entire column. If

percent of the present popping point. Under no

water is admitted first, uneven heating may break

condition attempt to prevent safety valve leakage

the glass. When the water level appears steady,

by tightening the spring.

open the bottom valve wide and then open the top

d. When a safety valve does not pop at the re-

valve wide. Always test the water glass when

quired pressure, check carefully to determine the

replacement has been made. This should also be

cause. If the faulty valve condition cannot be cor-

done when the boiler is placed in service and when

rected, replace the valve.

difficulty is experienced with foaming or priming.

e. Set safety valves in accordance with ASME

Code requirements to pop at the proper pressure,

blow to reduced pressure, and close without chat-

4-33

TM 5-642

tering or simmer. All safety valves should be prop-

of leaky valves. Discharge ends of blowdowns

erly sealed after being set.

should be open for inspection at all times.

4-42.

Blow-down pipes.

4-43.

Dampers.

Maintain all valves, cocks, and lines carefully and

Inspect all dampers for looseness and other defects

inspect regularly for defects. Where leaks are dis-

before boiler is placed in service. Examine dampers

covered, make repairs as soon as practicable. Ex-

periodically and keep in good condition.

amine discharge end of blowoff pipes for indication

Section IX. TRAPS

4-44.

General.

The basic purpose of a trap is to discharge conden-

sate, entrained air, and other gases from a steam

area, while preventing or minimizing loss of steam.

Various types of traps in use are: bucket,

thermostatic, combination float and thermostatic,

and thermodynamic traps. For steam heating sys-

tems, the thermostatic, or combination float and

thermostatic (F&T) are most commonly used.

4-45.

Thermostatic traps.

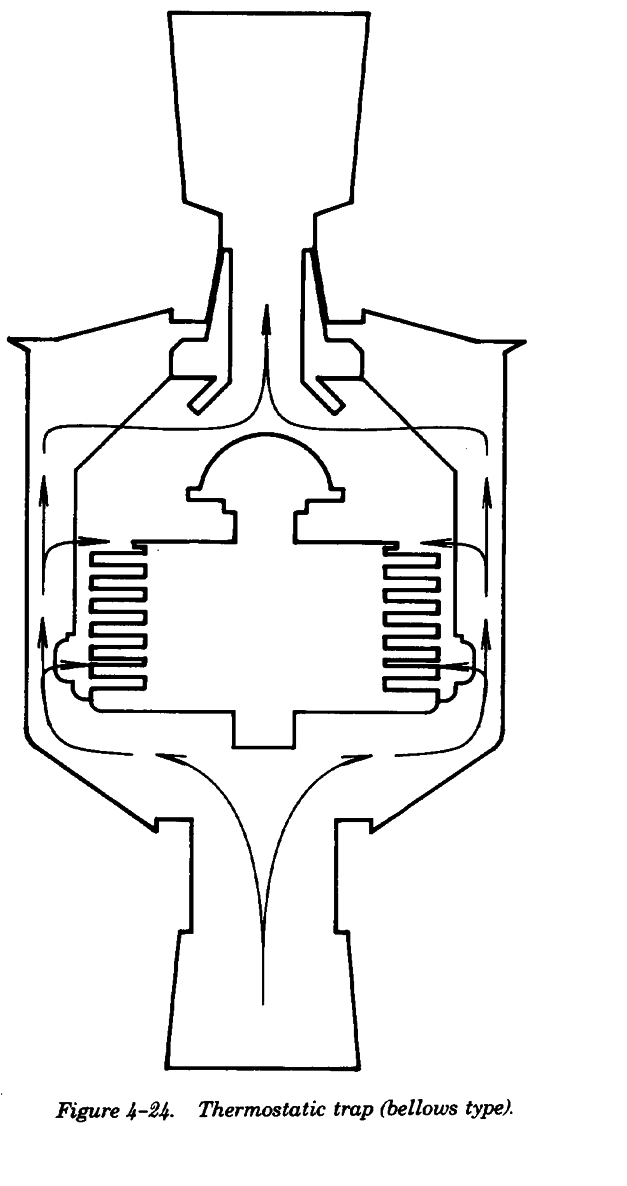

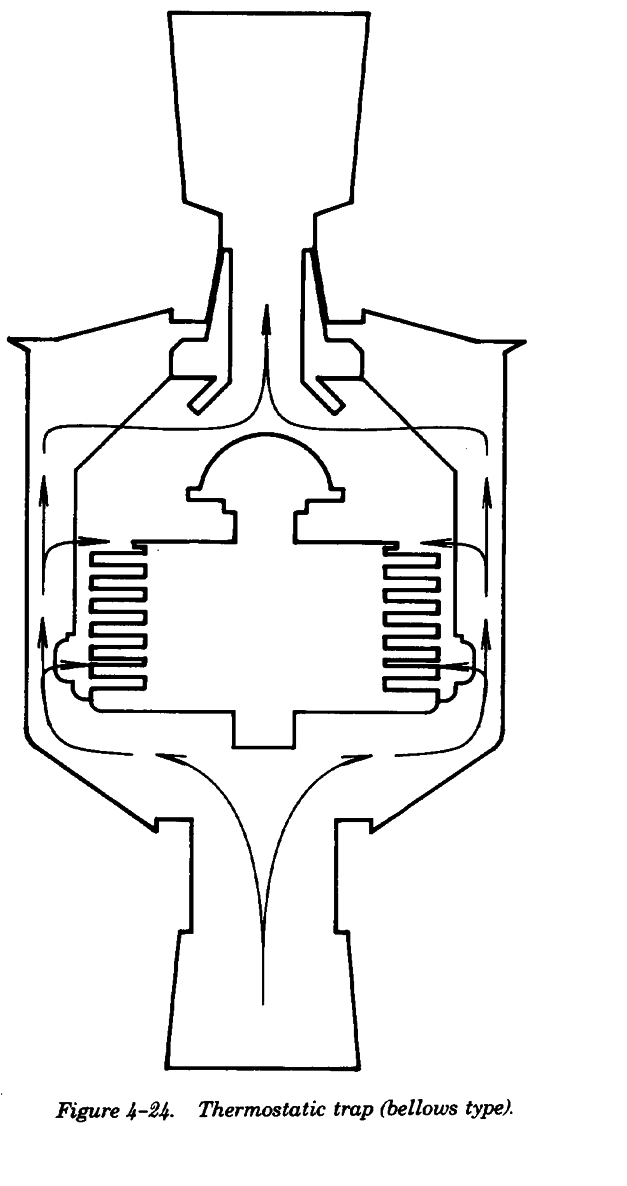

Thermostatic traps are varied in design detail but

are classified as bellows or diaphragm type based

on the kind of expansion element used. (See figures

4-24 and 4-25).

4-34

TM 5-642

each radiator valve and remove the cap of each

thermostatic trap after the thermostatic unit has

cooled. Do not open thermostatic traps when they

are hot or when high vacuum is present in the

returns, since permanent distortion may occur to

the diaphragm or bellows. After the cap is removed

clean the trap interior, valve, and seat carefully with

a clean cloth. Do not clean seats, valve discs or

heads with abrasives, emery cloth, or files as

permanent scoring may result. It is important to

clean the trap during initial periods of new plant

operation as often as necessary and also im-

mediately following the shut-down of the heating

system for summer lay-up.

(5) When removing caps, use wrenches fur-

nished by the trap manufacturer to avoid damage to

heads and caps. Before replacing caps, carefully

wipe the threads clean and coat lightly with oil.

b. Maintenance.

(1) Clean the interior of thermostatic traps, in-

cluding diaphragm, valve seat and heads as required

by manufacturer*s instructions or as often as

required if water conditions cause excessive deposit

of solids, greases, or scale.

(2) A simple inspection check of the diaphragm

or bellows is accomplished by shaking the

diaphragm near the ear. Note by sound whether or

not the diaphragm contains liquid. Pull the valve

head to expand the thermostatic element slightly

and then compress to detect the sound of air or

liquid leaks. If the diaphragm or bellows leaks, it

must be replaced with a new element. Do not refill

Figure 4-25. Thermostatic traps (diaphragm type).

diaphragms, or patch and solder leaks, since

a. Installation.

charging and closing thermal elements requires a

(1) It is important to install traps so that the

factory process with exact procedures and

trap inlet is at or below the steam chamber and to

exceedingly close tolerances.

connect the discharge opening to the return piping

(3) If the valve head is damaged or scored,

so that condensate will return by gravity to the

remove it from the thermal element and replace it if

steam main. Thermostatic traps do not lift or siphon

possible; otherwise, install a new diaphragm or

condensate from a steam radiator. The top water

redress with special tools which are available from

line of a trap should be the top water line in the

the trap manufacturer. To regrind trap seats or

steam space served by the trap to ensure proper

discs, it is necessary to shim the diaphragm in re-

condensate drainage. Lower heat emission and

setting, with shims available from the manufacturer

efficiency of a heating unit may result due to partial

to compensate for metal removed from the valve

filling of the steam space by water which is backed

head or seat. Do not regrind or cut valve seats of

or held in the heating unit by a clogged or defective

the replaceable type, since the trap setting is

trap or a trap set too high.

disturbed by excessive removal of metal.

(2) The thermostatic trap is set so that the axis

c. Typical operating difficulties. Faulty traps

of the bellows or diaphragm is vertical to assure

will cause readily discernible operating difficulties.

that the thermostatic element is not partly immersed

Radiators will fail to heat due to air binding. This

in condensate.

may be caused by clogged traps or burst dia-

(3) The return pipe connections should be ar-

phragms. Bellows expand on release of their inter-

ranged so that expansion and contraction of the

nal vacuum and close the valve. Return lines

mains does not place strains on the trap.

become excessively hot due to cut valves and seats

(4) After the heating system piping, boilers and

which allow excessive steam leakage into return

other equipment are cleaned and in operation, shut

mains. Radiators will pound or have considerable

4-35

TM 5-642

water surging sounds when the trap lacks capacity,

thermostatic element of a radiator trap and is either

when trap is not properly set at the bottom of

built directly into the body of the trap or into a

eccentric radiator outlet bushings, or when the trap

radiator trap placed in the bypass over the float

is clogged. Defective traps should be returned to

element. The float element and the thermostatic

manufacturers for repair or replacement.

element have separate orifices, each discharging to

the return outlet of the trap. There are two types of

4-46.

Float and thermostatic traps and bucket

bucket traps, open inverted buckets, and open

traps.

upright buckets. These have various linkages to

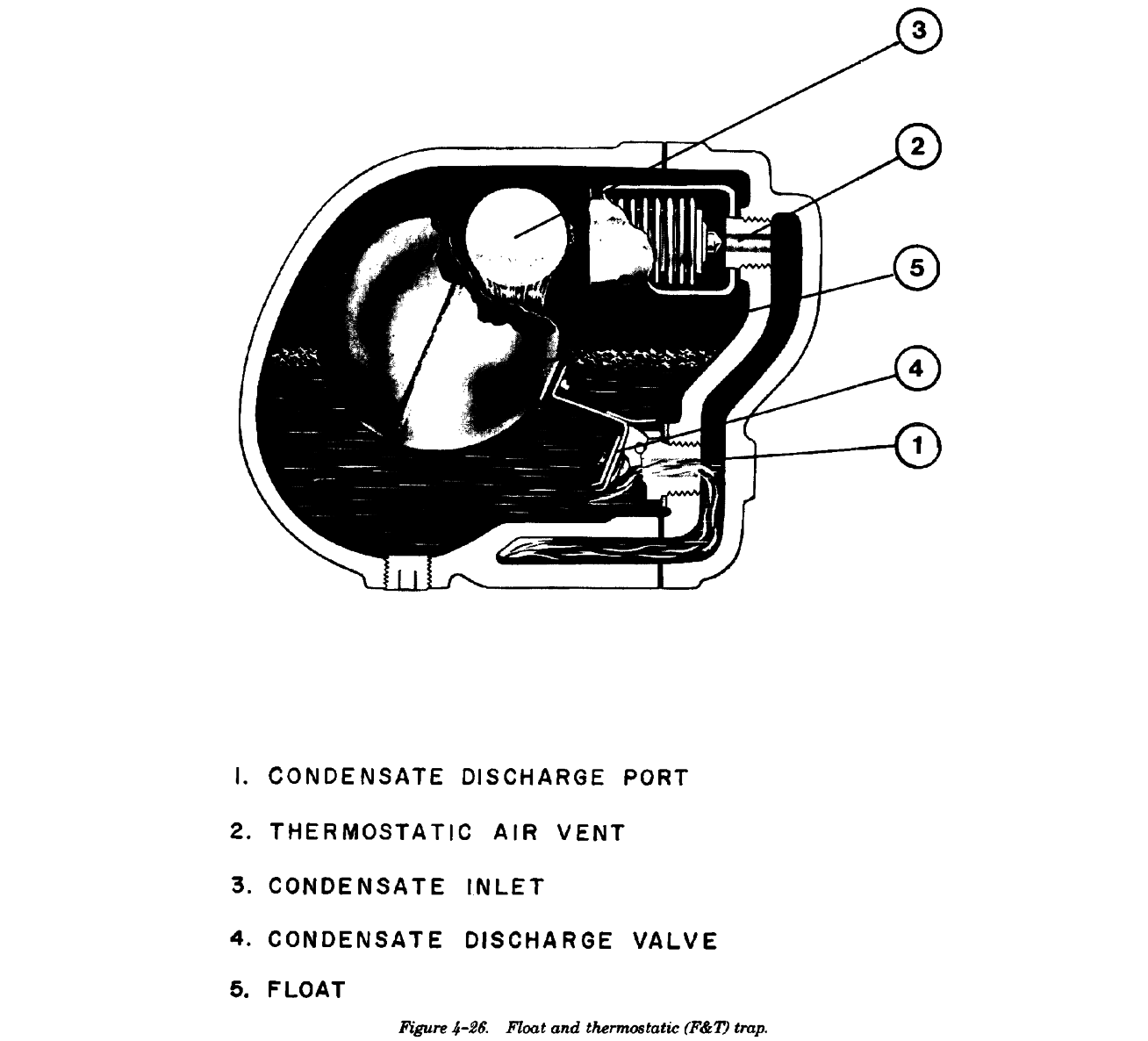

These traps are installed on high capacity heating

transmit the bucket action to the valve. These traps

units such as unit heaters, blast coils, and hot water

discharge condensate intermittently. The linkage or

supply heaters. F&T traps are also used to drip

leverage system should operate so that any

ends of steam mains of closed vapor and vacuum

pulsating action of the float is not transmitted to the

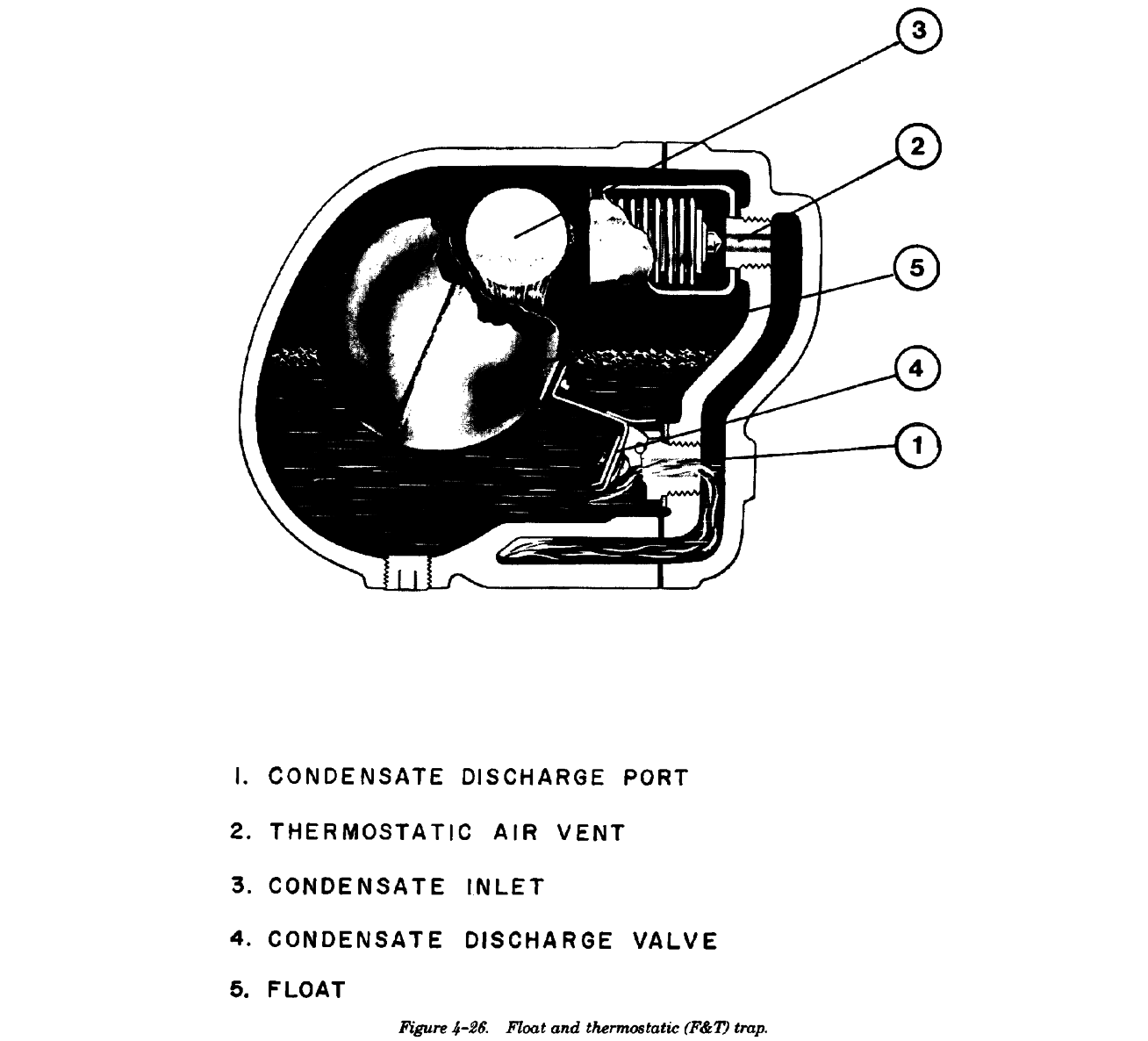

heating systems. F&T traps consist primarily of two

valve since this would cause leakage and wire

elements: the float section which is intended to

drawing of the valve and seat. The valve opening is

handle the condensate, and the thermostatic

either located at the bottom or the top of trap unit.

element which consists of a diaphragm or bellows

A valve opening situated on top of the trap unit is

unit to pass air and gases. (See figure 426). The

preferable since it eliminates stoppage by scale or

thermostatic element is an exact duplication of the

other entrained matter.

4-36

TM 5-642

a. Installation. Float traps will not siphon or lift

other equipment which have readily accessible

condensate. The float trap must be installed so that

steam shutoff valves at the supply connection, need

the top water line of the trap is below the bottom of

not be provided with shutoff valves.

the equipment to be drained. The float trap must be

b. Operation and cleaning. After completion of

set level to eliminate binding of the leverage

replacement, remove any temporary blocks or ties

system. Trap connections at the end of mains

which are present to hold the float mechanism

should include a shut-off valve, vertical drop or dirt

during shipping and installation. If the trap is

pocket, strainer, and finally a drop into the return

equipped with a priming plug, open and fill the trap

main. The bottom of the dirt pocket should be fitted

with water. If a priming plug is not provided, open

with an easily removable cap for blowdown and

the valve to the steam line or heating unit supply

removal of dirt, scale, and grease. Float traps

valve and allow the trap to prime as condensate

installed on unit heaters or

accumulates in the body. This process may entail a

4-37

TM 5-642

short period of steam leakage. Open caps of

condensate could result in freezeup of extended

strainers and dirt pockets preceding traps at

surface coils used in ventilating work and of other

frequent intervals, or as indicated necessary, to

steam units exposed to ambient conditions. Keep a

assure removal of any accumulation of grease and

shop supply of serviced traps for quick replacement

scale. After traps have been in service on new in-

so that equipment need not be shut down during

stallations for a short period, remove covers, valve

repair operations.

head and seat, and wipe the internal mechanism

d. Typical operating difficulties.

thoroughly with a clean cloth to remove initial

(1) Steam leakage or blowby is the most

grease, scale, and accumulations of core sand. Peri-

common difficulty and is caused by float failures, a

odic opening of the trap drain plugs and blowdown

worn linkage or lever system, cut valves, or exces-

is effective in maintaining good trap service.

sive accumulations of dirt, rust, scale, and grease.

c. Maintenance. Check traps frequently to be

(2) Pounding and noise (water-hammer) in a

sure that they are operating properly. A correctly

heating unit or steam main indicates backup of

operating trap has a definite open and closed posi-

condensate due to inadequate trap capacity. Steam

tion, and the sound of condensate flow and shutoff

traps should be sized for 250 percent of the heating

can be detected easily by listening closely at the

unit capacity to permit excess condensate removal

discharge piping of the trap. Use a stethoscope to

during cold start-up. Noise is also caused by

check trap operation. Holding the stethoscope to

clogged traps or defective or jammed float mecha-

the trap body in the area of discharge provides a

nisms.

satisfactory method for checking trap performance.

(3) Air binding due to failure of the thermosta-

Repair or replace a trap immediately upon detection

tic element causes heating equipment failure and is

of blowing steam. This condition disrupts

usually detected by a relatively cool area preceeding

functioning of the heating system and further

the trap. Air binding creates an air pocket which

damage to the trap will result because of the cutting

prevents steam from filling the steam space of the

action of wet steam and condensate flowing

heating unit and the top of the trap. When this

through a scored or restricted opening. Blowing or

condition is present, backing off the thermostatic

leaking traps will also cause excessively hot returns.

element cover or opening the cleanout plug will

Inspect operating elements periodically; float

result in a rush of air followed by a rush of

failures or leakage of the ball or other closed type

condensate and steam. To correct this condition,

floats closes the valve and causes backup of

service the thermostat unit which may be either

condensate. Failure of an upright open bucket trap

clogged or closed by a ruptured thermostatic element.

element results in blowby but not in backup of

condensate. This failure is safe since backup of

Section X. AIR VENTS

4-47.

General.

ator in hot water systems. Vents at ends of steam

Air vents installed on radiators and ends of mains of

mains, unit heaters, and the like are usually of the

gravity heating systems consist of a combination

vertical straight shank type and are installed at the

thermostatic and float actuated valve stem and

top of a vertical pipe extension. The usual type vent

orifice, usually housed in a sealed casing. Some air

is sealed so that on-the-job repair is not practical.

vents include an adjustable orifice to increase or

Therefore, when placing a vent in initial operation,

decrease the vent rate, which provides for balancing

be careful not to force or inject excessive amounts

of the heating system.

of grease or scale into the vent.

4-48.

Installation and operation.

4-49.

Maintenance.

Vents, when installed on radiators, are located at

Remove vents from the system during the off-heat

the end opposite the steam connection. Radiators

season and allow to soak in a container of kerosene

for use with steam and hot water often have two

for approximately 24 hours to loosen rust and

vent tappings, one near the top and the other ap-

grease; then place in a vertical position, drain

proximately one third of the way down from the

thoroughly, and allow to dry. Air pressure is very

top. The lower opening is used for steam systems,

effective in blowing out vents following the kero-

since this is the location at which air will pocket

sene soaking process. When using air pressure for

between the top and bottom radiator section con-

removing dirt, use proper goggles for eye protec-

nections. The top opening is used to vent the radi-

tion.

4-38

TM 5-642

4-50.

Typical operating difficulties.

heating unit. If unsatisfactory vent performance

The most apparent failure occurs when a vent

cannot be corrected by cleaning procedures, replace

spouts water and steam caused by dirt on the valve

the vent. Manufacturers usually maintain a repair

or opening, by failure of the thermal element or by

service; consult the manufacturer for details of

a bent connection in a water pocket of the piping

factory servicing of vents when a quantity of

system. A clogged vent could result in air binding

defective units have accumulated and repair is

which would prevent steam from entering the

beyond the scope of local repair facilities.

Section XI. STEAM RADIATORS

4-51.

General.

flooring; legless radiators are firmly fixed to wall

There are two types of radiators: cast iron and ex-

brackets. Radiators are normally installed directly

tended surface units. Extended surface units are

under windows or at outside walls to offset

made up of relatively small tubes onto which metal

transmission and infiltration losses and provide

fins are formed. The tubes of extended surface units

comfortable room conditions. Reflectors can be

are either continuous or set in headers and the tube

provided behind radiators to get maximum heat

element is placed in a metal cabinet or enclosure

output, covering them should be avoided.

with circulating grilles at the top and bottom.

4-53.

Initial operation and cleaning.

4-52.

Installation.

After new radiators have been in service for a short

It is extremely important that radiators pitch toward

time, open and clean out thoroughly through the

the condensate discharge opening, particularly if the

return opening. Clean the outside of radiators

radiator is of the extended surface type. Radiator

frequently to maintain maximum heat output.

traps applied to extended surface radiators must be

in perfect operating condition; slight holdup of

4-54.

Typical operating difficulties.

condensate will greatly reduce the effectiveness of

Failure to heat due to stoppage or defective piping

this type of heating unit which has relatively small

causes radiator operating difficulty. Air binding will

available steam space. Traps of extended surface

also prevent radiators from heating properly. See

radiators are placed at an elbowed down

Section X on air vents. If radiators heat but no rise

connection, so that the trap is below the steam

occurs in room temperature, calculate the room

space to facilitate cleaning. Swing-through double-

heat loss and compare it with the quantity of

elbow joints should be used and ample length in

installed radiation. Reduce heat loss, if possible, by

supply and return branches to radiators should be

stopping cold air leaks through cracks, doors, and

provided so expansion and contraction of mains

windows of the area being heated. If radiator

will not cause breakage of radiator connections.

output is still insufficient, relocate radiation units or

Cast iron radiators require a firm setting on solid

install additional units.

Section XII. STEAM UNIT HEATERS

4-55.

General.

unit is increased. It is preferable to set the

Unit heaters consist primarily of an extended sur-

horizontal discharge to blow toward an outside wall

face steam coil and a propeller or blower fan which

at a large angle and to discharge all units in the

creates rapid flow of air through the heating coil.

same direction to form a continuous circuit of air

The basic types are horizontal and vertical

around exposed walls. Units placed in small rooms

discharge from ceiling suspension (figures 4-27 and

with low ceilings may be located on outside walls

4-28) and floor mounted horizontal blower units

with a recirculating duct to the floor to provide

(figure 4-29). Units are rated in BTU per hour or

even heating effects without undue draft conditions.

equivalent direct radiation (EDR) heat output and

Vertical discharge units are usually placed at room

cubic feet per minute air discharge capacity at given

ceiling or structural members and, since they