246

Microsensors

1μm

θ

Fig. 12. Definition of fracture surface (mirror zone) angle.

] 3

sing

a mP

s ues [M

hn

IC 2

K

touge one,

tur

or z

L15R1

rac

irr 1

L15R2

d m

L15R3

ated f

L15R4

cul

ss an

L15R5

alC

h = 3.5 µm

stre 00

10

20

30

40

Angle between fracture surface and

principal stress surface [deg.]

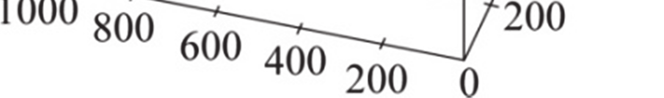

Fig. 13. Angle dependency of fracture toughness ( h = 3.5 [μm]).

5. Effective area and application to design

5.1 Effective area definition and calculation results

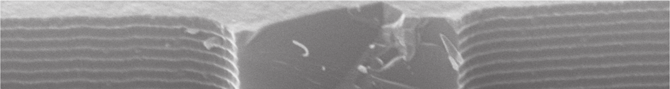

The stress concentration factors on the specimen surface were determined based on the

result of surface roughness measurement by AFM. As shown in Fig. 2, difference occurs in

the surface shape of the upper surface and the sidewall surface by the difference in the

manufacturing technique. Figure 14 indicates an example of the difference in surface

Strength Reliability of Micro Polycrystalline Silicon Structure

247

roughness of the h = 6.4 [μm] specimen obtained by AFM, and Fig. 15 indicates the example

of surface section of the scarop bottom on the sidewall surface.

Using the measurement result of the surface roughness, the stress concentration factors Kt of

the specimen were calculated. As shown in Fig. 14, the appearance present complicated

shapes, therefore FEM analysis is necessary to calculate an accurate stress concentration

factors. In this report, in order to simplify, the interference effects by the multiple notches

were ignored and the stress concentration factors Kt were determined from width ( a) and depth ( b) from the roughness measurements using the following equations supposing the

equivalent ellipse as shown in Fig. 15.

2

= 1 +

(4)

The maximum stress concentration factor Kt max which exists in a specimen based on the data

of the measured stress concentration factor is estimated using the statistics of extreme.

Figure 16 shows the extreme values probability paper. The horizontal axis is the stress

concentration factor Kt j obtained by the Eq. (4). The vertical axis is the reduced variates yj calculated by the following equation which is a formula of the statistics of extreme.

=

,

= − ln − ln

+ 1

(5)

( j = 1, 2, 3,…, n n: Number of inspections)

The approximate expression was calculated using the least square method from the

obtained distribution. The maximum stress concentration factor which substitutes the return

period T for the following equations, and Kt max exist in a specimen is estimated.

− 1

= − ln − ln

, = α

+ β

(6)

When determining the return period T, evaluation area was made equal to the effective area.

The relation between evaluation area and the return period are defined using the following

equations. ( S 0: inspection area)

+

=

,

< 10

(7)

=

,

> 10

(8)

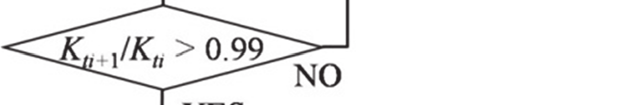

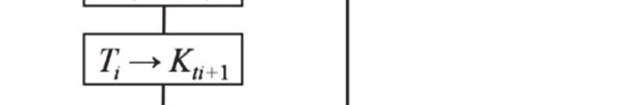

In order to bring evaluation area close to an effective area, calculation performed repeatedly.

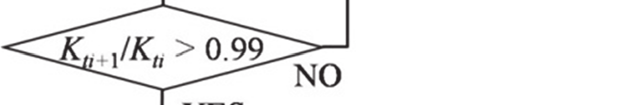

The computational procedure is as follows. Fig. 17 indicates a computational procedure outline.

1. Define T 0 by the evaluation area to the extent of the whole specimen is included enough

2. Calculate Kt i from defined T 0

3. Calculate assumed effective area Si from Eq. (1) and FEM

4. Calculate Ti, Si as evaluation area

5. Calculate Kt i+1 from Ti

6. Compare Kt i and Kt i+1. If Kt i/( Kt i+1) > 0.99, then define Si as effective area 7. If not Kt i/( Kt i+1) > 0.99, repeat the process after 3).

248

Microsensors

(a) Top surface (b) Sidewall surface

Fig. 14. Surface morphology of top and sidewall (unit: nm) ( h = 6.4 [μm]).

Fig. 15. Surface roughness example of sidewall (Fig. 14 A-B).

99.9

Top surface

%

99

ility F, ab

Sidewall

ob

surface

90

tive pr

50

ulam

10

Cu

1

0.1

1.0

1.5

2.0

2.5

Stress concentration factor K t

Fig. 16. Variation of stress concentratio

Fig. 17. Schematic diagram of deciding S

factor Kt.

from T and Kt ( h = 6.4 [μm]).

Strength Reliability of Micro Polycrystalline Silicon Structure

249

Maximum stress

Effective

Specimen

concentration factor

area

type

Kt max

S [μm2]

Top surface Sidewall surface

L15R1 1.22

1.79

4.02

L15R2 1.28

1.82

8.01

L15R3 1.34

1.84

13.7

L15R4 1.39

1.86

22.7

L15R5 1.39

1.85

22.8

L10 1.20 1.78 3.57

L15 1.21 1.78 3.47

Table 2. Result of calculations, Kt max and S ( h = 6.4 [μm]).

In this study, it calculated as initial return period value T 0 = 10000. Table 2 shows the

obtained Kt max and S.

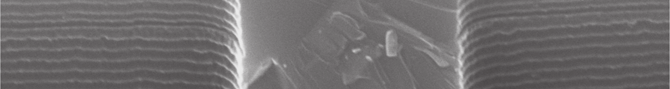

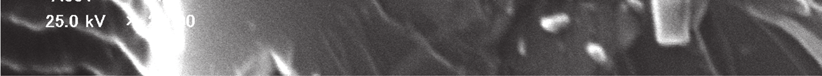

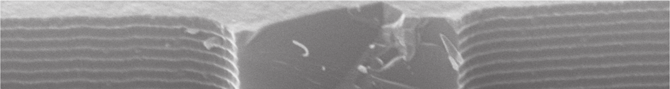

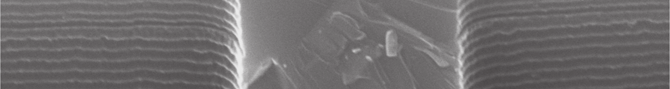

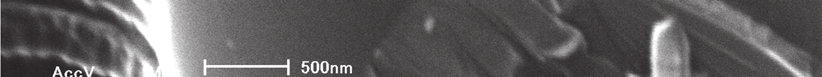

5.2 Effective area and fracture origin

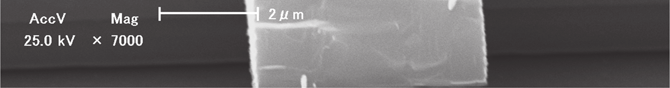

Figure 18 indicates the example in the structure of the effective area. Figure 18 shows that

the region of effective area where fracture origin may exist has extended to the specimen

sidewall. Fracture surface observation of the specimen was carried out, and the example to

which fracture origin exists in the sidewall was observed. Figure 19 shows an example. The

scattering in fracture origin is shown in Fig. 20. It turns out that fracture origin varies within

an effective area.

Fig. 18. Calculated effective area S (Specimen type: L15R5, h = 6.4 [μm]).

5.3 Application to design

Bending strength (maximum stress σmax at the time of fracture) σB and the maximum stress

concentration factor Kt max were fitted to the Eq. (1) and the effective area was determined.

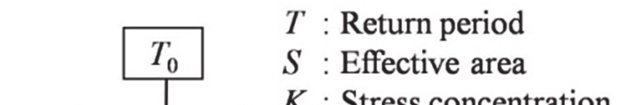

Figure 21 shows the relationship between bending strength and the effective area. Average

values of the test data ( N = 8) were used for σB . The tendency bending strength becomes

small as the effective area increased can be seen.

The equation of Weibull distribution which generally took the effective volume V into

consideration same as Section 3 is shown as follows.

250

Microsensors

σ

= 1 − exp −

(9)

σ

Eq. (9) can be expressed as follows.

1

ln ln

=

ln σ − ln σ + ln

1 −

(10)

It turns out in the Eq. (10) that the effective volume V acts as a value which does not involve at the shape parameter m which shows the level of scattering. Since an effective volume did

not participate in scattering, it extrapolated to the reliability needed for a design using the

average of the shape parameter determined from the experimental result σB. In Fig. 21, an

extrapolation example in the case of F = 0.001, the relationship between σB and S are shown.

Fracture origin

2μm

0.5μm

(a) Whole fracture surface (b) Magnification of fracture origin

Fig. 19. Fracture origin on the sidewall surface ( h = 6.4 [μm]).

(a) Before test

(b) After test, σB = 3.15 [GPa]

5μm

(c) After test, σB = 3.41 [GPa]

(d) After test, σB = 3.67 [GPa]

Fig. 20. Variation of fracture points, Specimen type: L15R5, h = 6.4 [μm].

Strength Reliability of Micro Polycrystalline Silicon Structure

251

10

a

Experimental result, F = 0.5

, GP B 5

th

treng

Extrapolation result, F = 0.001

g sin 2

endB

11

2

5

10

20

50

100

Effective surface area S , µm2

Fig. 21. Relationship between the bending strength and effective area

6. Conclusion

In order to propose the static strength design criteria of the poly-Si structure which has a

microscopic dimension, the bending test, surface roughness measurement, FEM analysis,

the Weibull statistical analysis, statistics of extreme analysis, and fracture analysis of a

cantilever beam were conducted.

The obtained results are as follows.

1. By Weibull analysis, we found that the scatter in poly-Si bending strength made by RIE

process is smaller than that of DRIE process.

2. Poly-Si strength is scattered. It depends on surface condition, crystal or grain boundary

direction and some other.

3. The definition method of the quantitative effective area in bending cantilever beam was

shown to the poly-Si with which the surface roughness on the upper surface and the

surface of the sidewall differs.

4. Bending strength depends on the effective area definition are shown.

5. The static strength design criteria in consideration of the scattering in the strength using

two parameters, the bending strength (maximum stress at the time of fracture) and the

effective area, was proposed.

7. References

Chen, K. S.; Ayón, A. A.; Zhang X. & Spearing, S. M. (2002). Effect of Process Parameters on

the Surface Morphology and Mechanical Performance of Silicon Structures After

Deep Reactive Ion Etching (DRIE), IEEE Journal of Microelectromechanical Systems,

Vol. 11, No. 3, pp. 264-275, ISSN 1057-7157

252

Microsensors

Greek, S.; Ericson, F.; Johansson, S. & Schweitz, J.-Å. (1997). In situ tensile strength

measurement and Weibull analysis of thick film and thin film micromachined

polysilicon structures, Thin Solid Films, Vol. 292, pp. 247-254, ISSN 0040-6090

Gumbel, E. J. (1962). Statistic of Extremes, Columbia Univ. Press, New York

Hull, D. (1999). Fractography, Cambridge University Press, ISBN 0521640822, Cambridge, pp.

121-129.

Johnson, L. G. (1964). The Statistical Treatment of Fatigue Experiments, Elsevier, New York

Kahn, H.; Tayebi, N.; Ballarini, R.; Mullen R. L. & Heuer, A. H. (2000). Fracture toughness of

polysilicon MEMS devices, Sensors and Actuators A, Vol. 82, pp. 274-280, ISSN 0924-

4247

Kapels, H.; Aigner, R. & Binder, J. (2000). Fracture strength and fatigue of polysilicon

determined by a novel thermal actuator, IEEE Transactions on Electron Devices, Vol.

47, pp. 1522-1528, ISSN 0018-9383

Muhlstein, C. L.; Howe R. T. & Ritchie, R. O. (2004). Fatigue of Polycrystalline Silicon for

Microelectromechanical Systems: Crack Growth and Stability under Resonant

Loading Conditions, Mechanics of Materials, Vol. 36, pp. 13-33, ISSN 0167-6636

Murakami ,Y. Eds. (1992). Stress Intensity Factors Handbook Vol.3, Soc. Materials Sci., Japan & Pergamon Press, pp. 591-597

Najafi, K. (2000). Micromachined Micro Systems: Miniaturization Beyond Micro-electronics,

Proc. 2000 Symposium on VLSI Circuits Digest of Technical Papers, pp. 6-13

Namazu, T.; Isono Y. & Tanaka, T. (2000). Evaluation of Size Effect on Mechanical Properties

of Single Crystal Silicon by Nano-Scale Bending Test using AFM, IEEE Journal of

Microelectromechanical Systems, Vol. 9, pp. 450-459, ISSN 1057-7157

Senturia, S. D. (2000). Microsystem Design, Kluwer Academic Publishers, ISBN 0792372468,

Dordrecht

Sharpe Jr., W. N.; Jackson, K. M.; Hemker K. J. & Xie, Z. (2001). Effect of Specimen Size on

Young's Modulus and Fracture Strength of Polysilicon, IEEE Journal of

Microelectromechanical Systems, Vol. 10, pp. 317-326, ISSN 1057-7157

Son, D.; Kim, J.; Lim T. W. & Kwon, D. (2004). Evaluation of fracture properties of silicon by

combining resonance frequency and microtensile methods, Thin Solid Films, Vol.

468, pp. 167-173, ISSN 0040-6090

Tsuchiya, T.; Tabata, O.; Sakata J & Taga, Y. (1998). Specimen size effect on tensile strength

of surfacemicromachined polycrystalline silicon thin films, IEEE Journal of

Microelectromechanical Systems, Vol. 7, pp. 106-113, ISSN 1057-7157

Weibull, W. (1951). A statistical distribution function of wide applicability, Transactions

ASME Journal of Applied Mechanics, Vol. 18, pp. 293-297

12

MEMS Gyroscopes for Consumer and

Industrial Applications

Riccardo Antonello and Roberto Oboe

Dept. of Management and Engineering,

University of Padova - Vicenza branch

Italy

1. Introduction

The advent of MEMS (Micro-Electro-Mechanical-System) technology has enabled the

development of miniaturized, low-cost, low-power sensors that are currently replacing

their macroscopic scale equivalents in many traditional applications, covering industrial,

automotive, biomedical, consumer applications, etc.

Competitiveness of MEMS sensors largely resides in the miniaturization and batch fabrication

processes involved in their manufacture, which allow to cut down costs, size and power

requirements of the final device. Moreover, miniaturization opens new perspectives and

possibilities for the development of completely new class of sensors, where micro-scale

phenomena are effectively pursued to achieve results that would be unfeasible at a

macro-scale.

Several MEMS sensor typologies are either commercially available or have been presented

in technical literature since the beginning of the microsystem technology more than 30 years

ago. Pressure and acceleration sensors for the automotive industry have been among the first

MEMS devices to be produced in large scale, and they have contributed to foster the further

development of MEMS technology. Despite their maturity, these sensors are still dominating,

with their sales volume, the market of silicon-based sensors. Recently, another micro-sensor

that is becoming relevant in terms of sales volume, especially in the automotive and consumer

electronics markets, is the angular rate sensor, or gyroscope.

Alongside with accelerometers, micromachined gyroscopes can be used in several

applications that require an integrated solution for inertial sensing and motion processing

problems (Söderkvist, 1994; Yazdi et al., 1998).